factory Outlets for Stainless Steel Milk Boiling Pot - Chocolate Grinding Mixing Tank – Qiangzhong Detail:

Chocolate Grinding Mixing Tank

Widely used in industries of brewery, dairy products, beverage, daily chemicals,bio-pharmaceuticals, etc.Mix, disperse, emulsify,

homogenize, transport, batch……

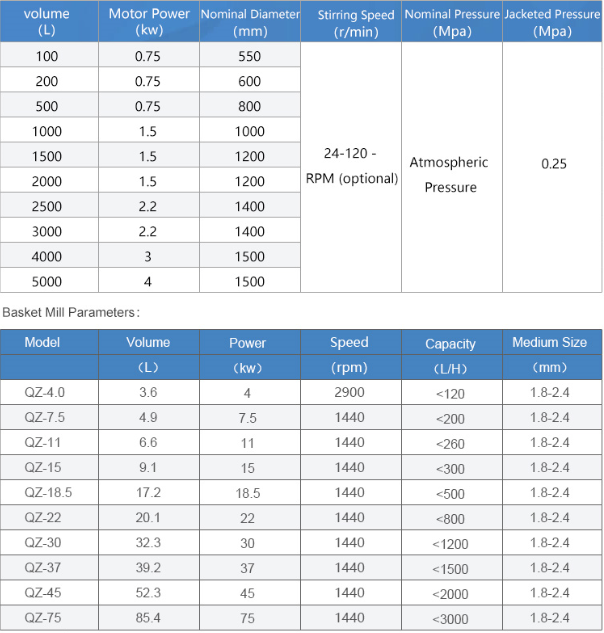

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

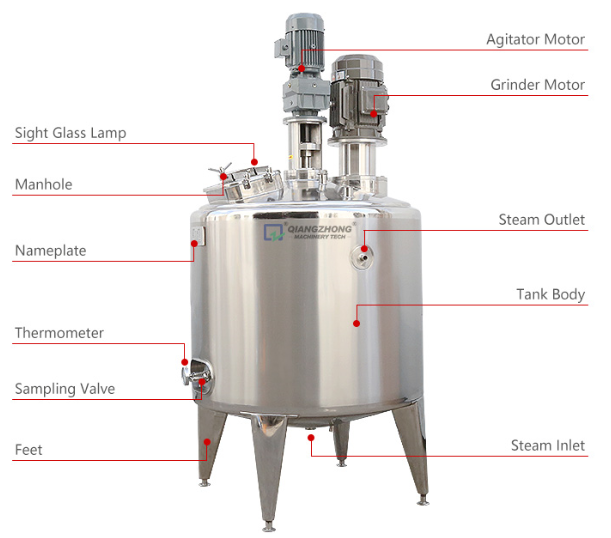

PRODUCT STRUCTURE

The stainless steel mixing tank is widely used in such industries of coatings, pharmaceuticals, building materials, chemicals, pigments, resins, food, scientific research, etc. It can be made of stainless steel 304, 304L, or 316. depending on clients’ option. And the heating and cooling devices are optional to meet different needs of production or process. The heating is available in jacket electric heating and coil heating. The equipment has features of reasonable structure design, advanced technology and durable, simple operation and convenient use. It is an ideal processing equipment with less investment, quick operation and high profit.

•The mixing tank mainly consists of tank body, cover, agitator, supporting feet, transmission device, shaft seal device, etc.

•Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel or other materials according to specific requirements.

•The tank body and the cover can be connected by flange seal or welding. Also they could be with ports for purpose of feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, safety vent, etc.

•The transmission device (a motor or a reducer) is installed on top of the cover, and it can drive the agitator inside the tank is by stirring shaft.

•The shaft seal can be used mechanical seal, packing seal or labyrinth seal as requested.

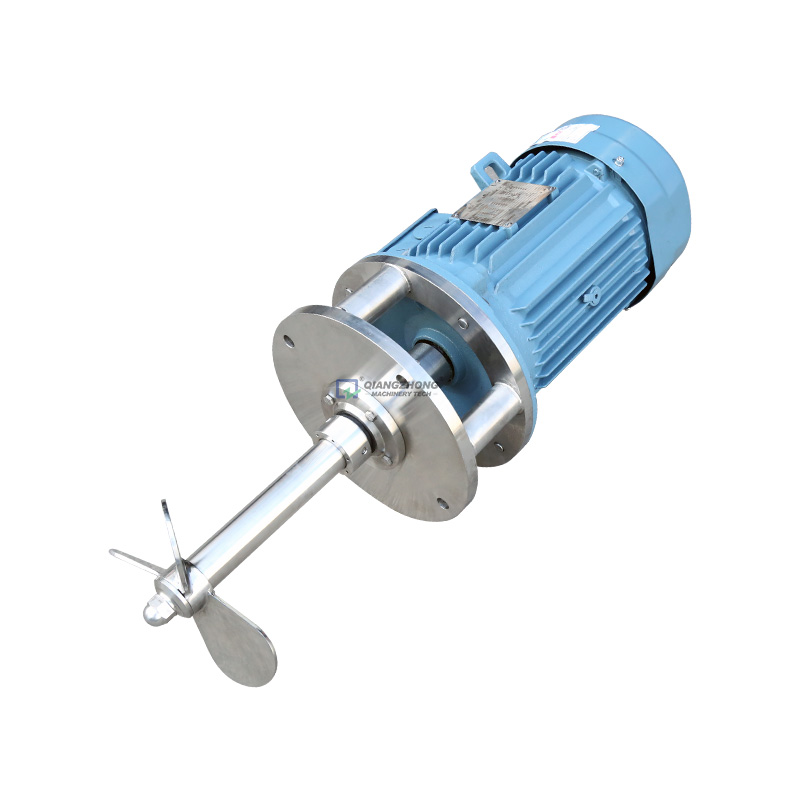

•The agitator type could be impeller, anchor, frame, spiral type, etc. according to the requirements of different application.

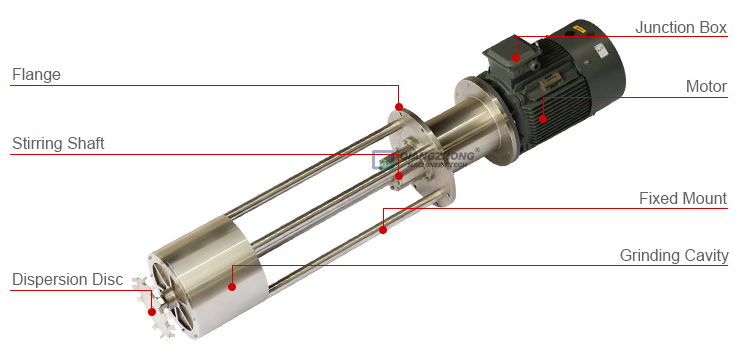

Product detail pictures:

Related Product Guide:

Cooperation

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for factory Outlets for Stainless Steel Milk Boiling Pot - Chocolate Grinding Mixing Tank – Qiangzhong, The product will supply to all over the world, such as: Pakistan, Malawi, Iraq, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

Factory making 100 Liters Fermenter - Water an...

-

Best Price on Copper Tube Heat Exchanger - Pro...

-

Hot-selling Cbd Oil Hemp Extract - JM-L Vertic...

-

Newly Arrival Pigment Mixing Machine - Stainle...

-

Low MOQ for Diamond Mirror Plastic Lipstick Tub...

-

China Factory for Lab Shear Mixer - High shear...