Manufacturing Companies for Rotate Cook Pot - Single-layer closed high-shear emulsification tank – Qiangzhong Detail:

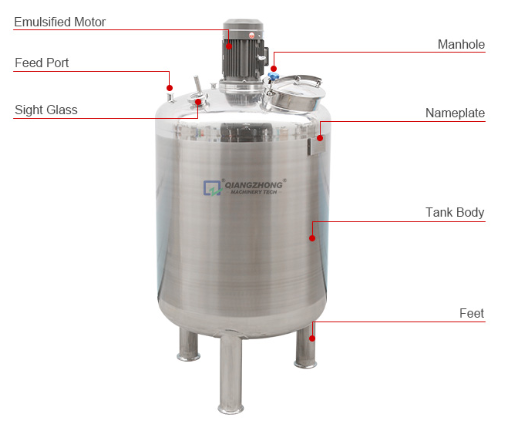

Single-wall Homogenizing Tank

PRODUCT DESCRIPTION

This emulsification tank is equipped with three coaxial stirring mixers, suitable for stable homogenization and emulsification, and the emulsified particles are very small. The quality of the emulsification mainly depends on how the particles are dispersed in the preparation stage. The smaller the particles, the weaker the tendency to aggregate on the surface, and thus the less chance of the emulsification being destroyed. Relying on the mixing of reversing blades, homogeneous turbine and vacuum processing conditions, high-quality emulsification mixing effects can be obtained.

The function of the emulsification tank is to dissolve one or more materials (water-soluble solid phase, liquid phase or jelly, etc.) in another liquid phase and hydrate it into a relatively stable emulsion. It is widely used in the emulsification and mixing of edible oils, powders, sugars and other raw and auxiliary materials. The emulsification and dispersion of certain coatings and paints also require emulsification tanks. It is especially suitable for some insoluble colloidal additives, such as CMC, xanthan gum, etc.

Application

The emulsification tank is suitable for cosmetics, medicine, food, chemistry, dyeing, printing ink and other industries. It is especially effective for the preparation and emulsification of materials with high matrix viscosity and relatively high solid content.

(1) Cosmetics: creams, lotions, lipsticks, shampoos, etc.

(2) Medicines: ointments, syrups, eye drops, antibiotics; etc.

(3) Food: jam, butter, margarine, etc.

(4) Chemicals: chemicals, synthetic adhesives, etc.

(5) Dyed products: pigments, titanium oxide, etc.

(6) Printing ink: color ink, resin ink, newspaper ink, etc.

Others: pigments, waxes, paints, etc.

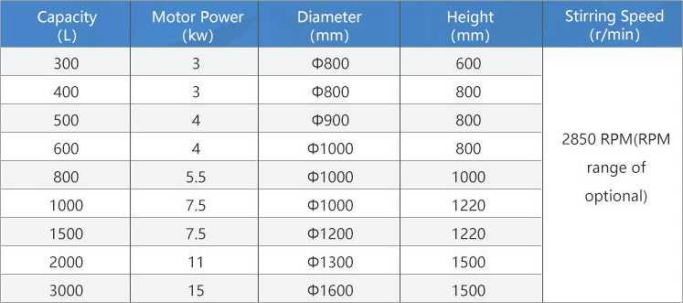

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

* the above table is for reference only, can customize according to customer’s requirements.

* this equipment can customize according to customer’s material, need to comply with process, such as meet high viscosity, homogeneous function strengthen, heat-sensitive materials such as requirements.

WORKING PRINCIPLE

Its working principle is that the centrifugal force generated by the high-speed and strong rotating rotor of the emulsifying head throws the material into the narrow and precise gap between the stator and the rotor from the radial direction. The materials are simultaneously subjected to centrifugal extrusion and impact forces to be dispersed, mixed and emulsified. The tank has the advantages of humanized structure, customizable volume, easy operation, safety and hygiene, and stable operation. It integrates high-speed shearing, dispersion, homogenization and mixing.

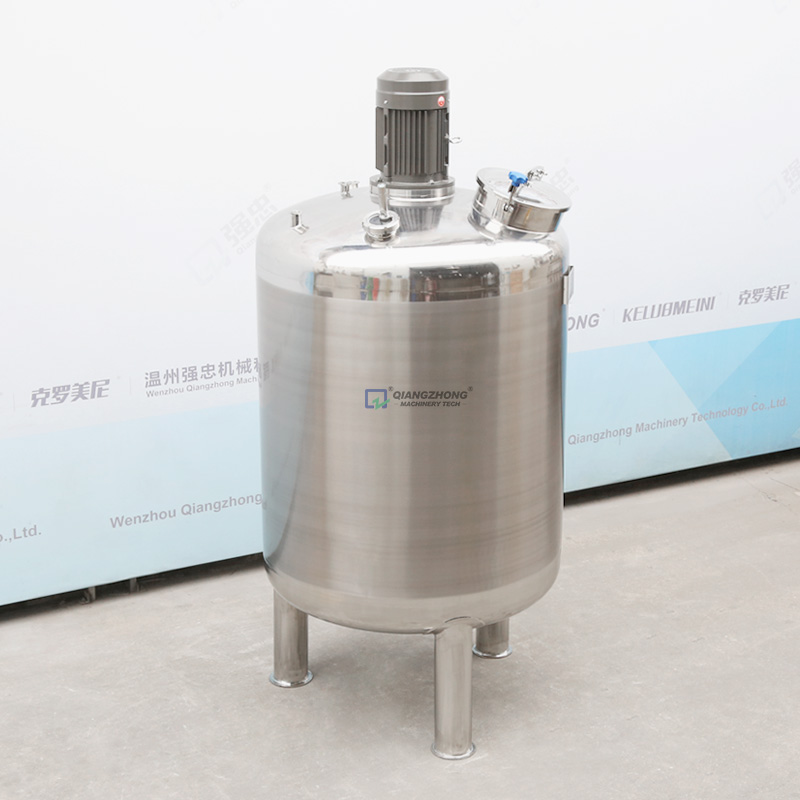

Product detail pictures:

Related Product Guide:

Cooperation

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for Manufacturing Companies for Rotate Cook Pot - Single-layer closed high-shear emulsification tank – Qiangzhong, The product will supply to all over the world, such as: Peru, Spain, Vancouver, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

-

Competitive Price for Drum Pump Chemical - San...

-

Good Wholesale Vendors Chocolate Gear Pump - S...

-

Best quality Equipment For The Production Of Ch...

-

Special Price for High Shear Lab Emulsifying Mi...

-

OEM/ODM China 110v Electric Rice Cooker - Vacu...

-

Discount Price Heavy Duty Mixer - High Shear E...