Leading Manufacturer for Beverage Mixer Tank - Powder Liquid Mixer – Qiangzhong Detail:

PRODUCT PARAMETERS

| Model No. |

Motor Power (KW) |

Speed (RPM) |

Flow Rate (m3/h) |

Outlet Pressure (Bar) |

Suction Capacity (kg/s) |

|

SRH-C-120 |

5-575 |

2900 |

0-10 |

1.5 |

0-500 |

|

SRH-C-140 |

11/15 |

2900 |

0-20 |

2 |

0-1000 |

|

SRH-C-165 |

22/30 |

2900 |

0-30 |

2.5 |

0-2000 |

|

SRH-C-200 |

37/45 |

2900 |

0-50 |

3 |

0-3000 |

|

SRH-C-260 |

55/75 |

2900 |

0-70 |

4 |

0-4000 |

Notice:

* The flow range data in the above table is test result based on water as test media.

* The suction capacity depends on the characteristics of the powder itself (such as particle size, swellability, fluidity, etc.). If it cannot be confirmed, please provide samples or select by experimental data;

* If there are special working conditions, please provide detailed and accurate technical parameters and process requirements for our professional engineers to provide corresponding solutions.

The data in this form is subject to change without prior notice. The correct parameters are subject to the actual product provided.

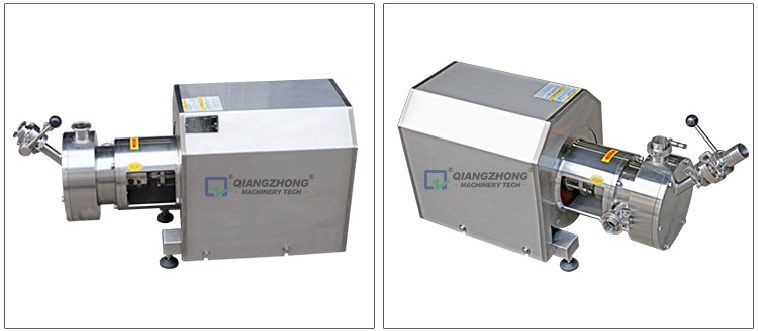

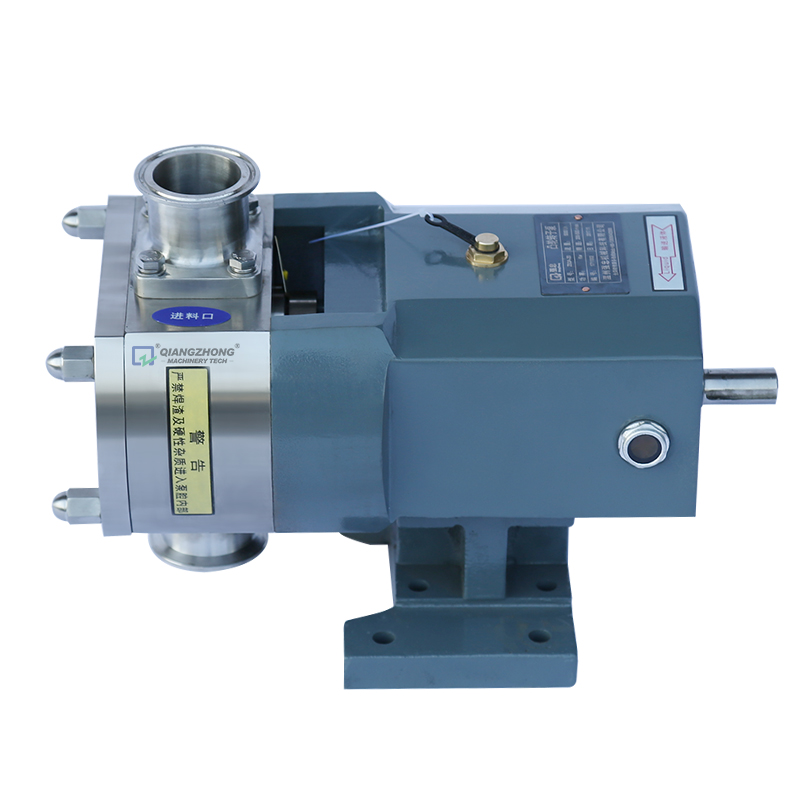

PRODUCT DESCRIPTION

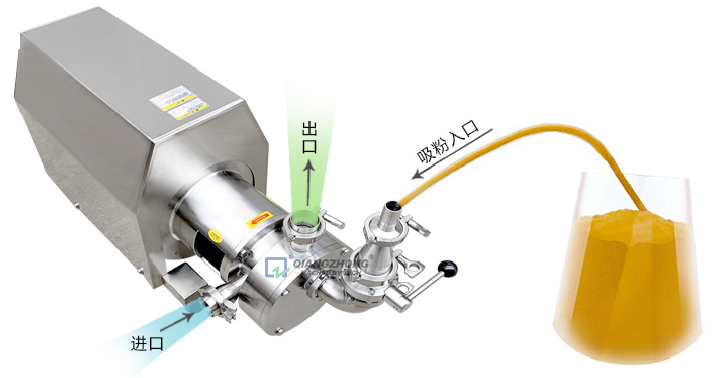

All the process steps can be completed with only one device: after the powder suction tube is fed, it can quickly complete the powdering, feeding, wetting, and dispersion without agglomeration. Not only can the powder be wetted, but it can also be dispersed into the liquid in a vacuum environment to avoid a large amount of air entering. It can avoid material agglomeration, achieve good reaction effect, higher material utilization rate and better product quality. The device’s high module integration saves a lot of piping and process steps, minimizing production costs.

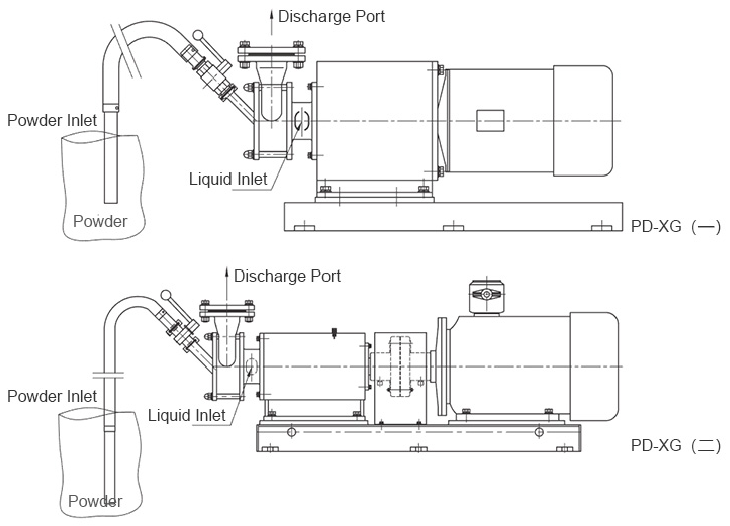

Working Principle

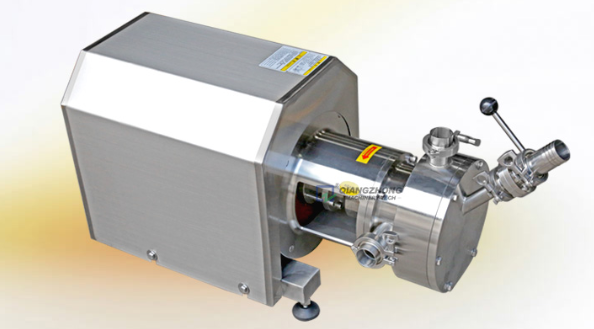

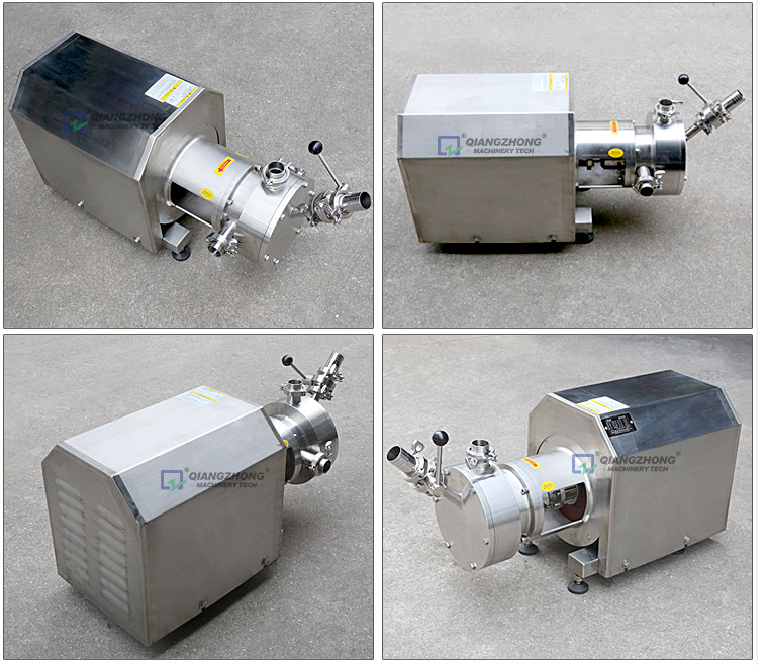

Product detail pictures:

Related Product Guide:

Cooperation

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for Leading Manufacturer for Beverage Mixer Tank - Powder Liquid Mixer – Qiangzhong, The product will supply to all over the world, such as: Nairobi, Accra, Vietnam, Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

-

Factory Free sample Coffee Grinder Electric - ...

-

OEM manufacturer Liquid Blender - Cam Rotor Pu...

-

100% Original Factory High Pressure Diaphragm W...

-

New Delivery for Vinegar Production Line - JM-...

-

Europe style for Electric Brewing System - JM-...

-

Massive Selection for Fermenter 100 L - Mobile...