Factory wholesale Extraction Vessel - Hot and cold mixing tank – Qiangzhong Detail:

Heating and Cooling Mixing Tank

We specialize in manufacturing food and medical equipment, and know you better! Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries.

PRODUCT PARAMETERS

|

Capacity (L) |

Motor Power |

Jacket Pressure |

Inner-wall Thickness |

Outer Package Thickness |

Jacket Thicknes |

Insulation |

|

100 |

0.75(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

Rock Wool Insulation

|

|

200 |

075(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

300 |

0.75(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

500 |

0.75(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

600 |

0.75(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

800 |

0.75(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

1000 |

1.1 (kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

1500 |

1.1 (kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

|

|

2000 |

L5(kw) |

0.09(Mpa) |

3(mm) |

0.6(mm) |

3(mm) |

Steam Heating and Cooling Tank(with cover and mixer) SS304 Specifications

|

Nominal Capacity(L) |

300 |

500 |

1000 |

2000 |

3000 |

5000 |

6000 |

8000 |

10000 |

|

Internal Tank Diameter(mm) |

800 |

900 |

1100 |

1400 |

1600 |

1800 |

1900 |

2000 |

2100 |

|

Mixer Power(kw) |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3.0 |

4.0 |

5.5 |

5.5 |

|

Heat Exchange Area(rr?) |

1.7 |

3.0 |

45 |

7,5 |

10 |

13 |

15 |

18 |

21 |

|

Mixer Speed(r/min) |

Optional Speed: 17RPM, 32RPM, 48RPM, 60RPM, 82RPM, 127RPM, 155RPM, or stepless speed, frequency control |

||||||||

|

Working Pressure(Mpa) |

Jacket Pressure: 0.08 ~ 0.3MPa, inner tank pressure: atmospheric pressure |

||||||||

|

Working Temperature(°C) |

Jacket Temperature: <138°C, inner tank temperature: <100 °C |

||||||||

|

Material |

Materials: Inner Tank: stainless steel SUS304/SUS316L; Jacket: SUS304/Q235-B; Outer Tank: SUS304 |

||||||||

|

Type |

According to design pressure and characteristics of medium, tank could be classified as atmospheric pressure tank and first-type pressure tank |

||||||||

PRODUCT STRUCTURE

1.Power of stirring motor in the chart is for reference. Configurations of power of stirring motor, stirring speed and stirring paddle type depend on nature of processing materials.

2.Other requirements not listed in the diagram, such as volume, can be customized according to user requirements.

3 To determine best suitable batching tank, please provide such information including: nature of material, working pressure, working temperature, working conditions, and etc.

Product detail pictures:

Related Product Guide:

Cooperation

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Factory wholesale Extraction Vessel - Hot and cold mixing tank – Qiangzhong, The product will supply to all over the world, such as: Angola, Czech Republic, Lahore, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

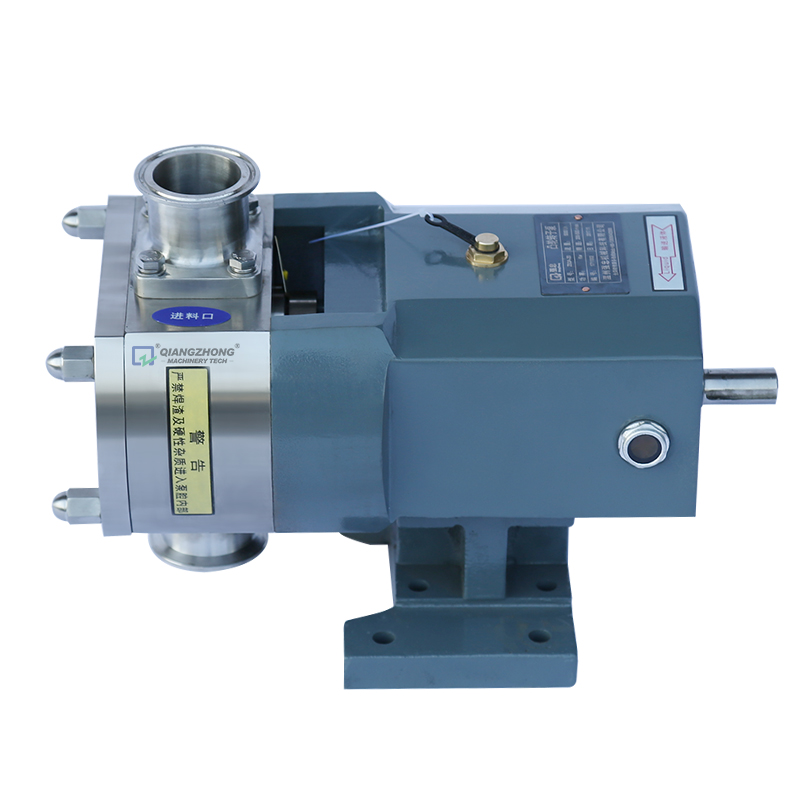

OEM/ODM China Polymer Transfer Pump - Rectangl...

-

2021 China New Design Hot Melt Gear Pump - San...

-

PriceList for Ice Cream Machine Pump - Self-pr...

-

OEM Customized Pesticide Tank - Cam Rotor Pump...

-

Hot sale Butter Homogenizer - Multi-bag Filter...

-

Competitive Price for Caramel Candy Making Mach...