High Quality for Peanut Butter Production Line - Vacuum Stirring Emulsion Tank – Qiangzhong Detail:

Structure and Work Flow

The external circulation homogenization system is the core of the system. It integrates inhalation, transport, dispersion, and CIP online cleaning. The two-stage pump design allows the homogenization system to provide not only the power to mix the material, but also the powerful pumping capacity and the ability to deliver highly viscous materials. It allows the aqueous phase and the oil phase to be emulsified directly in the homogenization system, and then pumped to the reactor for agitation, thus avoiding the defects caused by the conventional process.

This is a very efficient system that combines high cycle throughput, uniformity of production material particle size and high efficiency emulsification. Solids and liquids can be added directly to the emulsification head and quickly and completely emulsified and dispersed to avoid agglomeration. In the CIP cleaning process, the system can be used as a transfer pump to provide high pressure cleaning fluid for rotating spray balls.

1 .The emulsification and dispersion phases are added directly to the working head.

2. The modular design of the tie rod is convenient for maintenance and disassembly.

3. Material circulation, CIP cleaning, no additional pumps are required for discharge.

4. Free choice of whether the material will pass through the emulsification chamber.

5. Better processing results, shorter processing time.

The core emulsification system can be combined with different hoppers, pretreatment reactors and discharge buffer tanks depending on the production needs. According to the material, different heating and cooling devices can be added. Even the circulation line can directly pass steam to heat the material. More efficient is our constant pursuit.

This system electronic control unit can be configured with simple button control or a PLC touch screen system with recipe control, depending on the customer’s choice. Manual or fully automatic machines are also available upon request.

Compared with the same type of equipment abroad, our automated system can not only meet the customer’s performance requirements (can provide simple system experiments), but also has great advantages in terms of price, delivery time and after-sales service.

PRODUCT SHOWCASE

Product detail pictures:

Related Product Guide:

Cooperation

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for High Quality for Peanut Butter Production Line - Vacuum Stirring Emulsion Tank – Qiangzhong, The product will supply to all over the world, such as: Sao Paulo, Malaysia, Honduras, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one's detailed specifications.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Factory source Beer Production Machinery Line -...

-

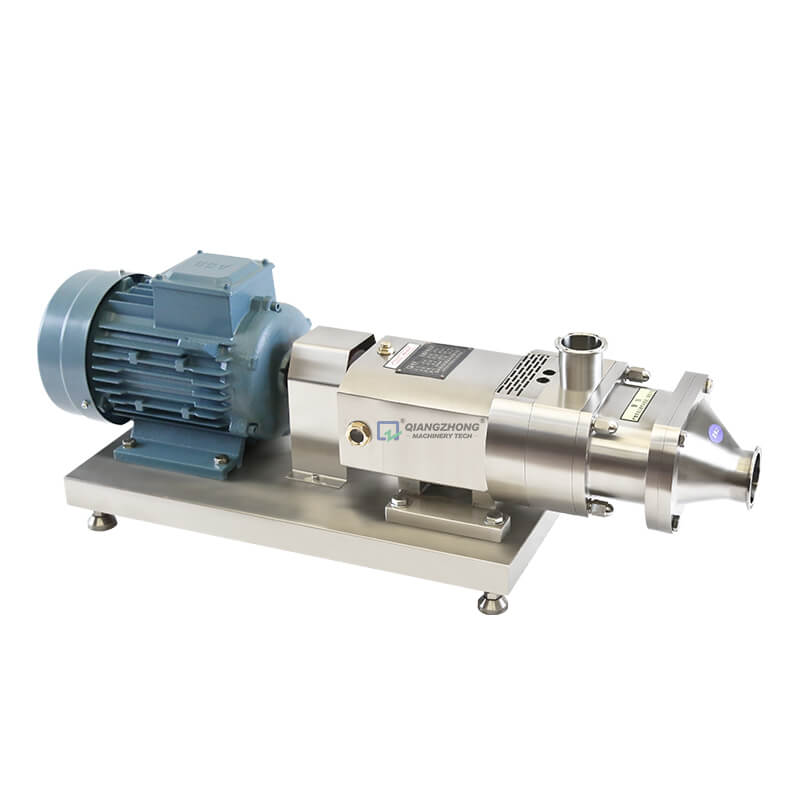

Top Suppliers Stainless Steel Rotor Pumps - Sa...

-

Factory supplied Stainless Steel Wine Storage T...

-

OEM Supply Laboratory Colloid Mill - Sanitary ...

-

OEM/ODM China Make Ice Cream Machine - Twin Sc...

-

China Manufacturer for Big Size Rice Cooker - ...