(Horizontal) Spiral Ribbon Mixing Tank

It is used to mix powdery or pasty materials to make different materials evenly mixed. It is a horizontal trough-shaped single paddle mixing type, and the stirring paddle is a through-shaft type, easy to clean.

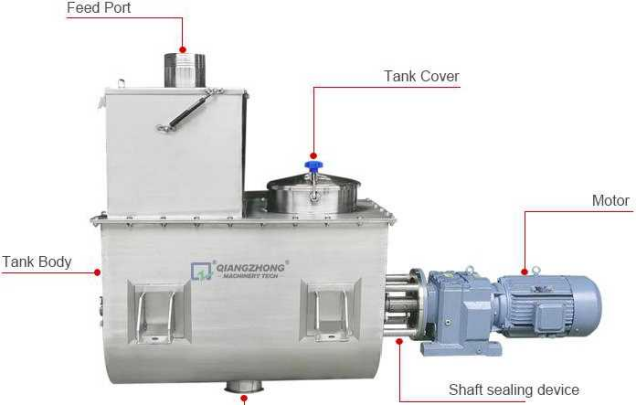

PRODUCT STRUCTURE

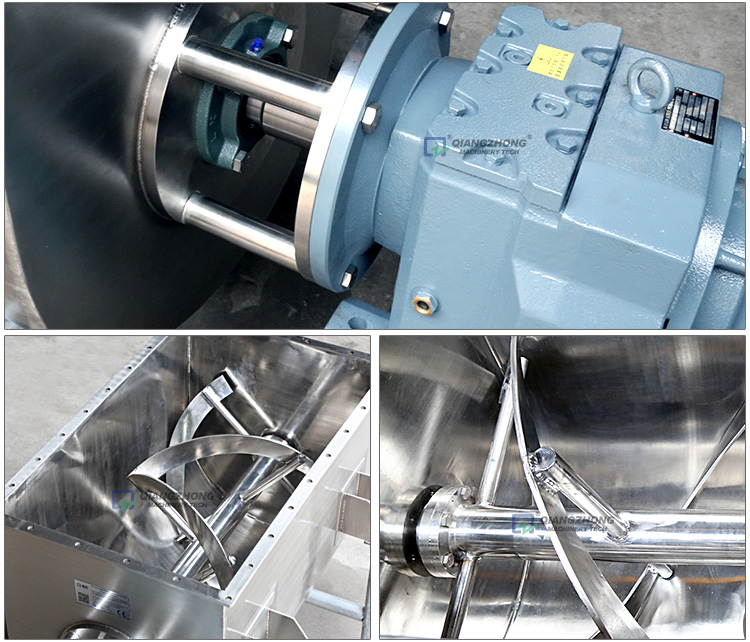

WORKING PRINCIPLE

The double ribbon mixer is driven by a motor and a speed reducer to drive a specially arranged ribbon spindle to rotate. The outer ribbon moves the material to the center position, and the inner ribbon pushes the material to a certain position or end plate. They make the materials do mutual diffusion, convection, shearing, dislocation and radial movement, so that the materials are mixed uniformly in a very short time. There are three types of optional stirring, including continuous ribbon, intermittent ribbon and paddle. They are arranged according to the requirements of center or bottom discharge.

The structure:

Discharging method at the bottom: the manual rotary discharge valve structure is used to process powder materials, which has the advantages of fast discharge and no residue, high-fineness materials or semi-fluid materials are discharged by manual butterfly valves or pneumatic butterfly valves. The manual butterfly valve is economical and applicable. The pneumatic butterfly valve has good sealing performance for semi-fluid, but the cost is higher than the manual butterfly valve

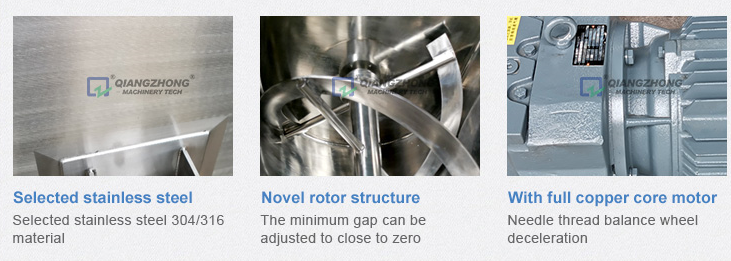

Ribbon type blade:

It is suitable for mixing fluids with high viscosity (over 10O.OOOcp), with good heat transfer and surface effects. There are two types of structure: single spiral ribbon and double spiral ribbon. The number of wings, the pitch and the form of the spiral ribbon can be specially made according to different mixing requirements.