Manufacturer for Soap Making Melting Tank - Electric heating vacuum stirring and dispersion system – Qiangzhong Detail:

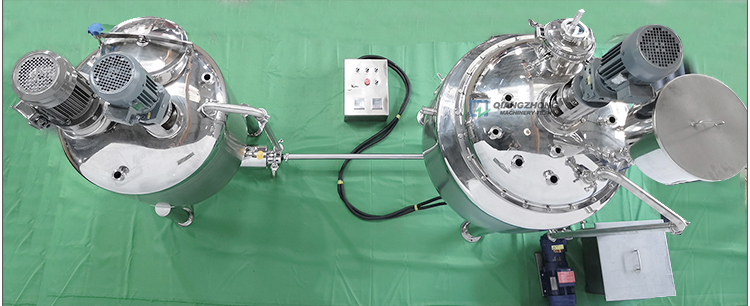

Electric-heating Vacuum Mixing and Dispersion System

We specialize in manufacturing food and medical equipment, and know you better! Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries.

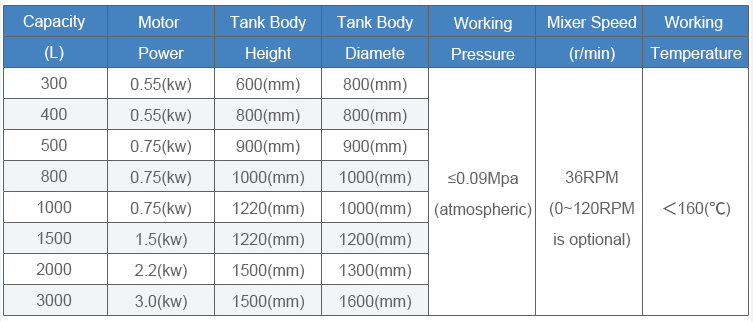

PRODUCT PARAMETERS

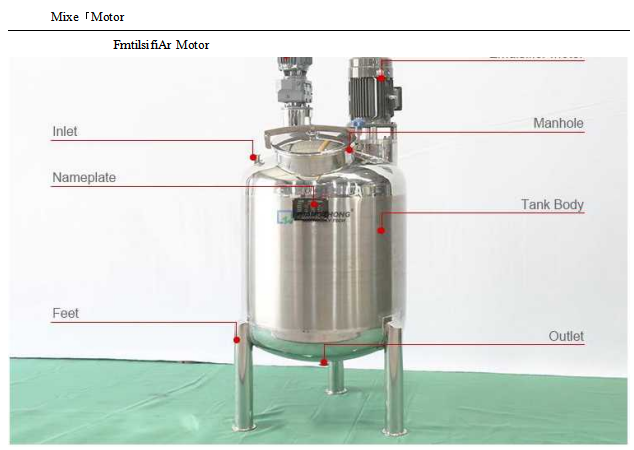

PRODUCT STRUCTURE

Equipment Structure: oval upper cover with manhole, lower oval bottom head, bottom discharge, vertical feet. Main functions of the electric-heating mixing tank: heating (heating the medium in the jacket by the heaters, transferring heat energy, and indirectly heating the material in the tank, with automatic temperature control), heat insulation, cooling and stirring.

Stirring tank having energy dispersion, corrosion, production capacity, simple structure, and easy cleaning. Suitable for continuous production of high-performance homogenizer or loop processing apparatus needs stirring, dispersing, broken material. Air respirators, sight glasses, pressure gauges, manholes, cleaning balls, casters, thermometers, level gauges and control systems can be configured according to customer requirements.

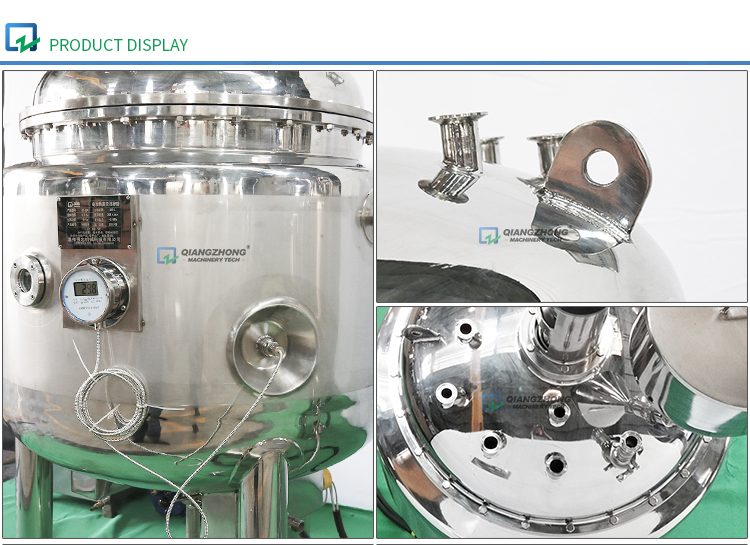

• The clamp is applicable for ports, smooth and easy to clean, and also easy to assemble and disassemble.

• Easy to install and use: just plug in the required power cable (380V/three-phase four-wire) in the terminal of the electric control box, then add materials and heating medium to the inside of the tank and the jacket respectively.

• Stainless steel 304/316L is used for the tank liner and parts in contact with the material. The rest of the tank body is also made of stainless steel 304.

• Both the internal and external is mirror polished (roughness Ra<0.4um), neat and beautiful.

• A movable baffle is installed in the tank to meet the mixing and stirring requirements, and there is no cleaning dead angle. It is more convenient to remove and wash it.

• Mixing at fixed speed or variable speed, meeting the requirements of different loading and different process parameters for agitation (it is frequency control, online real-time display of stirring speed, output frequency, output current, etc.).

• Agitator operation state: the material in the tank is mixed quickly and evenly, the load of the stirring transmission system is running smoothly, and the load operation noise <40dB(A) (lower than the national standard of <75dB(A), which greatly reduces the laboratory’s sound pollution.

• The agitator shaft seal is sanitary, wear-resistant and pressure-resistant mechanical seal, which is safe and reliable.

• It is equipped with special equipment to prevent the reducer from contaminating the material inside the ank if there is any oil leakage, very safe and reliable.

Product detail pictures:

Related Product Guide:

Cooperation

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Manufacturer for Soap Making Melting Tank - Electric heating vacuum stirring and dispersion system – Qiangzhong, The product will supply to all over the world, such as: Iraq, New Zealand, Brasilia, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

-

2021 China New Design Centrifugal Electric Moto...

-

Original Factory Dc Diaphragm Pump - Self-prim...

-

Reasonable price Essential Orange Oil Extractio...

-

Europe style for High Shear Liquid Mixer - Hig...

-

Special Price for 150 Hp Centrifugal Pump Price...

-

Special Price for Pipe Holder Iso Bsp 2 - JM-F...