Factory Supply Rubber Hose Production Machine - Plate Filter – Qiangzhong Detail:

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine manufactured after innovation and improvement. The product has a novel appearance and practicality. It can fit various kinds of filter materials such as filter cloth, filter paper board, filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

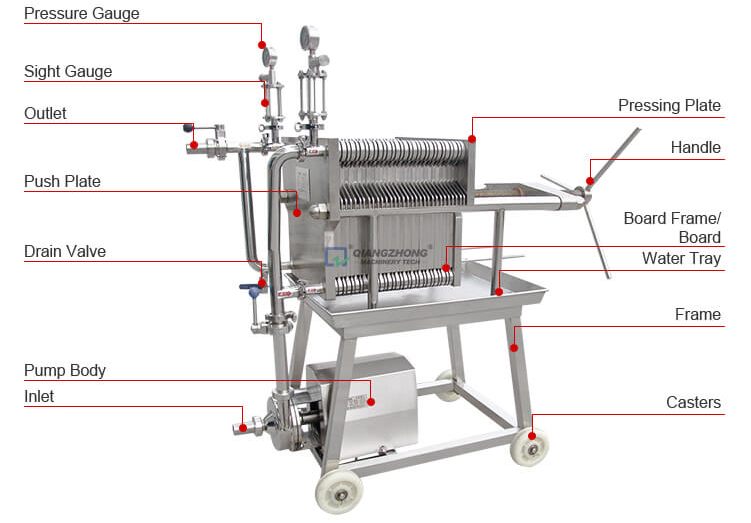

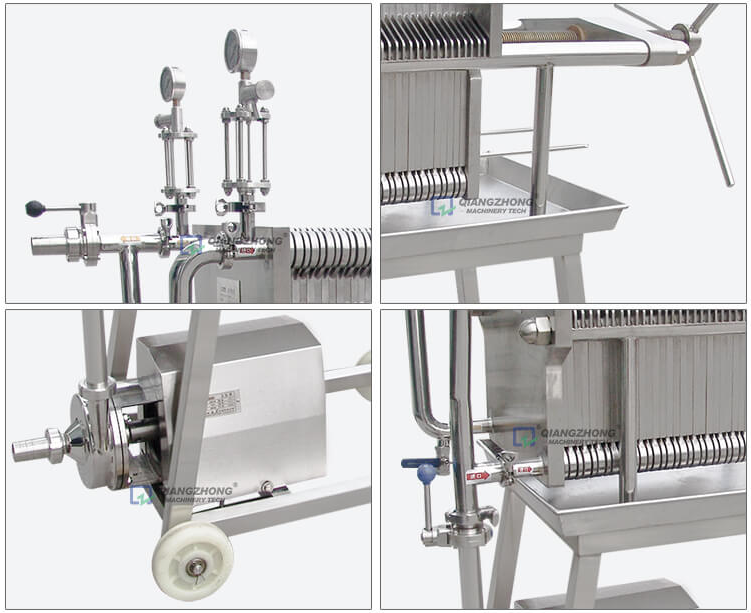

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during filtration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter, but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop.

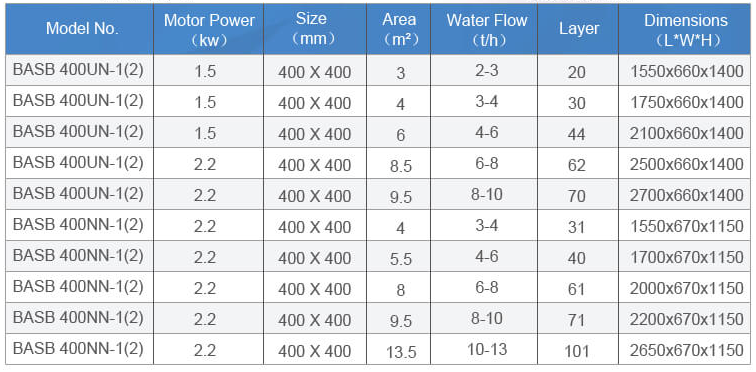

Product Parameters

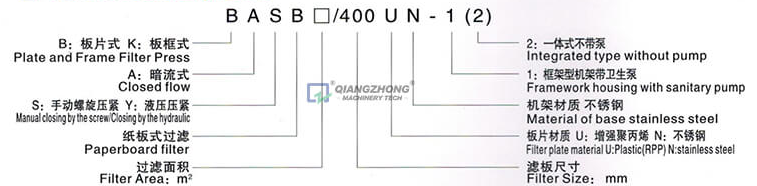

Model Designation

Product Structure

Four comers of each filter plate of the frame filter have four liquid-passing corner holes, and only the two vertical comer holes are communicated with the inside, and the filter plate and the filter frame are alternately arranged (the filter plate is double-sided hole plate, filter frame is non-porous plate). During filtration, media is fed through two liquid-passage holes on one side of the filter frame. After passing through the filter layer (filter media), the clear liquid is discharged from the two liquid outlet comer holes on the filter plate side.

Product Introduction

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine manufactured after innovation and improvement. The product has a novel appearance and practicality. It can fit various kinds of filter materials such as filter cloth, filter paper board, filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during filtration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter, but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop.

Film filter:

The film filter material made of mixed fibers meets the quality standards, and its product surface is smooth, light and thin, with high porosity and uniform pore structure, so it has the characteristics of high flow velocity and low adsorption.

This product is suitable for the pharmaceutical industry, biological products, electronics industry, brewing, watches and other industries, and it can filter medical oil, lubrication oil, fuel oil, etc., filter bacteria and particles. It is also used for scientific research experiments, laboratory, etc. Generally it can remove 0.65um particles, bacteria below 0.45um.

Product Showcase

Use And Maintenance Instructions

• When installing or replacing the filter material, it should be tightly attached to the silicone rubber ring, the position must be moderately flat, and then press the moving plate to prevent leakage.

• If you want to stop the equipment, please first close the inlet ball valve, and then cut off the power to prevent the liquid back against the impact and destroy the filter membrane.

• When maintaining the filter, first wash it with 3%-5% sodium bicarbonate solution, rinse it again with clean water and pure water, finally sterilize, and check the PH value to ensure that it reaches the allowable range.

Product detail pictures:

Related Product Guide:

Cooperation

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Factory Supply Rubber Hose Production Machine - Plate Filter – Qiangzhong, The product will supply to all over the world, such as: Nairobi, Colombia, Jordan, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

China Supplier Lab Vortex Mixer - Shear and Em...

-

factory customized Equipment Used For Emulsion ...

-

Super Purchasing for Closed Loop Extractor Syst...

-

OEM/ODM Manufacturer Paint Tank - Sanitary Pne...

-

Renewable Design for Dry Screw Vacuum Pump - S...

-

Europe style for Pressure Tank For Water Pump -...