Factory wholesale High Shear Emulsification Pump - Mobile Lifting Mixer – Qiangzhong Detail:

Video

Suitable for stirring / emulsifying / homogenizing / mixing / dispersing processes

Low noise, high efficiency, smooth operation, no dead ends. Material 100% pass through the work chamber, no residue, large capacity. It’s suitable for industrial continuous online production, processing a wide range of viscosity.

* The flow range in the table refers to the data measured when the medium is “water”.

* If the viscosity or consistency of the medium is high, it is recommended to use it with an in-line high shear homogenizer.

* If the machine is to be used at high temperature, high pressure flammable, explosive, corrosive and other working conditions, please provide relevant accurate parameters for correct selection or customization.

*Any modification that does not change the basic structure and performance won’t be notified in advance.

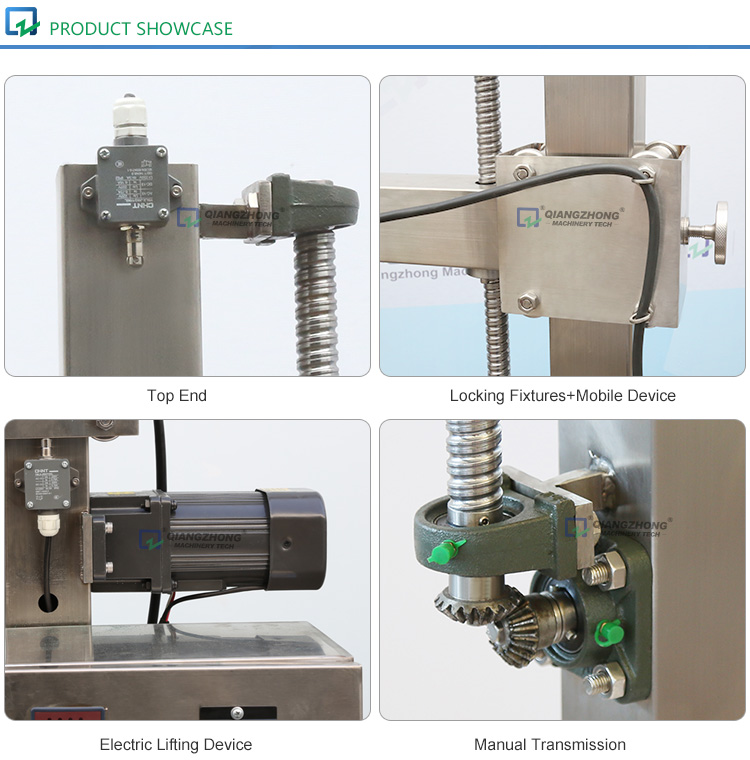

Bracket Device

High-precision stainless steel, corrosion-resistant, durable, beautiful and generous.

Paddle Mixer

Mixer shaft can be horizontal or oblique into the slot, leading to the asymmetric circulation loop of liquid flow, increasing turbulence, preventing depression of the liquid level.

Solid Shaft

Pure stainless steel shaft, providing super power, safe production.

Safe Motor Unit

Body rust coating and water tray structure to improve the safety of the motor, and the motor directly drives the grinding head to rotate, saving grinding time.

Product Structure

The propeller mixer has a simple structure, easy to manufacture. It has a small shearing effect and a good cycle performance, and it belongs to a circulating type mixer. The mixer consists of a motor, mechanical seal, plugging device, a mixing shaft, a mixer, etc. It is suitable for applications with low viscosity and high flow. It is with a small mixing power to obtain a better mixing effect through high speed rotation of the paddle, mainly used for liquid-liquid system mixing with a good temperature uniformity and also the low concentration of solid-liquid system to prevent sedimentation, etc.

Product Introduction

The propeller mixer is commonly used in low viscosity fluid. The standard propeller type is a three-lobed blade with a pitch equal to the diameter of the paddle. During mixing, the fluid is sucked from above the blade and discharged downwards in a cylindrical spiral shape. The fluid returns to the bottom of the tank and then returns to the top of the blade along the wall to form an axial flow. The degree of turbulence of the fluid during mixing by the propeller mixer is not high, but the amount of circulation is large. When the baffle is installed in the tank, the mixing shaft is installed eccentrically or the mixer is inclined, the vortex formation can be prevented. The diameter of the propeller shoulder naga is small, the ratio of the diameter of the blade to the inner diameter of the tank is generally 0.1 to 0.3, the speed of the tip end line is 7 to 10 m/s, the maximum is 15m/s.

Product Features

1. Compact structure, stable operation, few transmission links, high mechanical efficiency

2. It can reach a certain mixing intensity in the required time, meeting the requirements of fast, uniform and full mixing, small loss. And it can adapt to the change of water volume to be suitable for the mixing of various medium capacities.

3. No need to discharge materials when replacing mechanical seals.

4. Small size, large processing capacity, low energy consumption, low noise.

5. Low cost of Installation, operation and maintenance.

Product detail pictures:

Related Product Guide:

Cooperation

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for Factory wholesale High Shear Emulsification Pump - Mobile Lifting Mixer – Qiangzhong, The product will supply to all over the world, such as: South Korea, kazan, San Diego, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

-

Wholesale Stainless Mixer - Fixed bracket disp...

-

100% Original Stand Mixer Electric - High Shea...

-

Factory Price For Tomato Paste Machine Making -...

-

Good User Reputation for Food Mixing Tank - JM...

-

Free sample for Production Of Banana Jam - Top...

-

Special Design for Laboratory Vacuum Mixer - M...