Rapid Delivery for Mixer Vessel - High Shear Emulsifier Type I – Qiangzhong Detail:

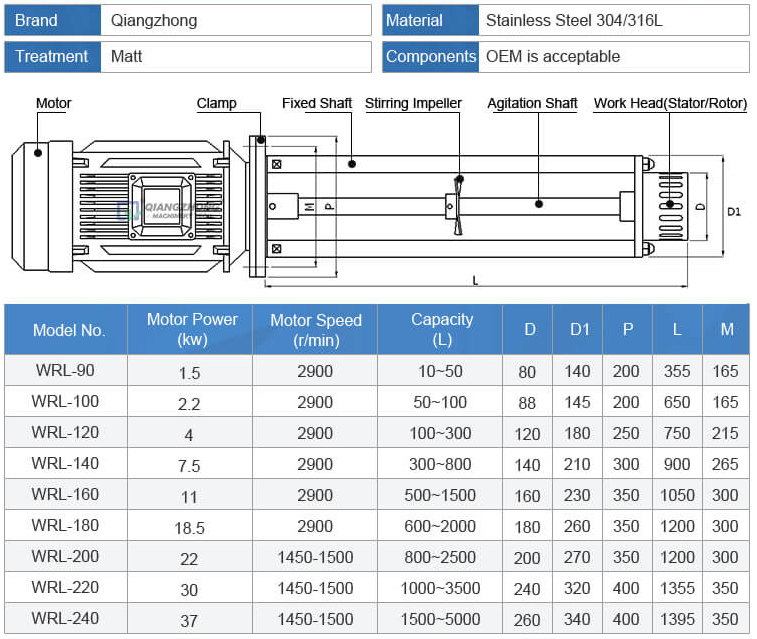

Product Parameters

*The above information is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to customer’s materials to meet the needs of the process, such as requiring greater viscosity, enhanced homogenization function, heat sensitive materials and other requirements.

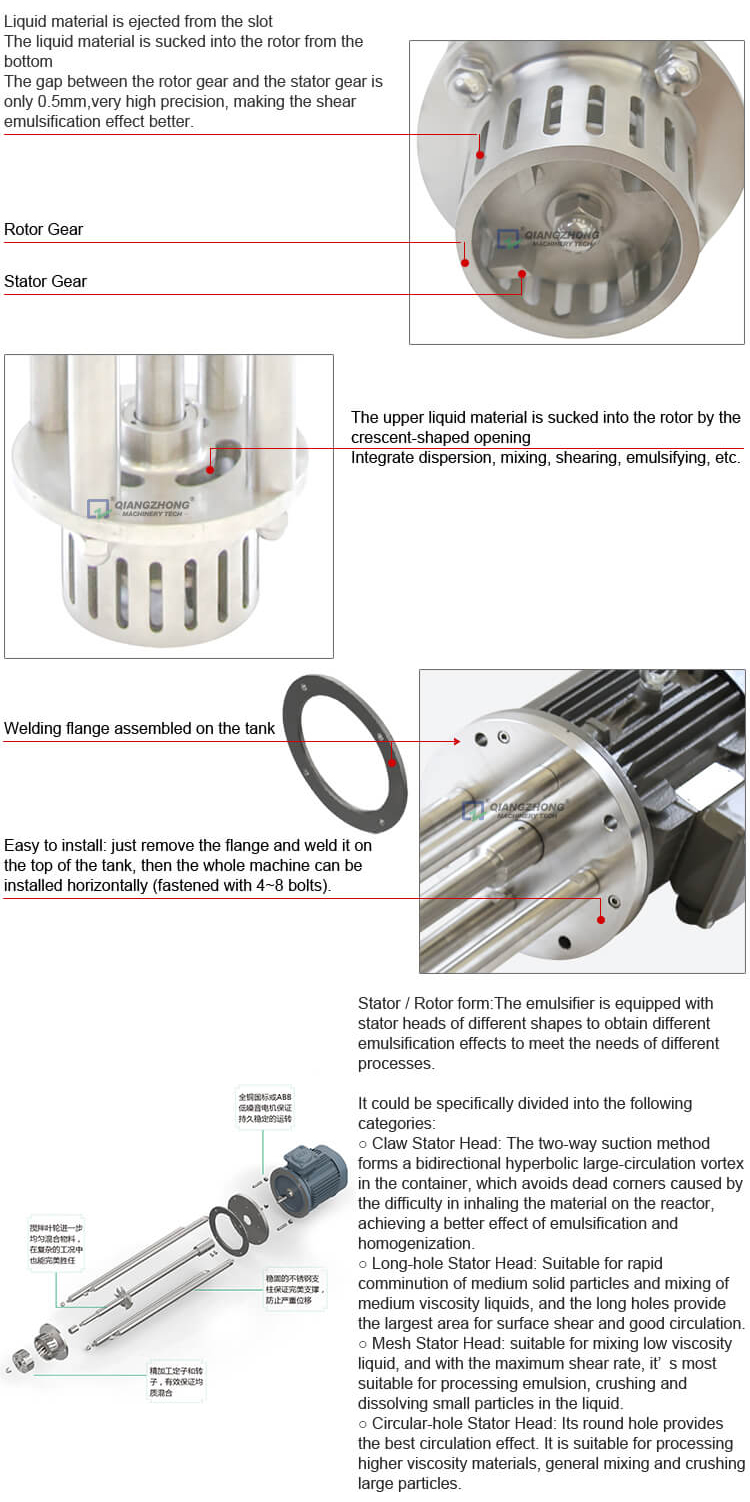

PRODUCT STRUCTURE

The emulsifier works by the high-speed rotor gear and the stator gear to fully and rapidly emulsify, homogenize and disperse the mixture in the vessel. It is widely used in food, dairy, beverage, bio-pharmaceutical, fine chemicals, pigments and other industries to improve production efficiency and material quality. It is especially effective for the use of additives such as CMC, gums, and powders that are difficult to dissolve.

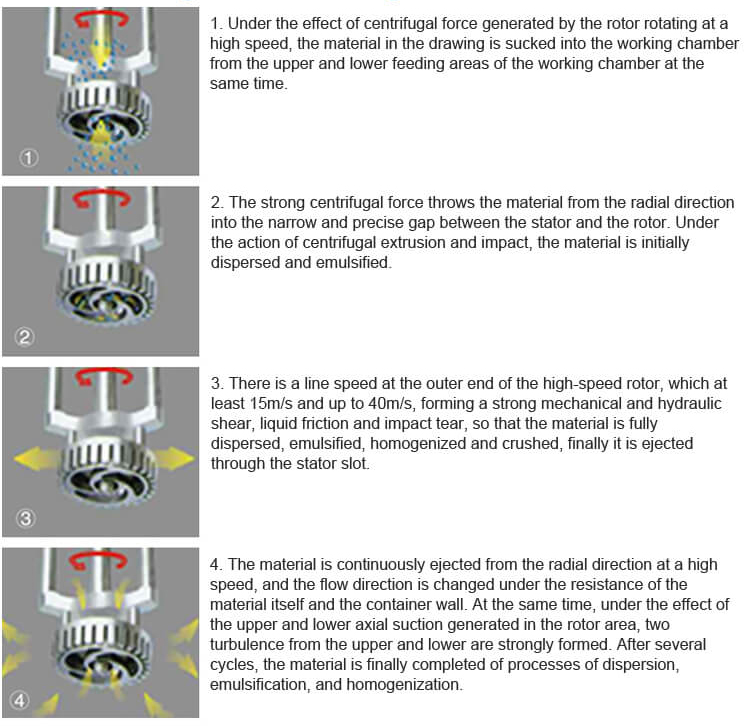

Working Principle

The machine is compact in structure, small in size, light in weight, easy to operate, low in noise and stable in operation. Its biggest feature is that it does not grind materials in production, and combines high-speed shearing, mixing, dispersing and homogenizing.

The shearing head adopts a daw type and two-way suction structure, which avoids dead angles and eddies caused by difficulty in inhalation of the upper material. The high-speed rotating rotor produces a strong shear force that causes the material to break radially into the narrow, precise gap between the stator and the rotor. The material is subjected to centrifugal extrusion, impact and the like, thereby being sufficiently dispersed, mixed, and emulsified.

Note: If the machine is used in a vacuum or on a pressurized container, an additional mechanical seal is required.

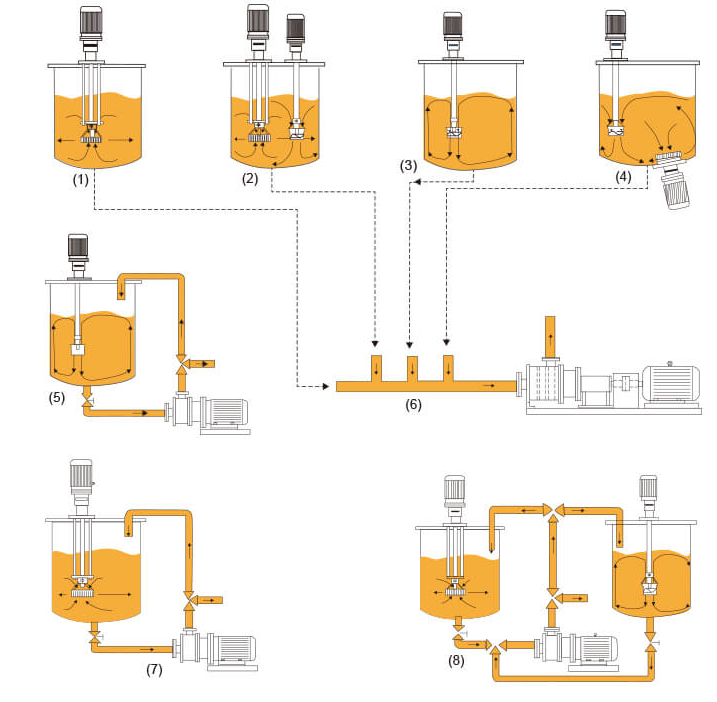

Intermittent High Shear Working Process

Product Showcase

WORK HEAD TYPE

Common Structural Types

According to the characteristics of the materials and the user’s process requirements, we will choose the appropriate structural type and speed.

Combination And Collocation

Product detail pictures:

Related Product Guide:

Cooperation

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with Rapid Delivery for Mixer Vessel - High Shear Emulsifier Type I – Qiangzhong, The product will supply to all over the world, such as: Argentina, Sweden, United Arab Emirates, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

OEM manufacturer Tomato Strainer - Single-core...

-

Factory Supply Mini Maize Mill - Open-type wal...

-

China New Product 3500w Induction Cooker - Ele...

-

China Cheap price Millipore Filter Housing - E...

-

Discount wholesale Cooking Chocolate - Multi-b...

-

Good Wholesale Vendors Automatic Coffee Grinder...