Leading Manufacturer for Heated Planetary Mixer - High Shear Emulsifier Type II – Qiangzhong Detail:

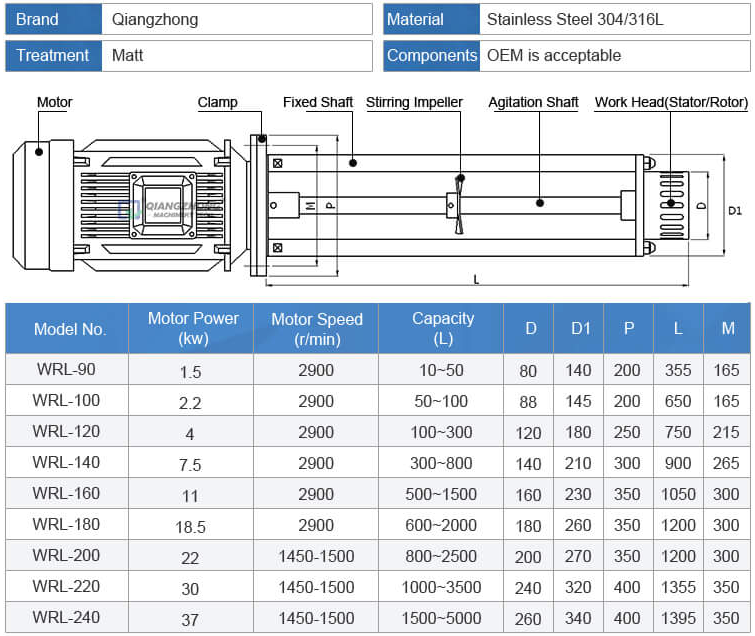

Product Parameters

*The above information is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to customer’s materials to meet the needs of the process, such as requiring greater viscosity, enhanced homogenization function, heat sensitive materials and other requirements.

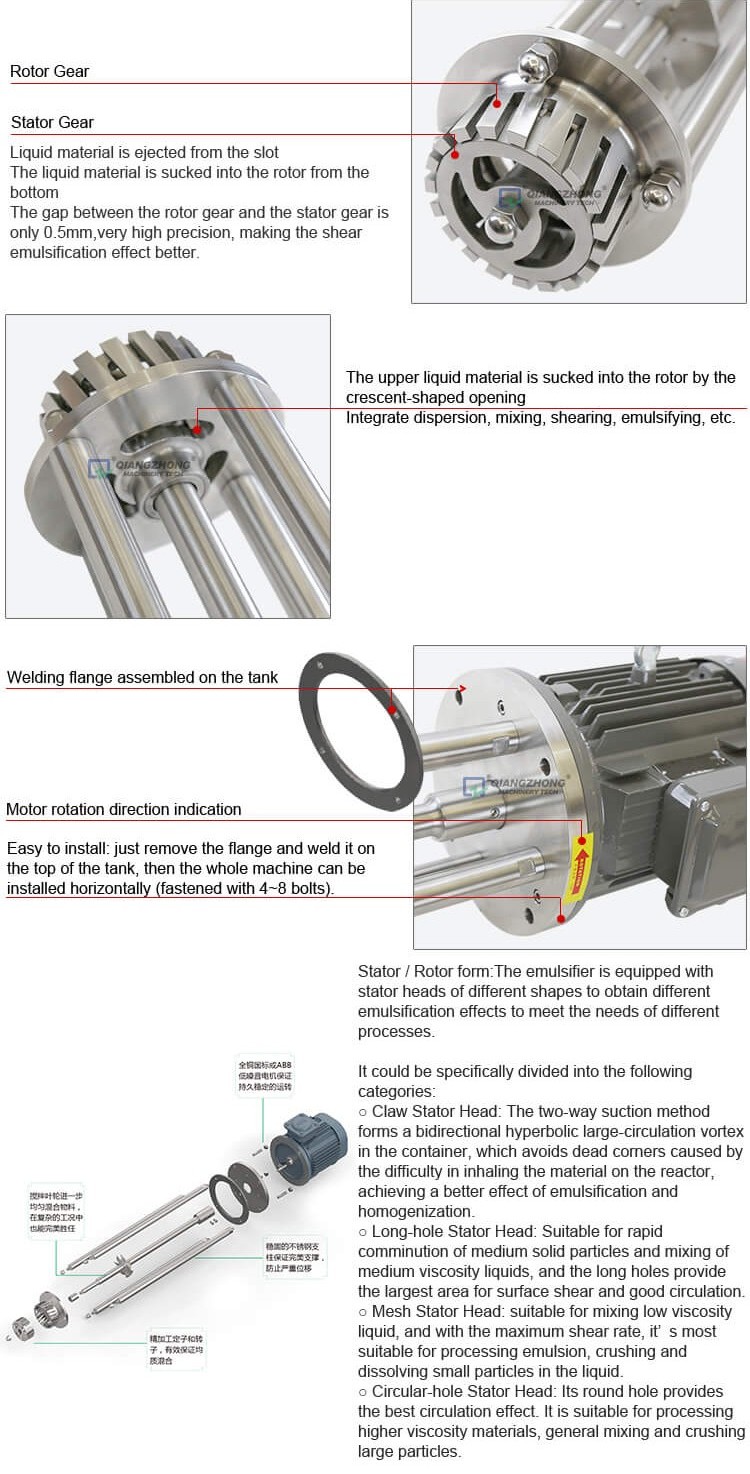

PRODUCT STRUCTURE

The emulsifier works by the high-speed rotor gear and the stator gear to fully and rapidly emulsify, homogenize and disperse the mixture in the vessel. It is widely used in food, dairy, beverage, bio-pharmaceutical, fine chemicals, pigments and other industries to improve production efficiency and material quality. It is especially effective for the use of additives such as CMC, gums, and powders that are difficult to dissolve.

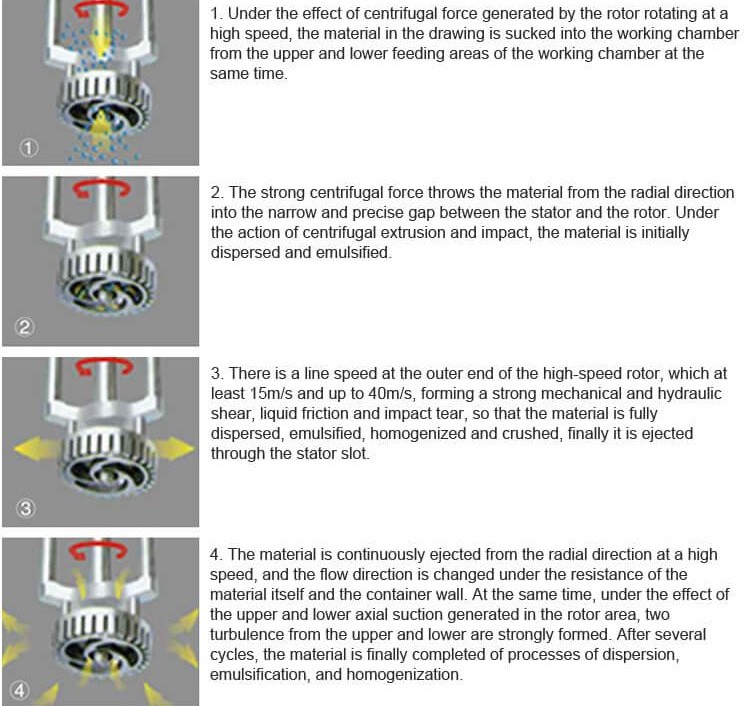

Working Principle

The machine is compact in structure, small in size, light in weight, easy to operate, low in noise and stable in operation. Its biggest feature is that it does not grind materials in production, and combines high-speed shearing, mixing, dispersing and homogenizing.

The shearing head adopts a daw type and two-way suction structure, which avoids dead angles and eddies caused by difficulty in inhalation of the upper material. The high-speed rotating rotor produces a strong shear force that causes the material to break radially into the narrow, precise gap between the stator and the rotor. The material is subjected to centrifugal extrusion, impact and the like, thereby being sufficiently dispersed, mixed, and emulsified.

Note: If the machine is used in a vacuum or on a pressurized container, an additional mechanical seal is required.

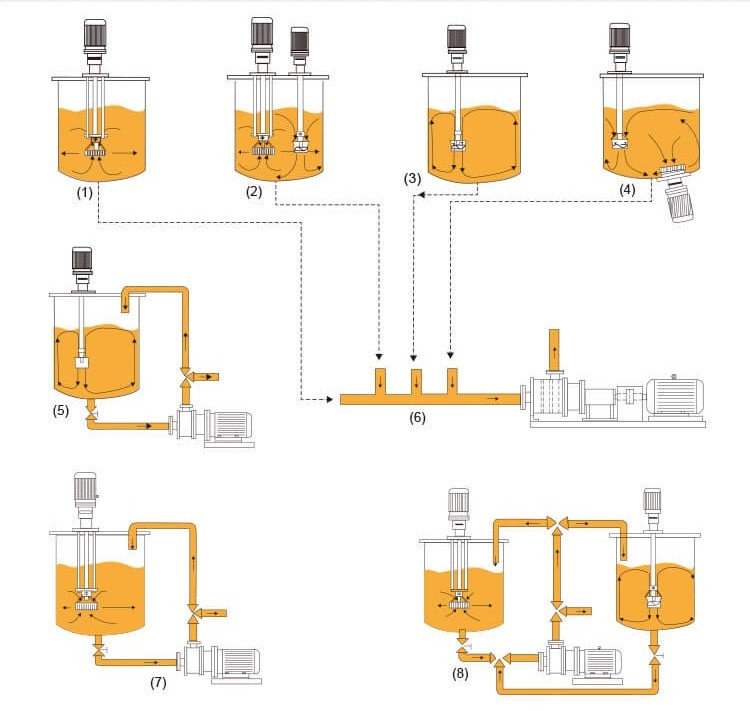

Intermittent High Shear Working Process

Product Showcase

WORK HEAD TYPE

Common Structural Types

According to the characteristics of the materials and the user’s process requirements, we will choose the appropriate structural type and speed.

Combination And Collocation

Product detail pictures:

Related Product Guide:

Cooperation

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Leading Manufacturer for Heated Planetary Mixer - High Shear Emulsifier Type II – Qiangzhong, The product will supply to all over the world, such as: Indonesia, Salt Lake City, French, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

Discount Price Seasoning Mixer Machine - Wate...

-

Top Quality Soybean Milk Colloid Mill - JM-F S...

-

Hot Selling for Air Pressure Tank For Water Pum...

-

Hot Selling for Sanitary Heavy Duty Single Pin ...

-

2021 New Style Cheese Puffs Making Machine - M...

-

Cheap price Dairy Pump - Sanitary Centrifugal ...