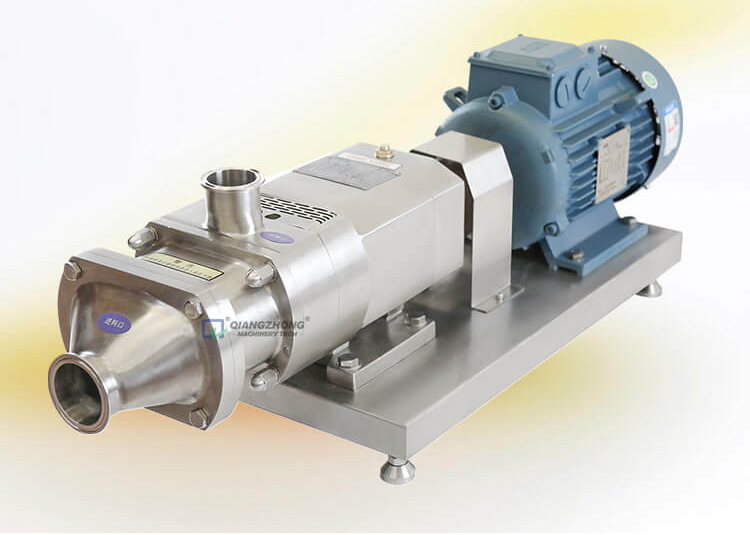

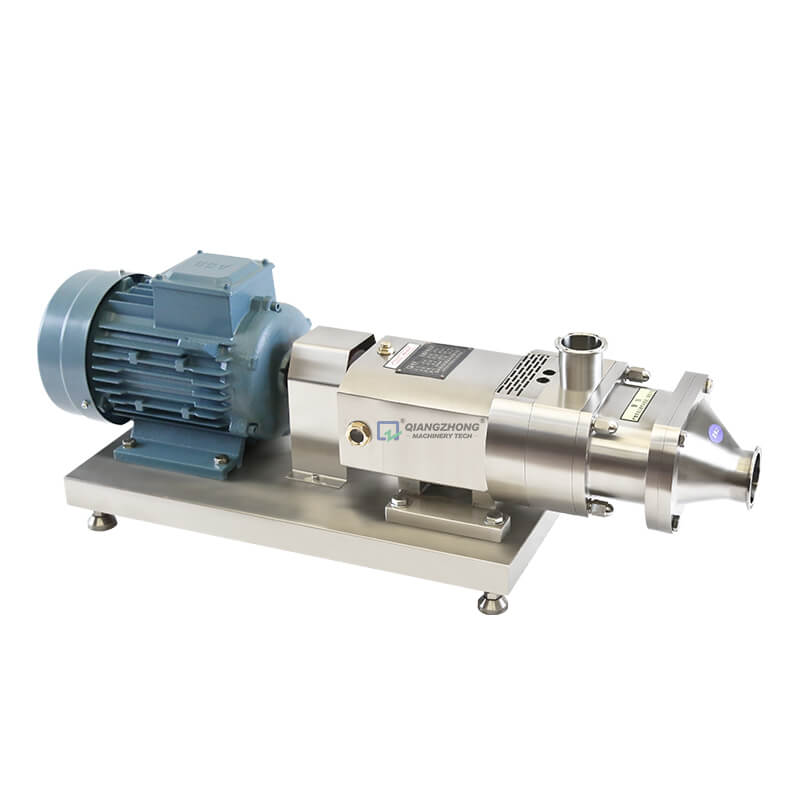

OEM Customized Wax Vapor Tank - Twin Screw Pump – Qiangzhong Detail:

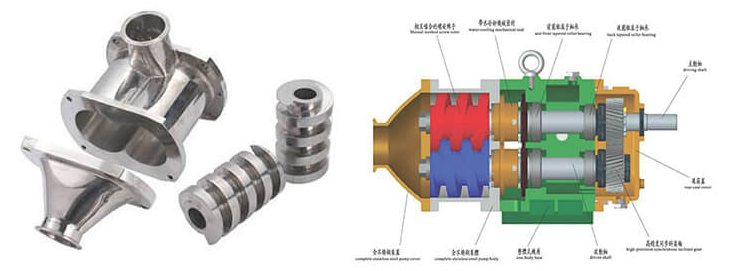

Product Structure

Twin screw conveying pump adopts open and modular sanitary structure. The whole system consists of three main parts: pump body, transmission gear box and motor. In line with the stainless steel sanitary standard, all parts in contact with the materials are made of high-grade and high-quality 304/316L sanitary stainless steel. The transmission parts are made of three kinds of materials: spheroidal graphite, cast steel and stainless steel to maintain the high grade and high quality of the equipment. The pump body, which is the core part of the entire system, consists of the front chamber cover, cavity, spiral rotor, drive shaft, machine enclosure, and mechanical seal. The drive shaft adopts a robust reinforced design with an integrated body structure, and a high-quality, high-strength special precipitation stainless steel material is used, which is solid-melted and hardened.

The gearbox is an important part of the entire system. Its power transmission system consists of a drive shaft and a driven shaft, which are both equipped with a pair of screw sleeves. The transmission process is accomplished through the synchronization gear installed opposite to the drive shaft, and the gear is high-precision synchronous helical gear (instead of spur gears with large noise and vibration) to ensure that the system operates more smoothly, quietly, more harmoniously and humanely. The gear box is made of spheroidal graphite, cast steel and stainless steel, which further improves the sanitary level and performance of the equipment system. The drive shaft adopts a robust reinforced design, and the transmission bearings only use high-strength, high-quality, high-performance bearings of internationally renowned brands. High-performance lubricated transmission grease further ensures that the system can cope with unexpected conditions and thus have a longer service life.

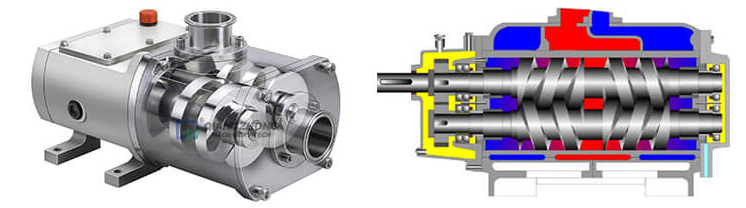

Working Principle

A specially designed pair of spiral systems mesh with each other, forming a series of dynamic space curved sealing surfaces between them. Due to the intermeshing of the spiral and the close fit of the spiral with the inner wall of the liner, a series of multiple sealed spaces are formed between the suction inlet and the discharge outlet of the pump. With the rotation and engagement of the screw, a continuous seal space is formed at the suction end of the pump, the liquid in the suction chamber is sealed therein, and is continuously pushed along the suction chamber to the discharge end in a spiral axial direction. It continuously and smoothly discharges the liquid enclosed in the separate spaces, as if the nuts were continuously pushed forward while the spiral was rotating. This is the basic working principle of this series of twin screw pump.

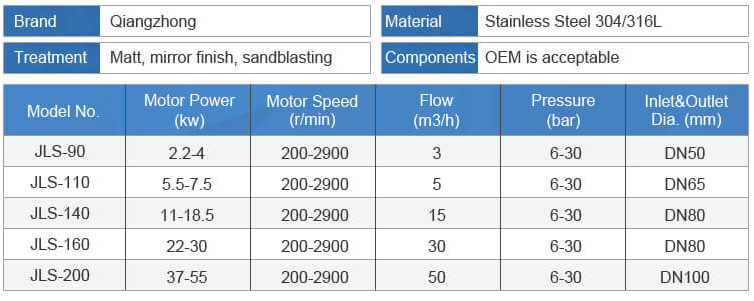

Parallel displacement pump has 5 series and 30 models of different products.

◎ Customers can choose the best application solution based on the production process and product status.

◎ Pump processing flow range: 0-145 m3/h

◎ Pressure difference between pump inlet and outlet: Usually 6-8 bars, up to 26 bars.

◎ Pump speed: freely adjustable, up to 2,900 rpm

◎ Viscosity of pump conveying material: up to 2,000,000 cSt (cps)

◎ The rotation direction of the pump: adjustable as needed

◎ Pump operating temperature range: up to 150 °C.

There are 3 connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection.

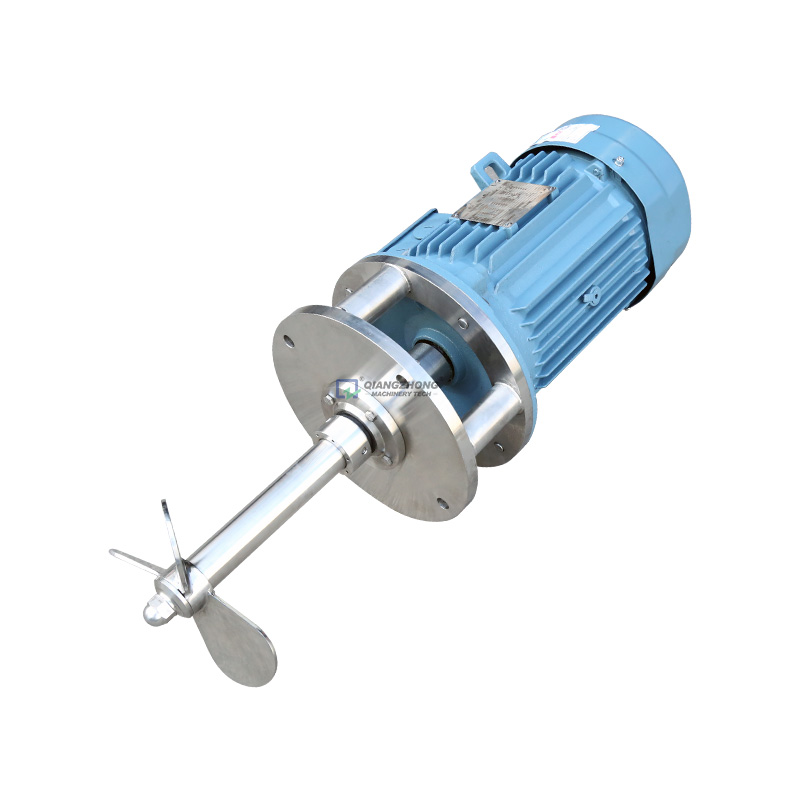

Product Showcase

Product detail pictures:

Related Product Guide:

Cooperation

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for OEM Customized Wax Vapor Tank - Twin Screw Pump – Qiangzhong, The product will supply to all over the world, such as: Seychelles, Croatia, Brazil, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

-

Best-Selling Machines For Spice Mixing - Micro...

-

Hot-selling Electric Meat Mixer - High-speed m...

-

Massive Selection for Chocolate Paste Making Ma...

-

Factory Cheap Mixer And Homogenizer Machine - ...

-

Professional China Animal Feed Grain Grinder -...

-

Factory Price 50000l Fermentation Tank - JM-W ...