Factory supplied 10 Bbl Fermenter - Mobile Homogenizing Pump with Hopper – Qiangzhong Detail:

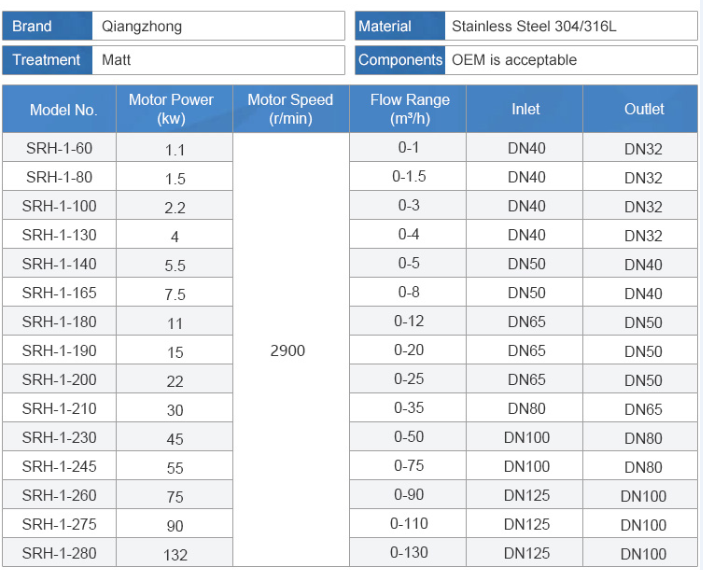

PRODUCT PARAMETERS

*The above information is for reference only and can be customized according to customer requirements. ‘This equipment can be customized according to the nature of raw materials to meet the needs of the process, such as greater viscosity, homogenization and other requirements.

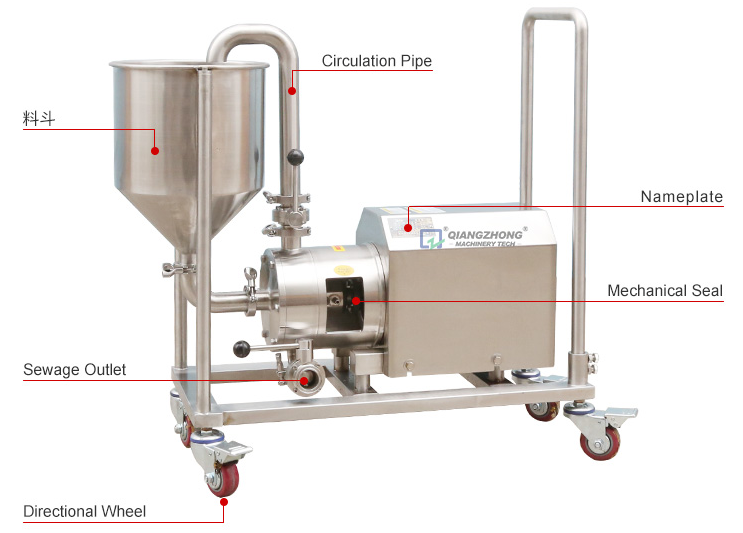

PRODUCT STRUCTURE

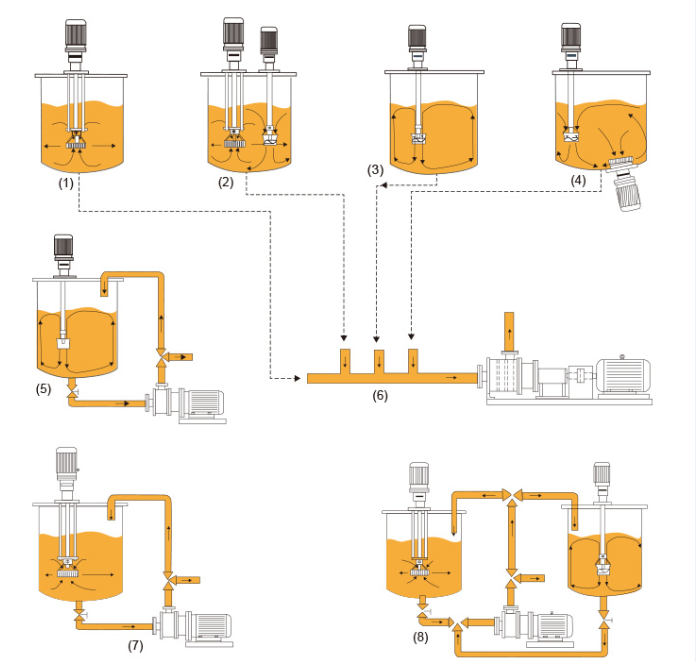

The emulsification pump (also called in-line high-shear dispersion mixer) is a high-efficient fine mixing equipment which integrates mixing, dispersion, crushing, dissolution, fine, depolymerizing, homogenization and emulsification, whose working components are mainly stator and rotator, The rotor rotates rapidly to produce centrifugal force and hydraulic force and the stator remains stationary. Through the precise combination of the rotor and the stator, a strong shear force is generated during high-speed rotation, and the material is subjected to strong shear, centrifugal extrusion, impact rupture, liquid friction, and uniform turbulence. Thus, various media such as immiscible solid phase, liquid phase, and gas phase are uniformly and finely dispersed and emulsified in an instant. After a reciprocating cycle, a stable and high-quality product is finally obtained.

The emulsification pump/in-line high-shear dispersion mixer can efficiently, quickly, and evenly distribute one or more phases into another continuous phase, while in the usual case the phases are mutually insoluble. By high shear linear velocity generated by high-speed rotation of rotor and high kinetic energy brought by high-frequency mechanical effect, the material in the narrow gap of rotor and stator is forced by a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tear and turbulence and other comprehensive effects. That makes incompatible solid phase, liquid phase and gas phase instantly homogenized, dispersed and emulsified under combined action of corresponding mature technology and proper amount of additives. Finally stable and high-quality products are available after repeated cycles of high-frequency.

Three groups of stator and rotor are installed in the working chamber of the emulsification pump. The transmission shaft in the working chamber is cantilevered. The elastic coupling connects the motor and the spindle in the bearing housing to improve the operating quality of the transmission shaft. The sealing forms are optional based on different work conditions. It is suitable for medium and large batches of on-line continuous production or recycling processing production.

PRODUCT SHOWCASE

Product detail pictures:

Related Product Guide:

Cooperation

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Factory supplied 10 Bbl Fermenter - Mobile Homogenizing Pump with Hopper – Qiangzhong, The product will supply to all over the world, such as: Atlanta, Russia, Ecuador, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

Hot Sale for Apple Cider Vinegar Making Machine...

-

Factory wholesale Bakery Cream Mixer Machine -...

-

Competitive Price for Machine Production Food -...

-

OEM Manufacturer Beverage Mixing Tanks - Manua...

-

Super Purchasing for Milk Refrigerator Tank - ...

-

Hot Selling for Milk Collection Equipment - M...