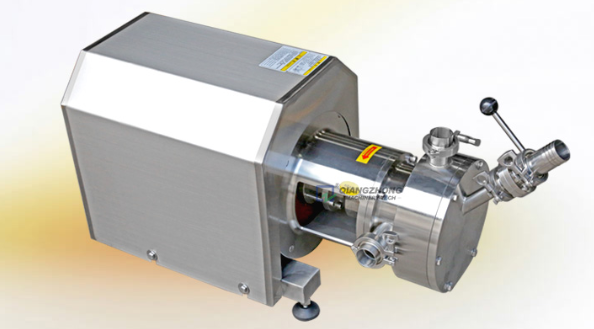

High definition Emulsification Machine - Powder Liquid Mixer – Qiangzhong Detail:

PRODUCT PARAMETERS

| Model No. |

Motor Power (KW) |

Speed (RPM) |

Flow Rate (m3/h) |

Outlet Pressure (Bar) |

Suction Capacity (kg/s) |

|

SRH-C-120 |

5-575 |

2900 |

0-10 |

1.5 |

0-500 |

|

SRH-C-140 |

11/15 |

2900 |

0-20 |

2 |

0-1000 |

|

SRH-C-165 |

22/30 |

2900 |

0-30 |

2.5 |

0-2000 |

|

SRH-C-200 |

37/45 |

2900 |

0-50 |

3 |

0-3000 |

|

SRH-C-260 |

55/75 |

2900 |

0-70 |

4 |

0-4000 |

Notice:

* The flow range data in the above table is test result based on water as test media.

* The suction capacity depends on the characteristics of the powder itself (such as particle size, swellability, fluidity, etc.). If it cannot be confirmed, please provide samples or select by experimental data;

* If there are special working conditions, please provide detailed and accurate technical parameters and process requirements for our professional engineers to provide corresponding solutions.

The data in this form is subject to change without prior notice. The correct parameters are subject to the actual product provided.

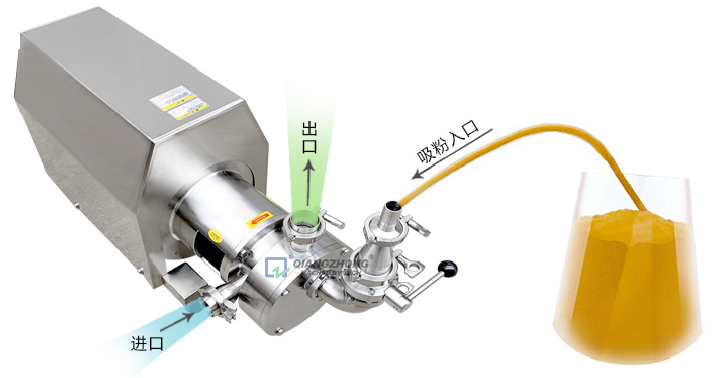

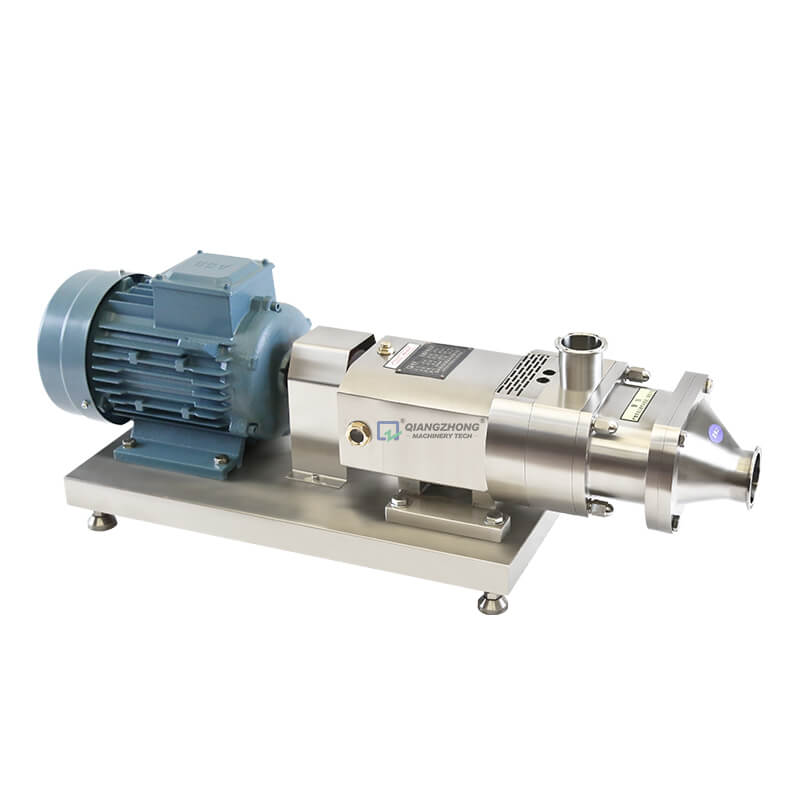

PRODUCT DESCRIPTION

All the process steps can be completed with only one device: after the powder suction tube is fed, it can quickly complete the powdering, feeding, wetting, and dispersion without agglomeration. Not only can the powder be wetted, but it can also be dispersed into the liquid in a vacuum environment to avoid a large amount of air entering. It can avoid material agglomeration, achieve good reaction effect, higher material utilization rate and better product quality. The device’s high module integration saves a lot of piping and process steps, minimizing production costs.

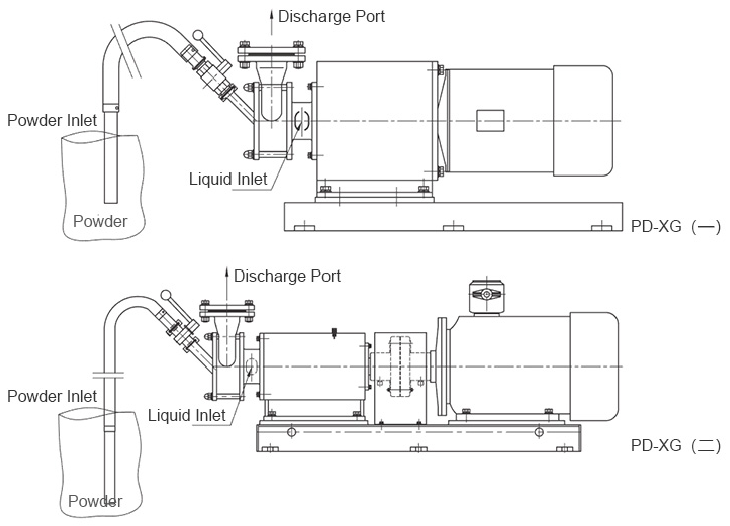

Working Principle

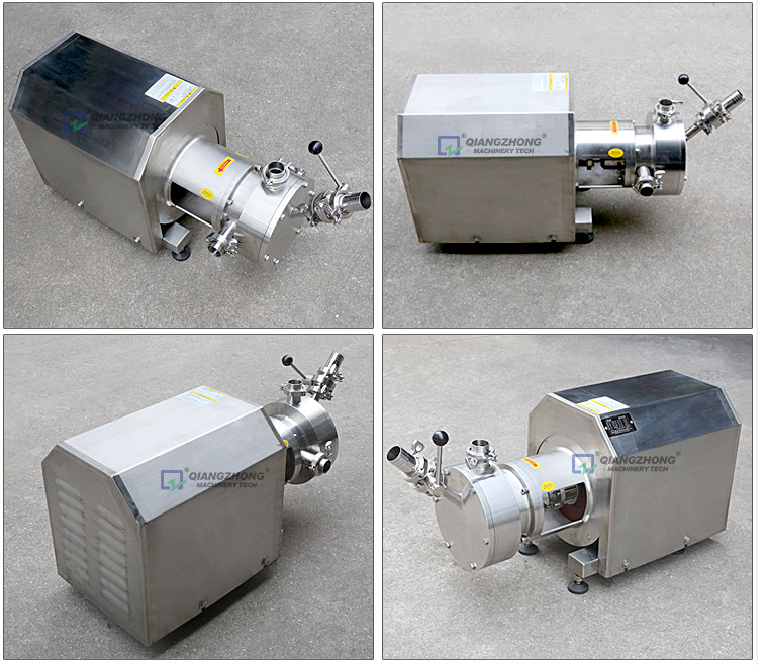

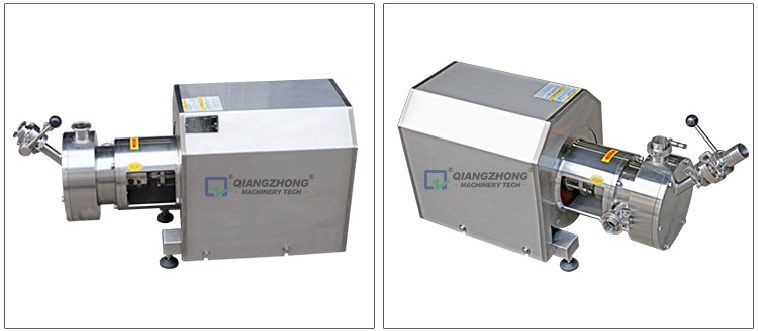

Product detail pictures:

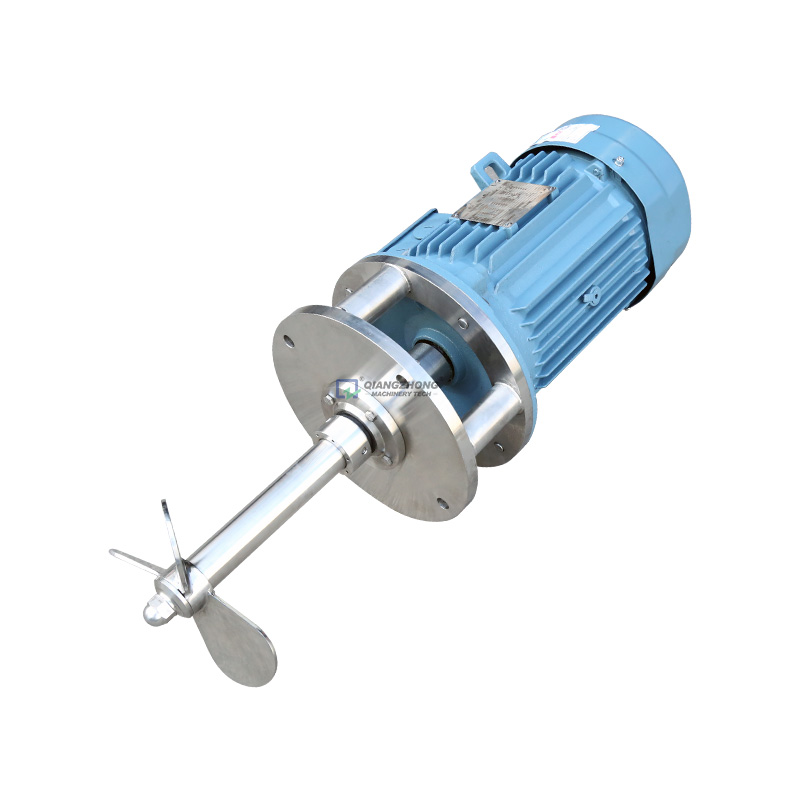

Related Product Guide:

Cooperation

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for High definition Emulsification Machine - Powder Liquid Mixer – Qiangzhong, The product will supply to all over the world, such as: Hyderabad, Mozambique, Nepal, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.