Non-standard custom mixing tank

To mix powder or paste material, make different qualitative material mixing. Is a horizontal trough the single oar mix,impeller for shaft, easy to clean.

Product Introduction

This series of equipment completely according to the national “drug production quality management norms” GMP “requirements of equipment; And press the “steel welding atmospheric vessel” (JB / 4735-1997), and other standard design, manufacture, suitable for purification area of pharmaceutical industry, food industry, the liquid preparation of brewing (product) process and all kinds of water treatment process, at the same time to undertake the design, manufacture of all kinds of not marked container. 1, the material is 316 I or 304, the polishing treatment on the surface, the surface roughness Ra0.4 microns. 2, stirring in the top and bottom mechanical stirring: top mixer mixing forms are: the pusher, screw, anchor, scraping mounted or paddle mixer, etc.; Mix the material thoroughly. Stir in pieces at the bottom of the form are: magnetic stirring, pusher mixing, bottom mounted high shear emulsification head; Accelerated dissolution of the material and emulsion. Mixer mixing optional with constant speed or frequency control of motor speed, mastering the stirring speed can avoid too much faster and produce bubble. Pieces of stainless steel electric control cabinet can be fully monitor equipment operation, and it can display temperature, stirring speed and other data. 3, configuration are: air respirator, thermometer, steam sterilization mouth, health into the hole, the level and liquid level control system, universal rotating cleaning ball or configured according to customer requirements. 4, jacket can according to customer requirements, coil and the whole jacket, honeycomb jacket. 5, insulation according to customer requirements, using rock wool: polyurethane foam, pearl cotton filling, shell can according to customer requirements for polishing and drawing or inferior smooth processing. 6, specifications: 301 – 30000 I.

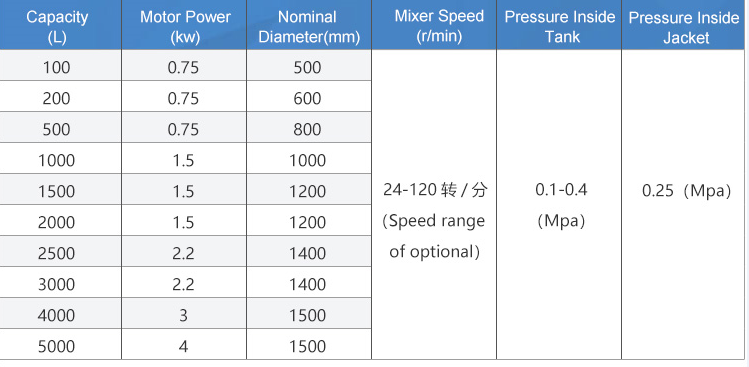

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

• Agitation tank by mixing tank, mixing tank cover, mixer, bearing, gear, shaft sealing device, etc.

• Mixer, mixing tank, mixing tank cover to choose material such as shaft seal can be selected according to different technical requirements of carbon steel or stainless steel and other materials to produce.

• Mixing tank and tank cover flange seal connection or welding connection can be used. Mixing tank and tank cover according to technological requirements the feeding and discharging, observation, temperature, pressure, steam fractionation, safety vent pipe hole process.

• Drum to cover the upper configuration has a transmission device (motor and reducer), driven by a drive shaft mixer mixing tank.

• Shaft sealing device can use machine to seal or packing, a variety of forms such as the labyrinth seal (according to user needs to determine).

• As users require different production process, the blender configurable plasma type, anchor type, frame type, spiral, and other forms.

• Material contact part is stainless steel SUS304 or 316 make our products conform to the requirement ofGMP.

PRODUCT STRUCTURE