2021 High quality Ginger Garlic Grinding Machine - 50L laboratory electric heating mixing tank – Qiangzhong Detail:

50L Experimental Electric-heating Mixing Tank

Widely used in industries of brewery, dairy products, beverage, daily chemicals,bio-pharmaceuticals, etc.Mix, disperse, emulsify,homogenize, transport, batch……

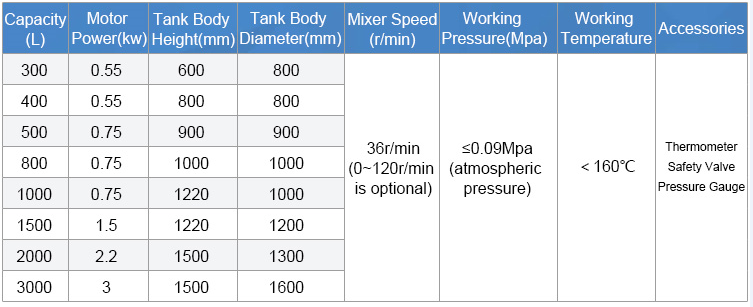

GJ PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

Capacity Motor Tank Body Tank Body Mixer Speed Working Working Accessories (L) Power(kw) Height(mm) Diameter(mm) (r/min) Pressure(Mpa) Temperature

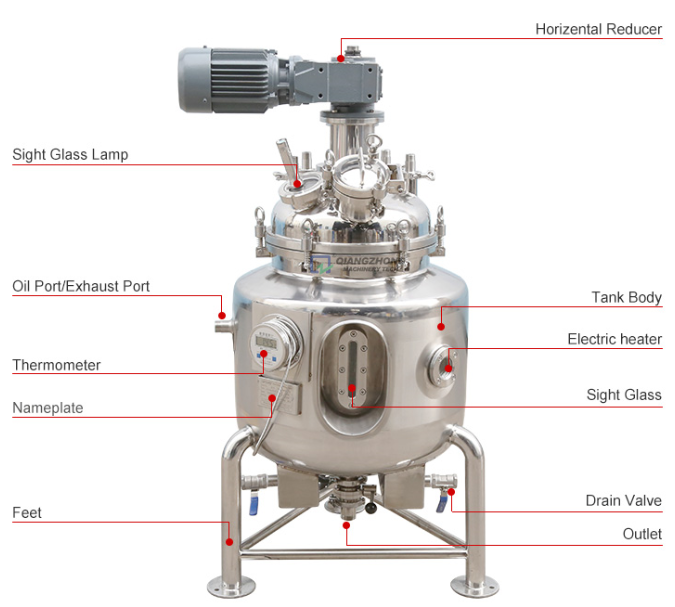

d PRODUCT STRUCTURE

The design and manufacture of the electric heating mixing tank strictly comply with the requirements of GMP. It is economical, safe, high-efficient, hygienic, thoroughly cleaned, easy to disassemble and wash, and has been affirmed by users.

Equipment Structure: upper oval double-opening cover with manhole, lower oval bottom head, bottom discharge, vertical feet.

d PRODUCT STRUCTURE

Main functions of the electric-heating mixing tank: heating (heating the medium in the jacket by the heaters, transferring heat energy, and indirectly heating the material in the tank, with automatic temperature control), heat insulation, cooling and stirring.

Features:

- Stainless steel 304/316L is used for the tank liner and parts in contact with the material The rest of the tank body is also made of stainless steel 304.

- Both the internal and external is mirror polished (roughness Ra<0.4um), neat and beautiful.

- Mixing at fixed speed or variable speed, meeting the requirements of different loading and different process parameters for agitation (it is frequency control, online real-time display of stirring speed, output frequency, output current, etc.).

- Agitator operation state: the material in the tank is mixed quickly and evenly, the load of the stirring transmission system is running smoothly, and the load operation noise <40dB(A) (lower than the national standard of <75dB(A), which greatly reduces the laboratory’s sound pollution.

- The agitator shaft seal is sanitary, wear-resistant and pressure-resistant mechanical seal, which is safe and reliable.

- It is equipped with special equipment to prevent the reducer from contaminating the material inside the tank if there is any oil leakage, very safe and reliable.

- One-third of the upper flat cover is openable and movable, making it easy to feed and clean thoroughly. It is discharged from the bottom of the tank, clean and free of liquid.

- A movable baffle is installed in the tank to meet the mixing and stirring requirements, and there is no cleaning dead angle. It is more convenient to remove and wash it.

- With automatic temperature control, high temperature sensitivity and high precision (with a digital display temperature controller and Pt100 sensor, easy to set up, economical and durable).

- The clamp is applicable for ports, smooth and easy to clean, and also easy to assemble and disassemble.

- Easy to install and use: just plug in the required power cable <380V/three-phase four-wire) in the terminal of the electric control box, then add materials and heating medium to the inside of the tank and the jacket respectively.

Electric Heating Tube Internal Display Instructions

The advantages of the uniquely designed heaters connection:

1. Easy to install the heaters, no need special loading and unloading tools.

2. The heaters are completely filled into the tank body, ensuring a high heating efficiency.

3. Greatly reduce the cost of use and save energy.

Product detail pictures:

Related Product Guide:

Cooperation

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for 2021 High quality Ginger Garlic Grinding Machine - 50L laboratory electric heating mixing tank – Qiangzhong, The product will supply to all over the world, such as: California, Porto, Slovakia, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Low price for Jacketed Vessel With Agitator - ...

-

China OEM Coconut Candy Making Machine - Singl...

-

Top Suppliers Liquid Detergent Mixing Machine -...

-

China Gold Supplier for Food Grade Twin Screw P...

-

Cheapest Factory 200 Liter Steam Jacketed Cooki...

-

Newly Arrival Chili Sauce Making Machine - San...