Rapid Delivery for Liquid Mixer Machine - High Shear Emulsifier Type II – Qiangzhong Detail:

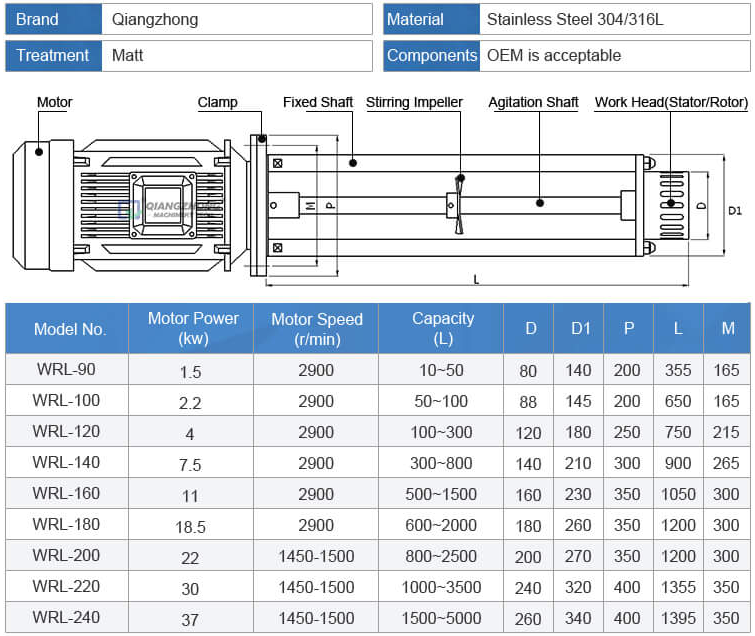

Product Parameters

*The above information is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to customer’s materials to meet the needs of the process, such as requiring greater viscosity, enhanced homogenization function, heat sensitive materials and other requirements.

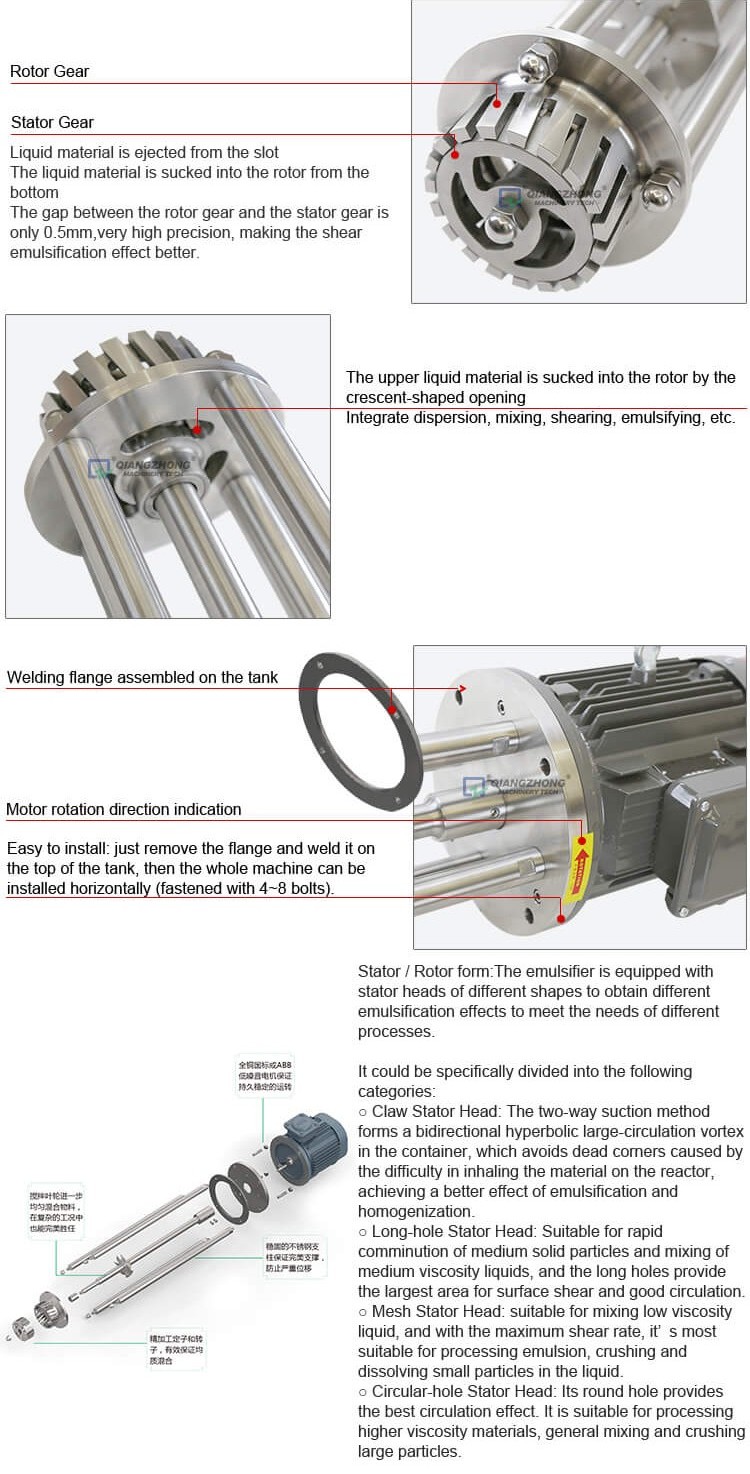

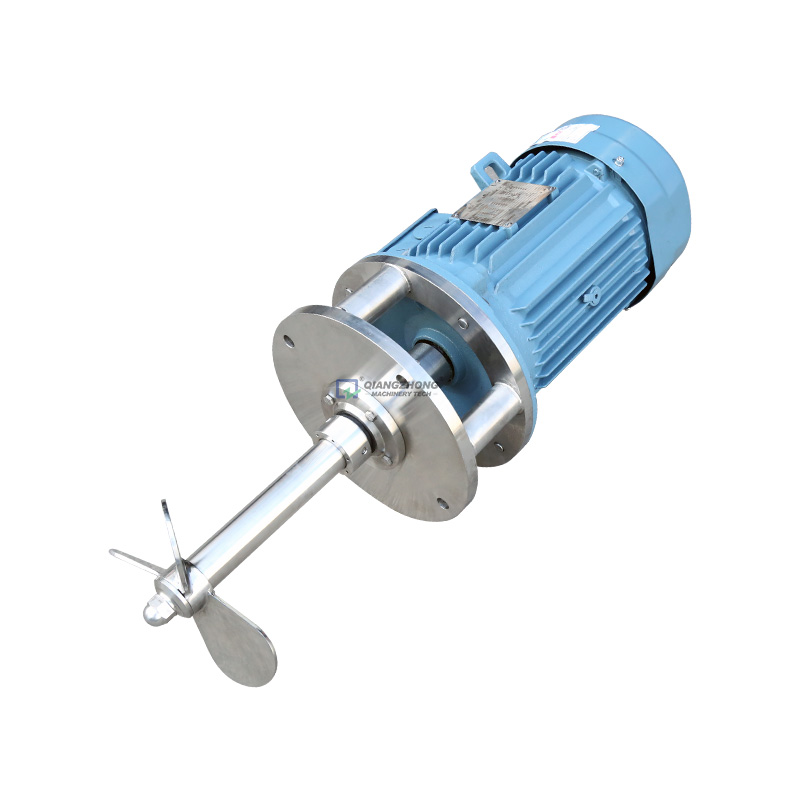

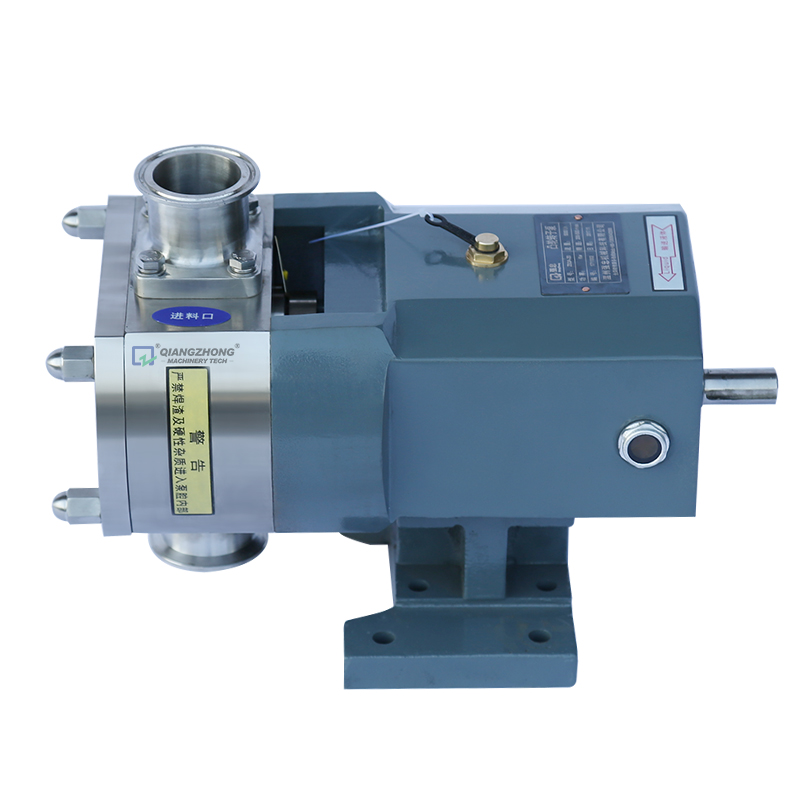

PRODUCT STRUCTURE

The emulsifier works by the high-speed rotor gear and the stator gear to fully and rapidly emulsify, homogenize and disperse the mixture in the vessel. It is widely used in food, dairy, beverage, bio-pharmaceutical, fine chemicals, pigments and other industries to improve production efficiency and material quality. It is especially effective for the use of additives such as CMC, gums, and powders that are difficult to dissolve.

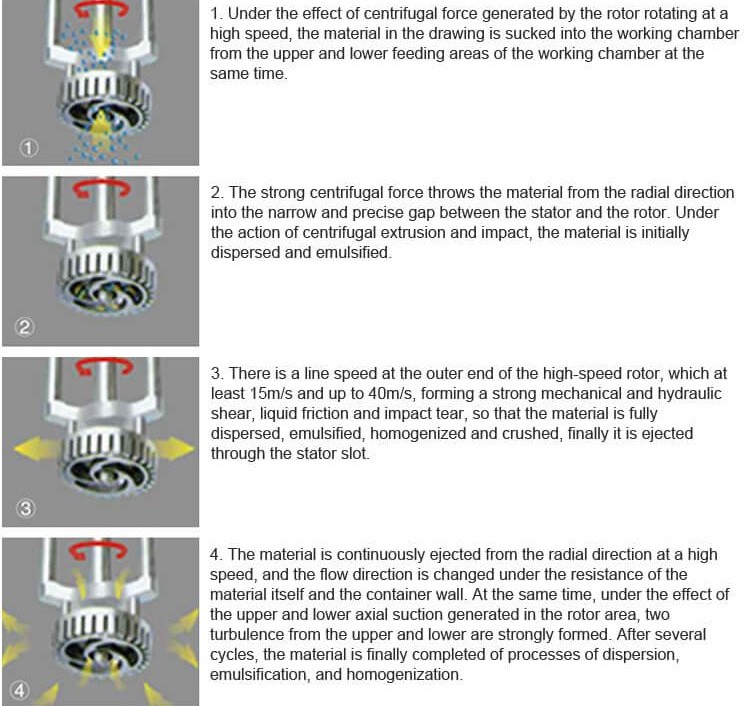

Working Principle

The machine is compact in structure, small in size, light in weight, easy to operate, low in noise and stable in operation. Its biggest feature is that it does not grind materials in production, and combines high-speed shearing, mixing, dispersing and homogenizing.

The shearing head adopts a daw type and two-way suction structure, which avoids dead angles and eddies caused by difficulty in inhalation of the upper material. The high-speed rotating rotor produces a strong shear force that causes the material to break radially into the narrow, precise gap between the stator and the rotor. The material is subjected to centrifugal extrusion, impact and the like, thereby being sufficiently dispersed, mixed, and emulsified.

Note: If the machine is used in a vacuum or on a pressurized container, an additional mechanical seal is required.

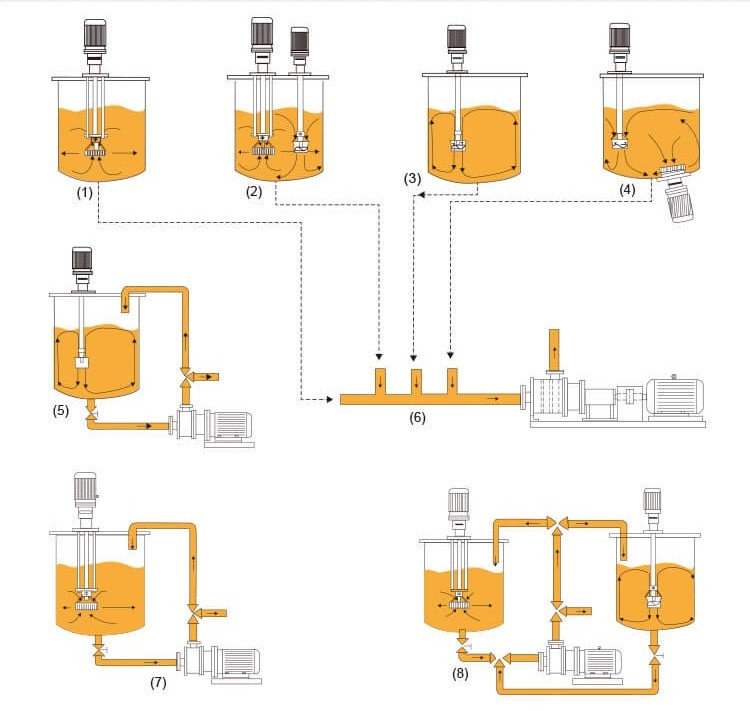

Intermittent High Shear Working Process

Product Showcase

WORK HEAD TYPE

Common Structural Types

According to the characteristics of the materials and the user’s process requirements, we will choose the appropriate structural type and speed.

Combination And Collocation

Product detail pictures:

Related Product Guide:

Cooperation

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Rapid Delivery for Liquid Mixer Machine - High Shear Emulsifier Type II – Qiangzhong, The product will supply to all over the world, such as: Toronto, Norway, Riyadh, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

New Delivery for Titanium Heat Exchanger Plate ...

-

Factory Price For Diesel Industry Screw Pump -...

-

factory Outlets for Stainless Steel Milk Boilin...

-

Factory Price For Gel Electrophoresis Tank - M...

-

Factory Cheap Edible Oil Filter Press - Precis...

-

High definition Garlic Cooker - Sanitary stain...