Professional Design Putty Mixer Paint Mixer - High-speed mixing cylinder – Qiangzhong Detail:

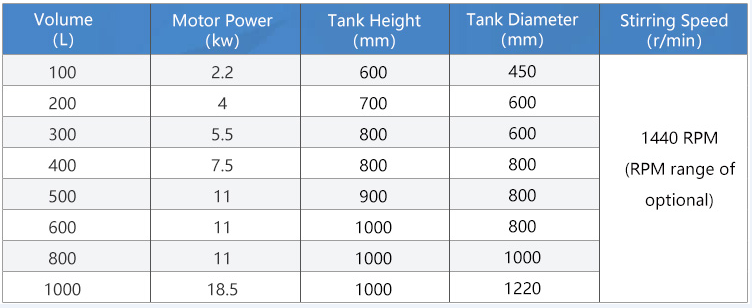

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

PRODUCT STRUCTURE

The equipment uses high-speed bottom mixing device of impeller and can well dissolute toffee, powder additives, and etc, and it’s currently the most productive model of high-speed mixing tank. The equipment is characterized by short time of mixing and homogenization, without affecting performance of materials, ensuring original flavor, simple operation, small size and easy installation. It is an indispensable equipment for dairy, beverage and pharmaceutical industries.

At bottom of tank, rotor rotates at high-speed and produces high-pressure centrifugal flow with large flow rate. Afterwards materials pass through tiny gap between stator and rotor by strong shearing force, accompanied by other forces of impact, extrusion and grinding. At the same time, the high-pressure centrifugal flow makes materials rotate in vortex flow. After circulation of around 10 minutes, materials are quickly dissolved, dispersed, crushed, ground, mixed, homogenized and emulsified to form a fine slurry.

HYG series high-speed mixing tank has a much better mixing performance compared with traditional mixing equipment. Traditional mixing equipment takes a long time to process and mix high-caking materials and materials of hard particles. But it becomes much easier to process them by JBG-type high-speed mixing tank instead. For JBG type high-speed mixing tank, all main parts are made of high quality stainless steel including tank body, rotor, stator, pipe fittings, valves, and etc. and both inner and outer surface are polish treatment. Mechanical seal is with large compensation structure, making the tank wear-resistant, durable and anti-damage. For JBG/X high-speed mixing tank, seal part can be opened to facilitate washing gaps of the equipment, suitable for processing organic, perishable materials and also mixing easy-to-dry materials.

Product detail pictures:

Related Product Guide:

Cooperation

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Professional Design Putty Mixer Paint Mixer - High-speed mixing cylinder – Qiangzhong, The product will supply to all over the world, such as: France, Kenya, Islamabad, Now, we professionally supplies customers with our main merchandise And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

-

Hot Selling for Mixer Perfume - New Tri-stage ...

-

High Quality for Juicer Maker Machine Industria...

-

2021 wholesale price Mixer Cooking - Shear and...

-

OEM manufacturer Tomato Strainer - Duplex Filt...

-

Factory Outlets Paint Mixing Machine For Car -...

-

2021 New Style Tank Equipment - Duplex Filter ...