Manufacturing Companies for Coffee Grinder Professional - Double Emulsification and Mixing Tank – Qiangzhong Detail:

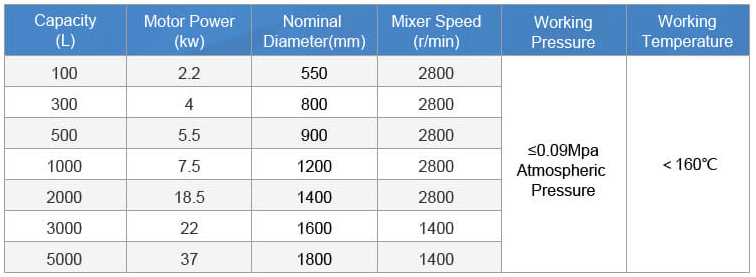

Product Parameters

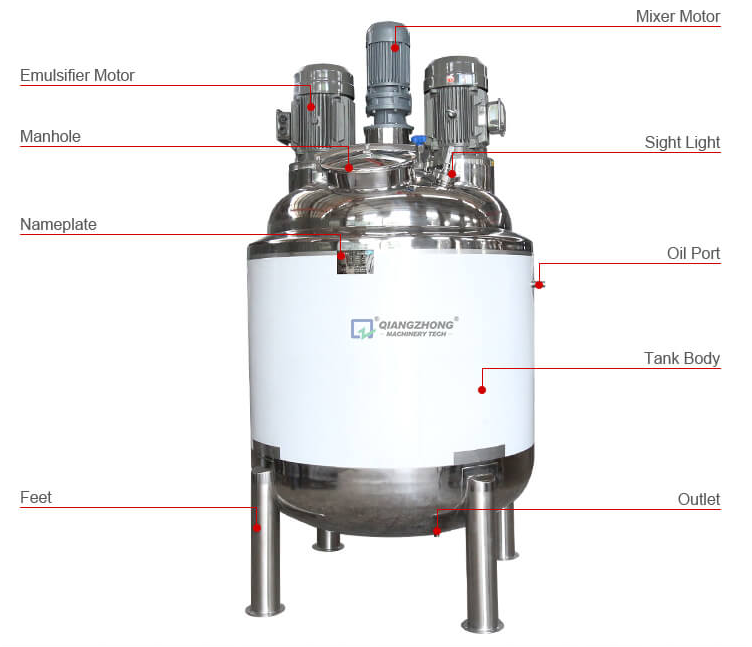

Product Structure

The tank is capable of distributing one or more phases to another continuous phase efficiently, quickly and uniformly, in which case the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction and impact in the narrow gap between the stator and the rotor. A combination of tearing and turbulence. Therefore, the incompatible solid phase, the liquid phase, and the gas phase are uniformly and finely dispersed and emulsified under the action of the corresponding mature process and an appropriate amount of additives, and the high-frequency cycle reciprocates to finally obtain a stable high-quality product.

●Mixing tank mainly consists of tank body, cover, agitator, supporting feet, transmission device and shaft seal device.

●Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel and other materials according to specific requirements.

●Tank body and cover can be connected by flange seal or welding. Also they could be with holes for purpose of feeding, discharging, observation, temperature measurement, manometry, steam fractionation and safety vent.

●Transmission devices (a motor or a reducer) are installed on top of the cover and the agitator inside the tank is driven by stirring shaft.

●Shaft sealing device can be used machine seal, packing seal or labyrinth seal, they are optional according to customer’s need.

●Agitator type could be impeller, anchor, frame, spiral type, etc.

Product Showcase

Stirring Paddle Type

Common Structure of the Stirring Paddle

We will select the appropriate stirring paddle type and stirring speed according to the characteristics of the mixing material and the user’s process requirements.

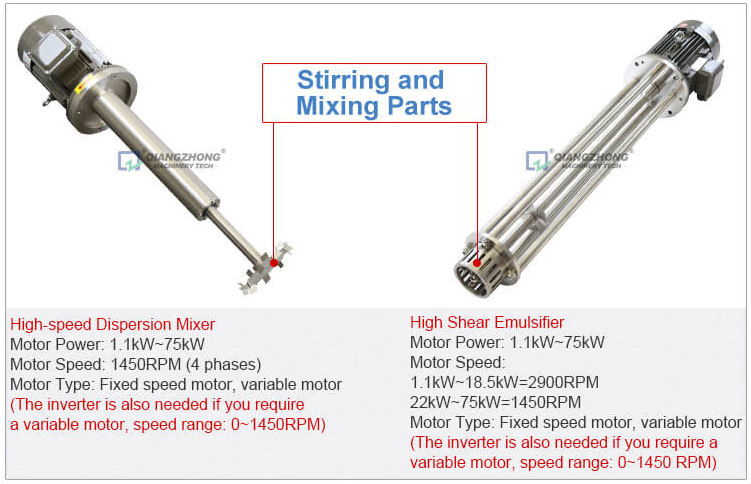

In addition to the above types of stirring paddles, some mixing tanks may also be equipped with a high shear emulsifier or a vane type dispersing mixer Its strong mixing force can quickly disperse and mix the materials.

Product detail pictures:

Related Product Guide:

Cooperation

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Manufacturing Companies for Coffee Grinder Professional - Double Emulsification and Mixing Tank – Qiangzhong, The product will supply to all over the world, such as: Islamabad, Saudi Arabia, Sevilla, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

OEM Supply Asphalt Tank - Rectangle Port Rotor...

-

Good User Reputation for Cream Tank - Single-s...

-

Newly Arrival Factories For Making Jam - Air F...

-

High Quality for Restaurant Cooking Machine - ...

-

Factory Cheap Continuous Butter Making Machine ...

-

factory low price 300l Tank - Sanitary Beverag...