Magnetic Stirring Tank

We specialize in manufacturing food and medical equipment, and know you better!Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries.

a PRODUCT PARAMETERS

|

Capacity |

Motor Power |

Tank Body |

Mixing Speed |

Inlet & Outlet |

|

(L) |

(kw) |

(mm) |

(r/min) |

Diameter(mm) |

|

100 |

0.25 |

600×550 |

50-378 |

38 |

|

200 |

0.25 |

700×800 |

50-378 |

38 |

|

300 |

0.37 |

800×750 |

50-378 |

38 |

|

400 |

075 |

800×800 |

50-378 |

38 |

|

500 |

0.75 |

840×1000 |

50-378 |

38 |

|

600 |

0.75 |

900×1000 |

50-378 |

38 |

|

700 |

1.1 |

950×1000 |

50-378 |

38 |

|

800 |

1.1 |

950×1220 |

50-378 |

38 |

|

900 |

1.1 |

1010×1220 |

50-378 |

38 |

|

1000 |

1.1 |

1060×1220 |

50-378 |

51 |

a PRODUCT PARAMETERS

|

1000 |

1.1 |

1060×1220 |

50-378 |

51 |

GJ PRODUCT STRUCTURE

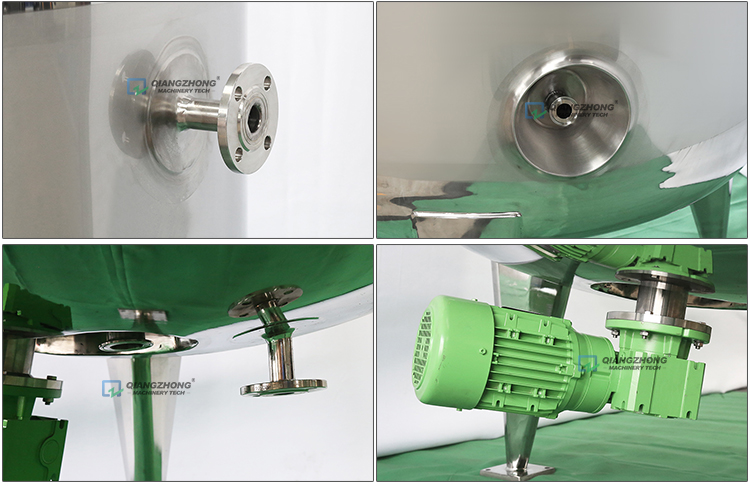

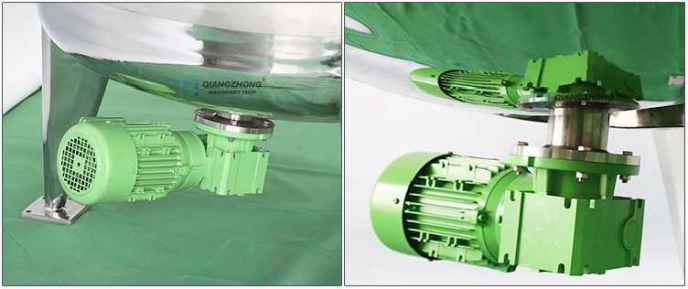

Magnetic mixing tank has characteristics of no leakage, fully sealed, corrosion resistance and energy saving. Because of its non-contact transmission torque, taking static seal to replace dynamic seal, it solves the leakage problem that other shaft seals cannot overcome. Since all materials and the stirring components operate in a sterile and sanitary state, the magnetic stirring tank is an ideal replacement for processing machines in the industries of pharmaceutical, fine chemicals, cosmetics and bioengineering. It is a sterile liquid mixing tank with stirring device installed at the bottom or sideways if necessary, enabling CIP and SIP.

- Welded isolation sleeve static dead seal replaces dynamic mechanical seal, that completely solves the leakage problem of dynamic mechanical seal.

- Simple structure, easy to disassemble and clean, no dead corner.

- The agitator is installed at the bottom, and the mixing blade is unique in design, which can be adapted to agitation and mixing of various media, and can be stirred in the case of few materials. Simple structure, easy to disassemble, easy to clean, no dead ends.

- The standardized design allows the excellent components to be interchanged on different mixers.

Sanitary magnetic stirrer is an equipment designed primarily to confirm to GMP standards in the pharmaceutical, biotechnology, and food industries, which is featured by small size, reasonable structure, excellent performance and reliable use. It is a stirring device applicable to all kinds of stainless steel reaction tanks and liquid tanks. It is mainly composed of internal magnetic steel, external magnetic steel, isolation sleeve and transmission motor.

The parts in contact with materials are all made of stainless steel 316L7304, and it is through the permanent magnet coupling to drive the stirring shaft to work. It uses the static seal of the insulating sleeve isolation method to replace the dynamic seal of the drive shaft which completely solves various unavoidable leakage problems of mechanical seal.

The stirring impeller rotates to generate a vortex, and the dissolvable powder or liquid material is sucked into the vortex and rapidly absorbed into the stirring impeller. The centrifugal force of impeller rotation impacts the material from the outer diameter of the impeller to the tank wall in the form of radiation. The material rises and circulates with the collision force, and is then sucked back to the suction end of the impeller. The impeller’s thrust causes the material to move and stir continuously, and is homogenized, mixed, dissolved and dispersed, and finally forms a stable and delicate product.