Factory Supply Heat Exchange Tube Sheet - Hydraulic-lifting Emulsification Tank – Qiangzhong Detail:

Video

Product Overview:

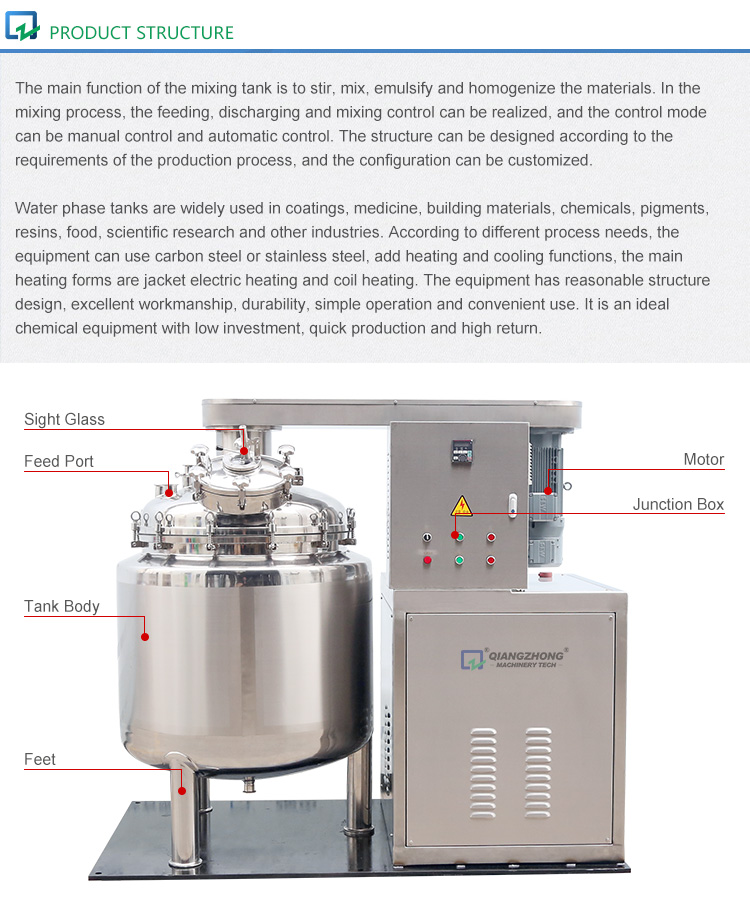

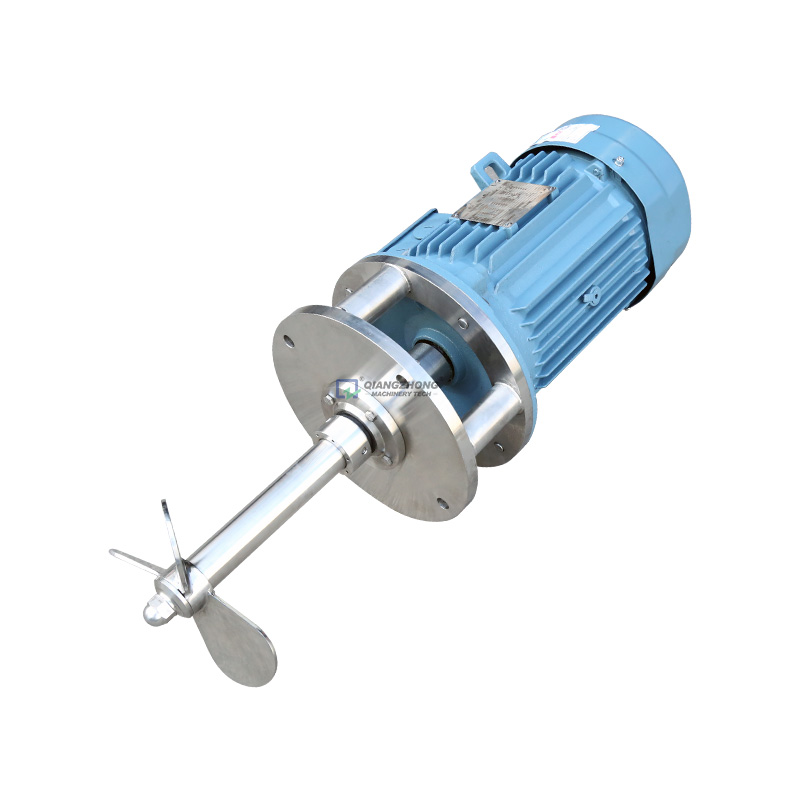

Emulsification Dispersion Tank, also known as High-speed Emulsifying tank, High-speed Dispersion Tank, suitable to continuously or cyclically produce such materials which need dispersion, emulsification, crush as cream, gelatin monoglyceride, milk, sugar, beverages, pharmaceuticals, and etc. After mixing, it can high-speed stir and disperse materials uniformly. With advantages of energy saving, corrosion resistance, strong production capacity, simple structure and convenient cleaning, it is an indispensable equipment for manufacturing dairy products, beverages and pharmaceuticals. The main configuration includes emulsifying head, air respirator, sight glass, pressure gauge, manhole, cleaning ball, caster, thermometer, level gauge and control system. Also we offer OEM solution according to clients’ requirements.

Emulsifying Tank is an advanced equipment which can mix, emulsify, homogenize, dissolve, crush materials of food, pharmaceuticals, chemicals and others. It can make one or more materials (water-soluble solid phase, liquid phase, jelly, and etc.) dissolved in another liquid phase and make them into a relatively stable emulsion. When working, work head throws materials on center of rotor at high speed, materials passing through tooth space of stator, and finally achieve the purpose of emulsification by power of shear, collision and smash between rotor and stator. It’s widely used for processing oil, powder, sugar and so on. Also it can emulsify and mix raw materials of some coatings, paint, and especially some difficult-soluble colloidal additives, such as CMC, xanthan gum.

Equipment Features:

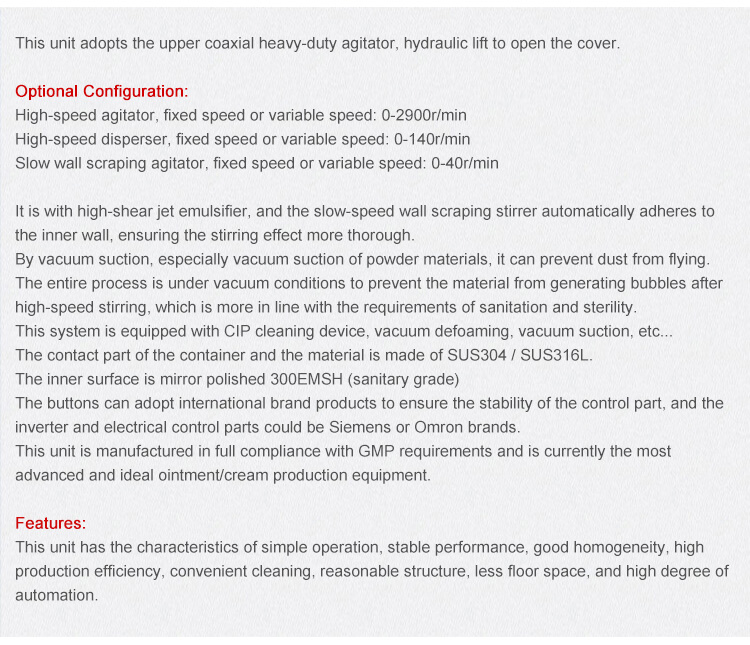

This series of High-shear Emulsifying Tank is designed for mass production and with structure of claw bite and two-way suction to avoid dead space and swirl due to that partial material is difficult to inhale. Strong shear power can improve production efficiency and quality of dispersion and emulsification. The equipment efficiently, rapidly and evenly distributes one or more phases into another continuous phase, while in general the phases are incompatible. By high shear linear velocity generated by high-speed rotation of rotor and high kinetic energy brought by high-frequency mechanical effect, incompatible solid phase, liquid phase and gas phase can be instantly homogenized, dispersed and emulsified under combined action of corresponding mature technology and proper amount of additives. Finally stable and high-quality products are available after repeated cycles of high-frequency.

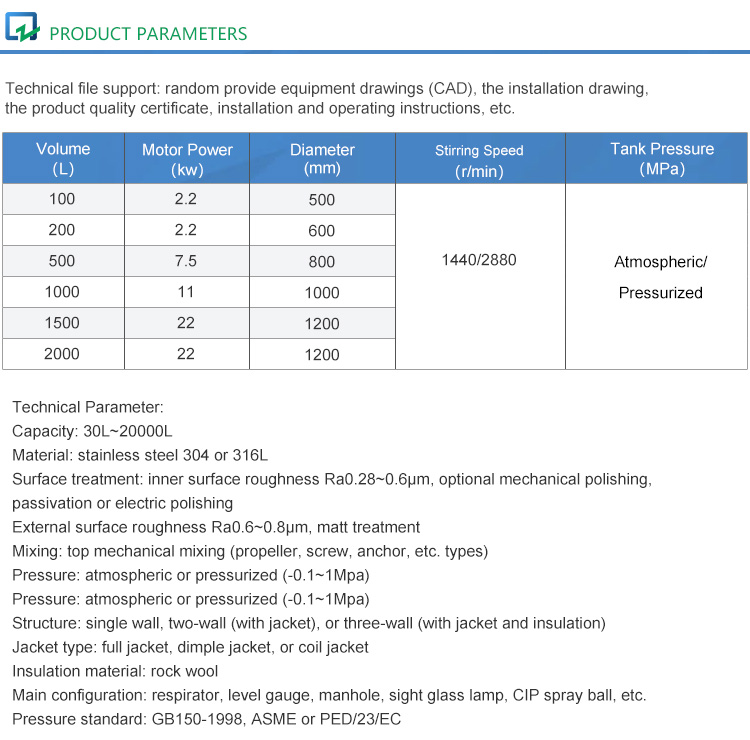

◎Mixing power is standard configuration in the chart. Any other requests of clients, please confirm with us.

◎Jacket pressure is atmospheric pressure, we could also customize it according to customer requirements.

◎For selection of Emulsification Tank, please provide information include: nature of material, pressure, parameter of temperature, special requirements, and etc.

Working principle:

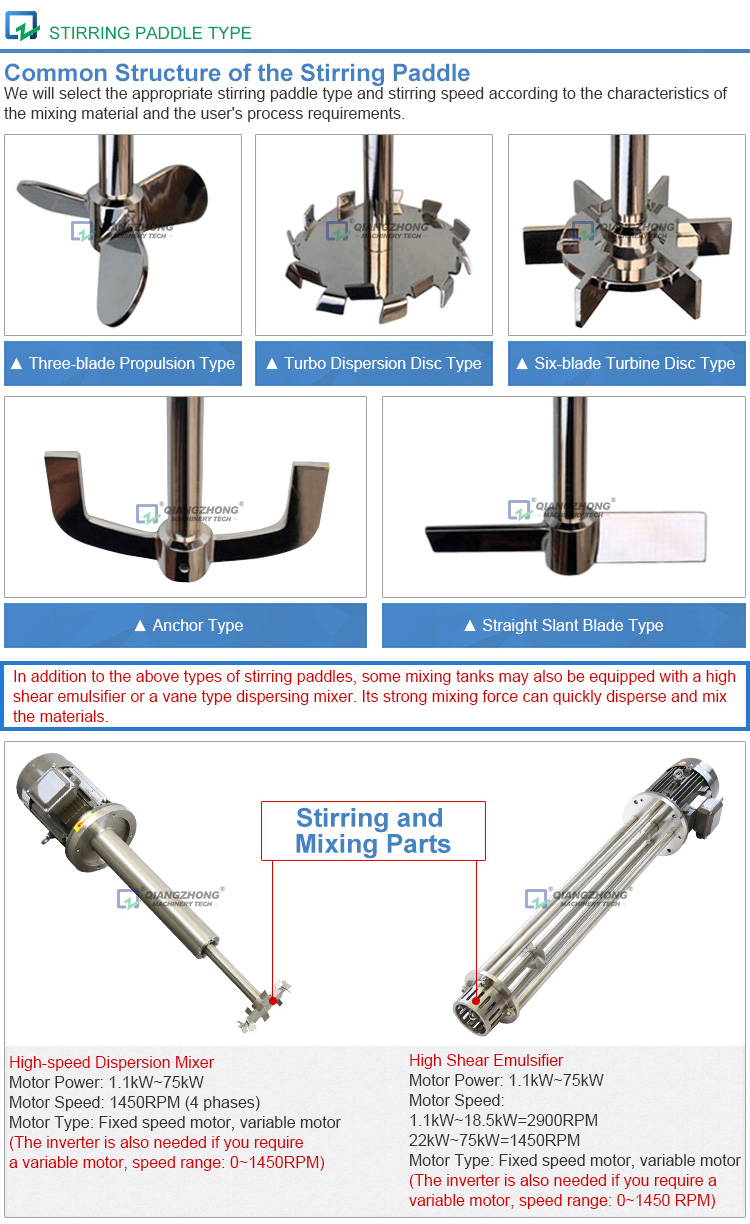

Centrifugal high-speed emulsifying head can produce huge rotary suction force at work, rotate materials just above rotor to suck it down, and then throw it to stator at high speed. After high-speed shearing, collision and crushing between stator and rotor, materials collect and spray out from outlet. At the same time, swirling force of vortex baffle at the bottom of tank transforms into a up-and-down tumbling force, so that materials in the tank are mixed uniformly to prevent powder from agglomerating in liquid surface to achieve the purpose of hydration emulsification.

Centrifugal high-speed emulsifying head can produce huge rotary suction force at work, rotate materials just above rotor to suck it down, and then throw it to stator at high speed. After high-speed shearing, collision and crushing between stator and rotor, materials collect and spray out from outlet. Pipeline high-shear emulsifier is equipped with 1-3 groups of dual occlusion multi-layer stators and rotors in the narrow cavity. Rotors rotate at high speed under driving of motor to generate strong axial suction, and materials are sucked into the cavity, recycling process materials. The materials are dispersed, sheared, emulsified in the shortest possible time, and finally we get fine and long-term stable products. High-speed emulsifier can efficiently, rapidly and evenly distributes one or more phases into another continuous phase, while in general the phases are incompatible. By high shear linear velocity generated by high-speed rotation of rotor and high kinetic energy brought by high-frequency mechanical effect, materials in the narrow gap of rotor and stator are forced by a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tear and turbulence and other comprehensive effects. That makes incompatible solid phase, liquid phase and gas phase instantly homogenized, dispersed and emulsified under combined action of corresponding mature technology and proper amount of additives. Finally stable and high-quality products are available after repeated cycles of high-frequency.

Product detail pictures:

Related Product Guide:

Cooperation

Persisting in "High good quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for Factory Supply Heat Exchange Tube Sheet - Hydraulic-lifting Emulsification Tank – Qiangzhong, The product will supply to all over the world, such as: France, Hyderabad, El Salvador, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Best-Selling Home Brewing Beer - JM-F Split Co...

-

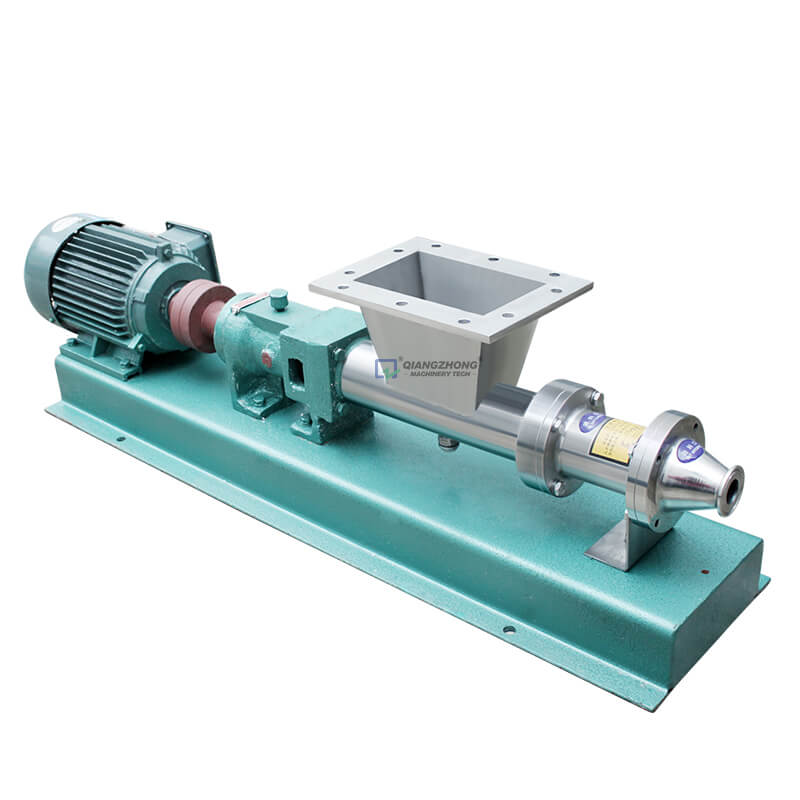

Popular Design for Pump Emulsifier - Single Sc...

-

Quality Inspection for Beverage Mixer - Electr...

-

Hot Sale for Fermenter Tank 500l - Vacuum Stir...

-

Reliable Supplier Industrial Pepper Grinding Ma...

-

OEM manufacturer Wort Pump - Sanitary Negative...