Stirring Emulsification Tank 1000L

We specialize in manufacturing food and medical equipment, and know you better! Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries.

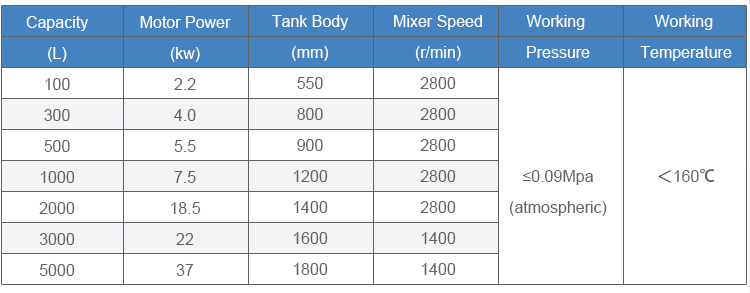

Gl PRODUCT PARAMETERS

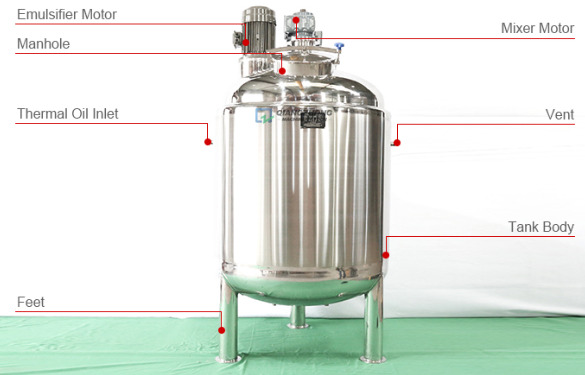

6 PRODUCT STRUCTURE

The tank is capable of distributing one or more phases to another continuous phase efficiently, quickly and uniformly, in which case the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction and impact in the narrow gap between the stator and the rotor. A combination of tearing and turbulence. Therefore, the incompatible solid phase, the liquid phase, and the gas phase are uniformly and finely dispersed and emulsified under the action of the corresponding mature process and an appropriate amount of additives, and the high-frequency cycle reciprocates to finally obtain a stable high-quality product.

- Mixing tank mainly consists of tank body: cover, agitator, supporting feet, transmission device and shaft seal device.

- Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel and other materials according to specific requirements.

- Tank body and cover can be connected by flange seal or welding. Also they could be with holes for purpose of feeding, discharging, observation, temperature measurement, manometry, steam fractionation and safety vent.

- Transmission devices (a motor or a reducer) are installed on top of the cover and the agitator inside the tank is driven by stirring shaft.

- Shaft sealing device can be used machine seal, packing seal or labyrinth seal, they are optional according to customer’s need.

- Agitator type could be impeller, anchor, frame, spiral type, etc.