Heating and Cooling Tank

PRODUCT STRUCTURE

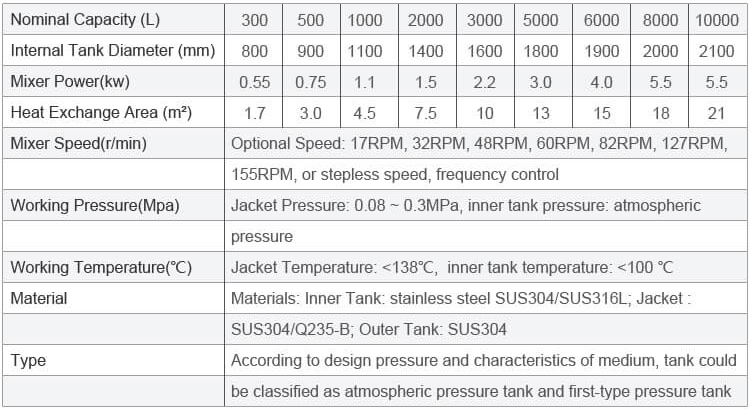

Steam Heating and Cooling Tank(with cover and mixer) SS304 Specifications

Optional Speed: 17RPM, 32RPM, 48RPM, 60RPM, 82RPM, 127RPM, 155RPM, or stepless speed, frequency control

Jacket Pressure: 0.08 ~ 0.3MPa, inner tank pressure: atmospheric pressure

Jacket Temperature: <138℃, inner tank temperature:

Materials: Inner Tank: stainless steel SUS304/SUS316L; Jacket : SUS304/Q235-B; Outer Tank: SUS304

According to design pressure and characteristics of medium, tank could be classified as atmospheric pressure tank and first-type pressure tank

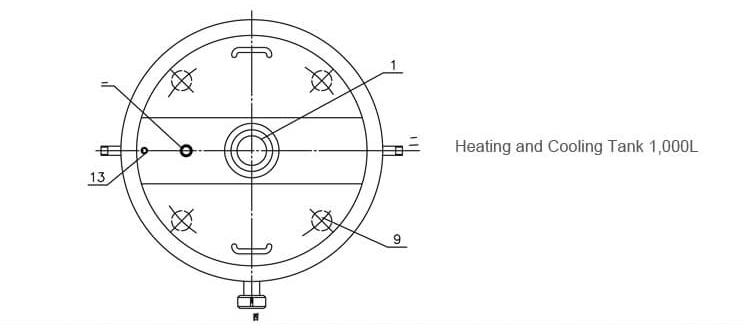

Heating and Cooling Tank 1,000L

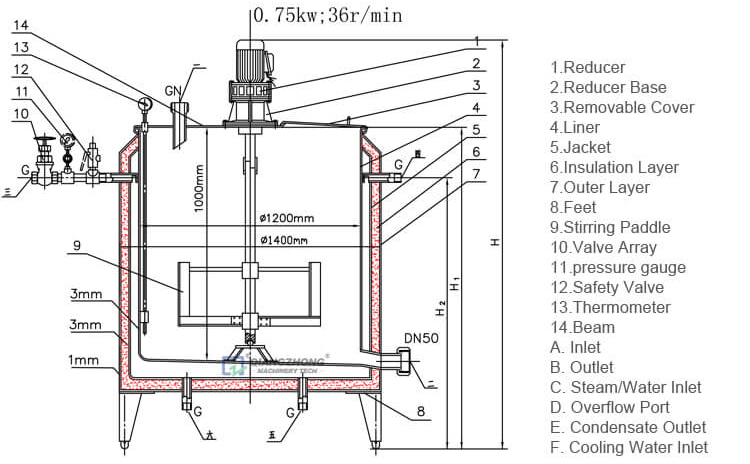

| 1.Reducer | A. Inlet |

| 2.Reducer Base | B. Outlet |

| 3.Removable Cover | C. Steam/Water Inlet |

| 4.Liner | D. Overflow Port |

| 5.Jacket | E. Condensate Outlet |

| 6.Insulation Layer | F. Cooling Water Inlet |

| 7.Outer Layer | |

| 8.Feet | |

| 9.Stirring Paddle | |

| 10.Valve Array | |

| 11.pressure gauge | |

| 12.Safety Valve | |

| 13.Thermometer | |

| 14.Beam |

Note:

1. Power of stirring motor in the chart is for reference. Configurations of power of stirring motor, stirring speed and stirring paddle type depend on nature of processing materials.

2. Other requirements not listed in the diagram, such as volume, can be customized according to user requirements.

3 To determine best suitable batching tank, please provide such information including: nature of material, working pressure, working temperature, working conditions, and etc.

4.Attached technical documents: drawings (CAD) of structure and dimension, installation drawings, quality certificate, manual of installation and operation.

PRODUCT SHOWCASE