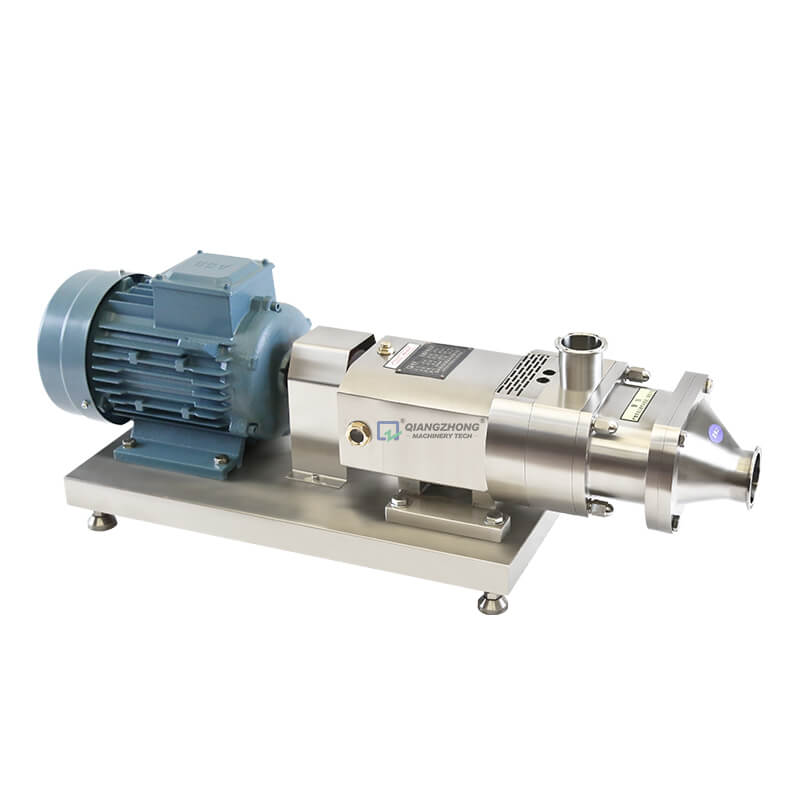

100% Original Factory Soys Milk Processing Equipment - Water and powder mixer – Qiangzhong Detail:

Powder Liquid Mixer

We specialize in manufacturing food and medical equipment, and know you better!

This product is widely used in food, beverage, pharmaceutical, bioengineering, water treatment, daily chemical, petroleum and chemical industries

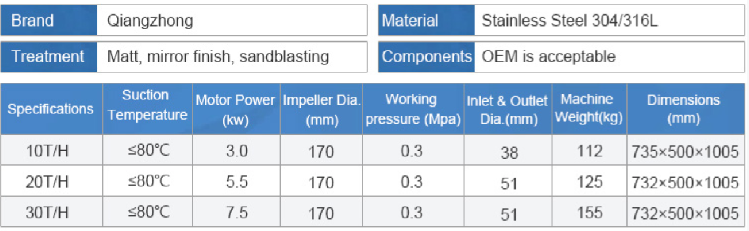

Product Parameters

Product Structure

The pump is mainly composed of feeding hopper, butterfly valve, pump casing I, II, impeller, main shaft, mechanical seal, water cooling jacket, pump seat, belt transmission device, motor, etc. All parts of the equipment that are in contact with the materials are made of high-quality and corrosion-resistant stainless steel, which meets food health requirements. When the device is working, the motor drives the main shaft and the impeller through the belt, and the impeller rotates at a high speed in the pump casing II to achieve the purpose of mixing the liquid. The impeller is made of Ocr19N19, which is easy to take apart and wash, and it prevent bacteria from gathering. The mechanical seal is composed of a static ring, a dynamic seal ring, a stainless steel spring and a compression seal ring. There is also an external seal that prevents liquid leakage. The main shaft and the motor are driven by a V-belt, and the pump is equipped with a water cooling jacket and a tensioner The motor and wiring part of this pump can effectively prevent the accumulation of water and damp, and it is in line with electricity safety. The motor and the pump base are connected by bolts, which makes the whole machine can be moved arbitrarily without a fixed installation foundation.

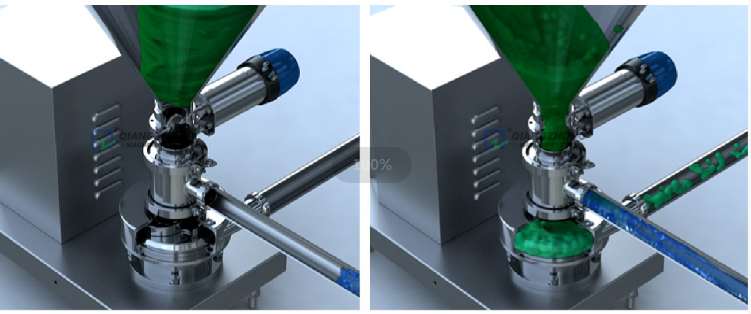

Working Principle

The mixture pump is also called water powder mixer, liquid material mixer, liquid material mixing pump, etc. It has the advantages of unique appearance, compact size, environmental protection and cleanliness, energy saving, high efficiency, rapid mixing and convenient transportation. The equipment is to fully mix the powdery material and liquid through a high speed rotating impeller to make it a required mixture and send it out. And it can absorb materials with a maximum temperature of 80 degrees. It can quickly mix the liquid material and can be used for the production of fruit juices and other beverages to achieve the desired benefits.

The pump consists of a main body and an impeller, which are mounted perpendicular to each other. It sucks liquids and solids separately through a double-walled pipe, preventing them from clumping before entering the main part. The liquid enters the main body of the pump at high speed and at the same time a vacuum is generated at the center of the rotor and the stator to suck solids. By adjusting the valve below the hopper, the solids can be evenly inhaled. The equipment is advanced design, multi-functional, high production efficiency and durable. It can quickly and uniformly mix a variety of solids without contact with the air, and the material is fully mixed and recycled. It can disperse and emulsify materials in the shortest time, narrowing the particle size distribution range, and finally obtaining a fine, long-term stable product.

Maintenance Instructions

Please check whether the seals are correctly assembled and whether the joints are tightly connected before operate the pump. Check whether the rotation direction of the impeller is clockwise. Before operate the pump, parts that come in contact with liquids should be steam sterilized to ensure compliance with food health and safety requirements.

The threaded joint (Rd65 x 1/6) on the pump housing I is the inlet, and the mixed liquid after mixing is transmitted through the threaded joint (Rd65 x 1/6) of the lower pump housing II. The two rubber hose fittings on the lower part of the pump casing II are cooling water inlet pipes designed to cool the mechanical seal and the spindle. In order to avoid that the installation position of the pump is higher than the suction level, which requires an irrigation pump, the pump is preferably installed at a position lower than the liquid level to facilitate the control of the flow. Do not allow the pump to work under long-term overload conditions to avoid damage to the motor.

The dismantling of the pump is convenient. After loosening the 4 M10 cap nuts, the diaphragm of the pump housing I can be opened. Remove the lock nut on the spindle (left-handed, clockwise). Take out the impeller and you will see the mechanical seal. When the pump is running, it should be noted whether there is leakage on the sealing surfaces. If the leakage is severe, stop using it immediately and check if the seals on the shaft are damaged and the installation position is correct. And replace it properly with new one if necessary.

After the operation is completed, the pump should be cleaned in time to prevent the scale of the feed liquid. Use hot water for cleaning first, then remove the pump body, clean the parts with a brush, and then install all the parts in order. Note that when in use and cleaning, the stainless steel motor cover can not be removed to prevent moisture, which will damage the motor.

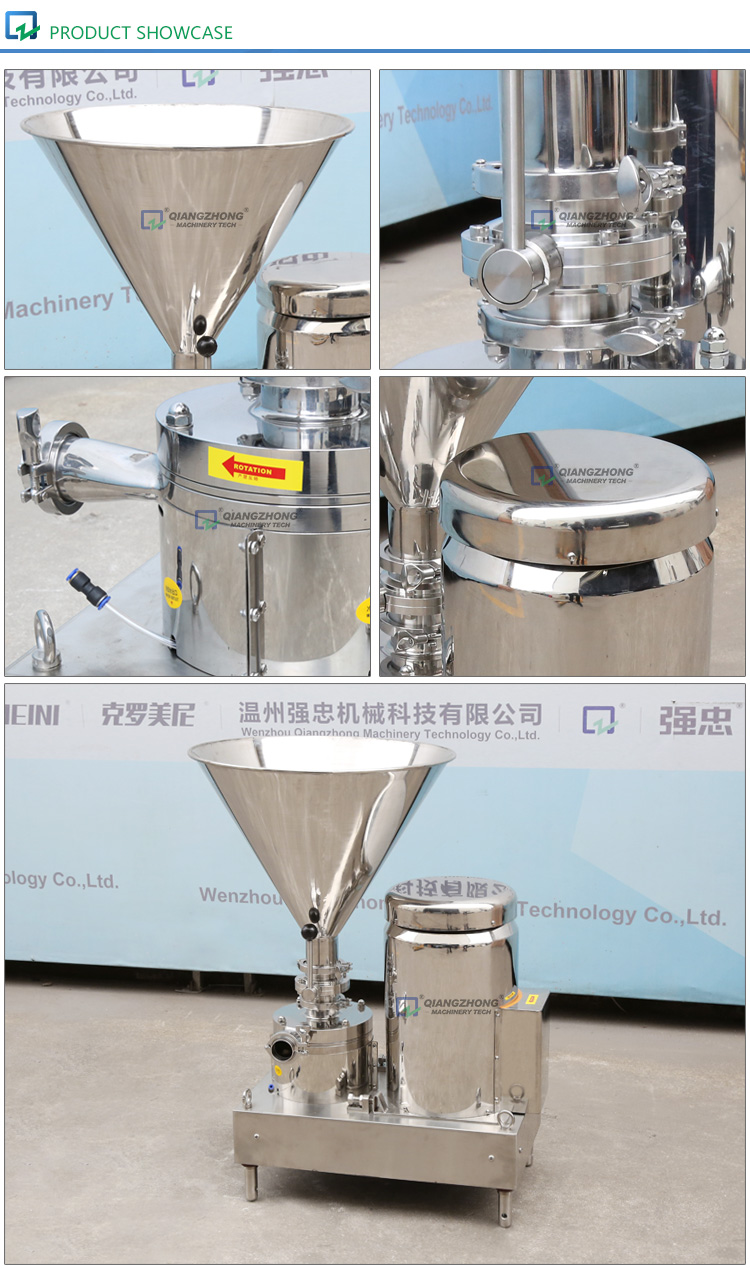

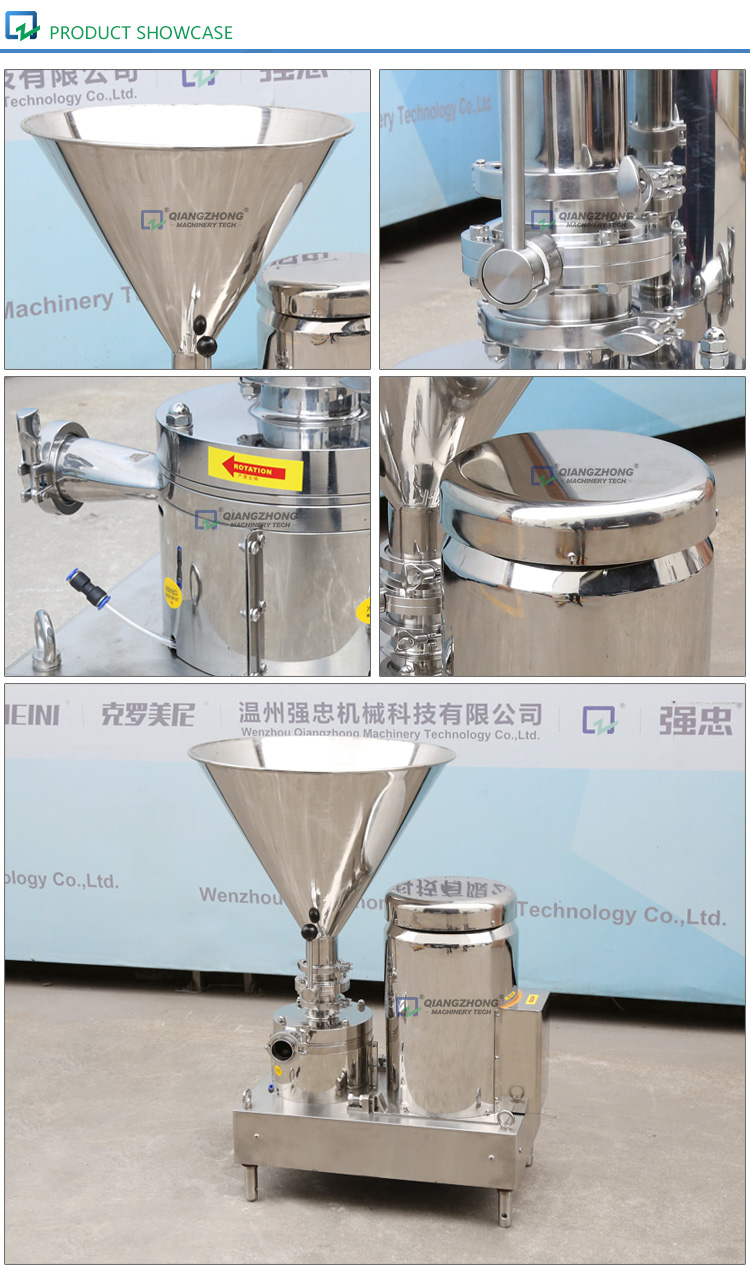

Product detail pictures:

Related Product Guide:

Cooperation

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for 100% Original Factory Soys Milk Processing Equipment - Water and powder mixer – Qiangzhong, The product will supply to all over the world, such as: Bangalore, Swiss, Roman, Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

-

Wholesale Price Centrifugal Water Pump 250kw -...

-

Fixed Competitive Price Automatic Puff Pastry M...

-

Factory Supply Bleaching Earth Oil Filter - Si...

-

High Quality Industrial Autoclave Reactor - Tw...

-

Bottom price Powder Sintered Filter Plate - Pl...

-

China Cheap price Lipstick Melting - Electric ...