Reasonable price for 2000 Litre Conical Fermenter - High Shear Emulsifier Type III – Qiangzhong Detail:

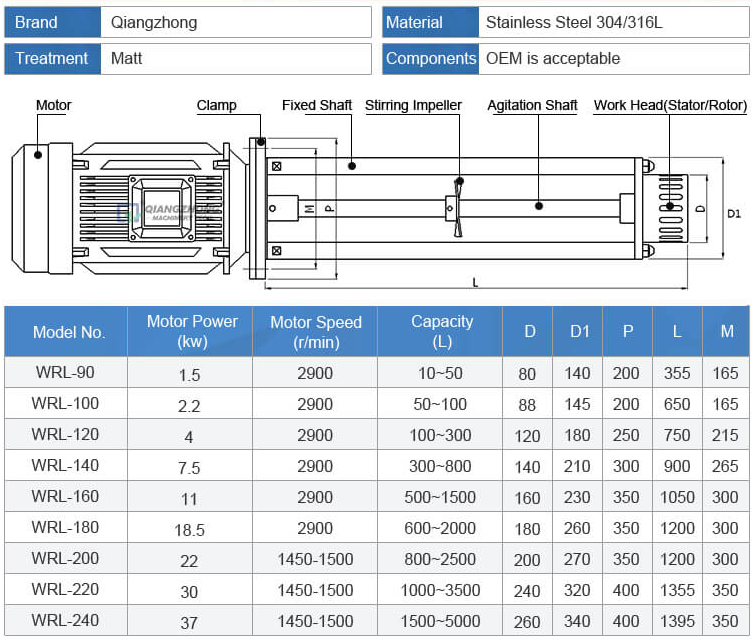

Product Parameters

This equipment can be customized according to customer,’s materials to meet the needs of the process such as requiring greater viscosity, enhanced homogenization function, heat sensitive materials and other requirements

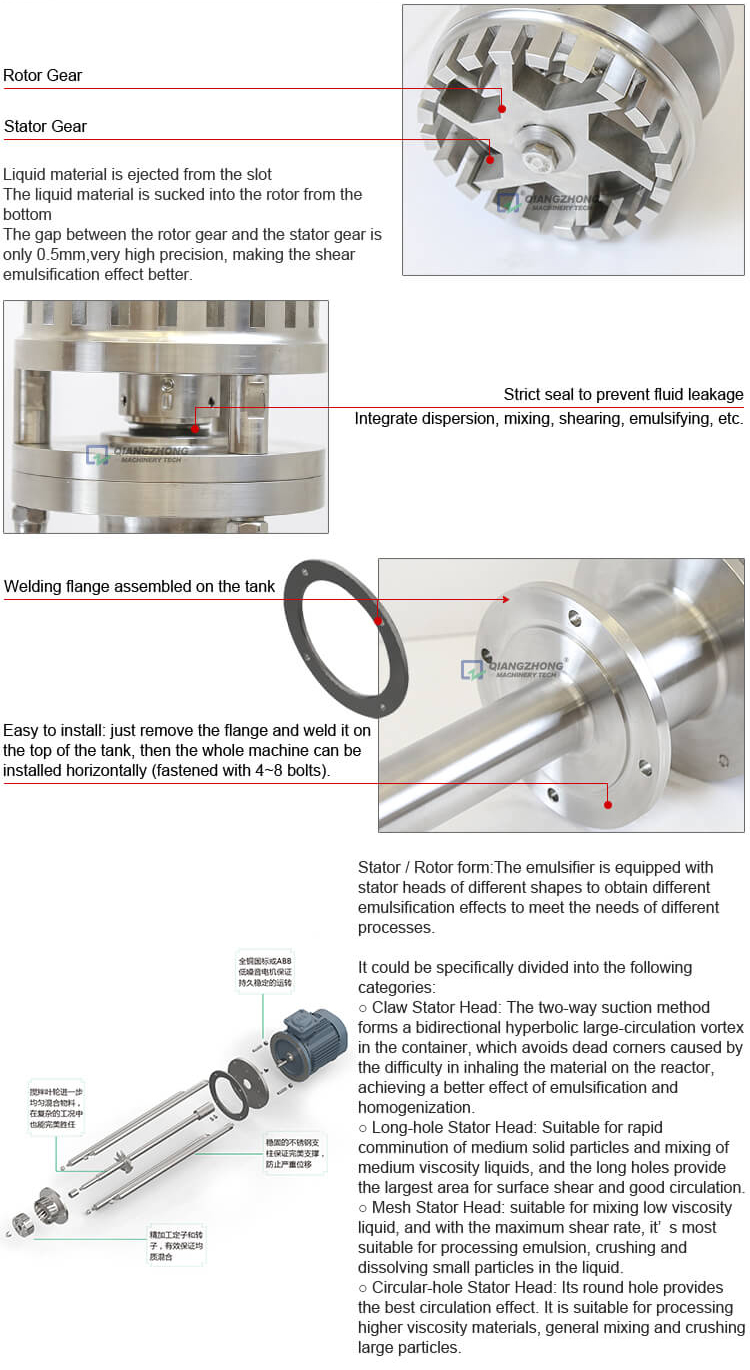

PRODUCT STRUCTURE

The emulsifier works by the high-speed rotor gear and the stator gear to fully and rapidly emulsify homogenize and disperse the mixture in the vessel. It is widely used in food dairy, beverage bio-pharmaceutical, fine chemicals, pigments and other industries to improve production efficiency and naterial quality. It is especially effective for the use of additives such as CMC, gums, and powders that are difficult to dissolve

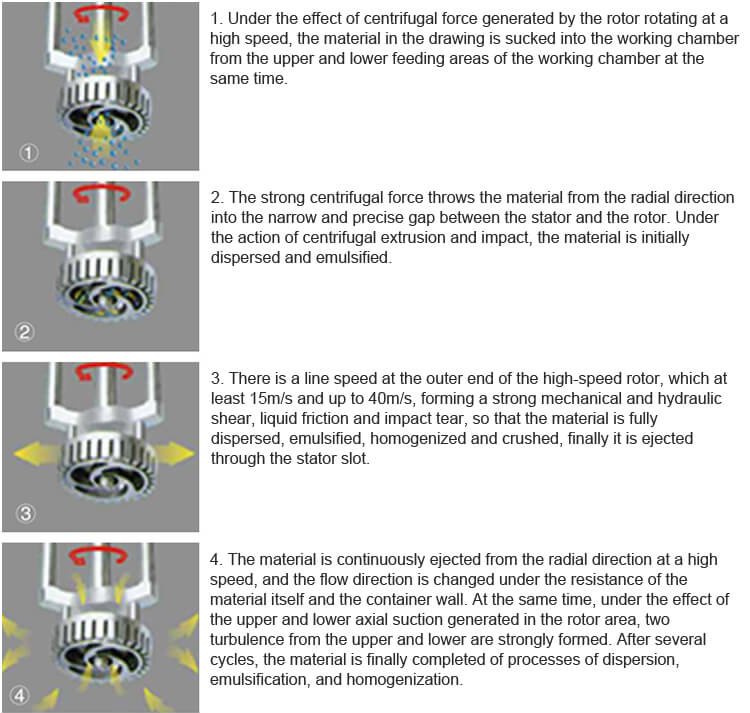

Working Principle

The machine is compact in structure, small in size, light in weight, easy to operate, low in noise and stable in operation. Its biggest feature is that it does not grind materials in production, and combines high-speed shearing, mixing, dispersing and homogenizing.

The shearing head adopts a claw type and two-way suction structure, which avoids dead angles and eddies caused by difficulty in inhalation of the upper material. The high-speed rotating rotor produces a strong shear force that causes the material to break radially into the narrow, precise gap between the stator and the rotor. The material is subjected to centrifugal extrusion, impact and the like, thereby being sufficiently dispersed, mixed, and emulsified.

Note: If the machine is used in a vacuum or on a pressurized container, an additional mechanical seal is required.

Intermittent High Shear Working Process

Product Showcase

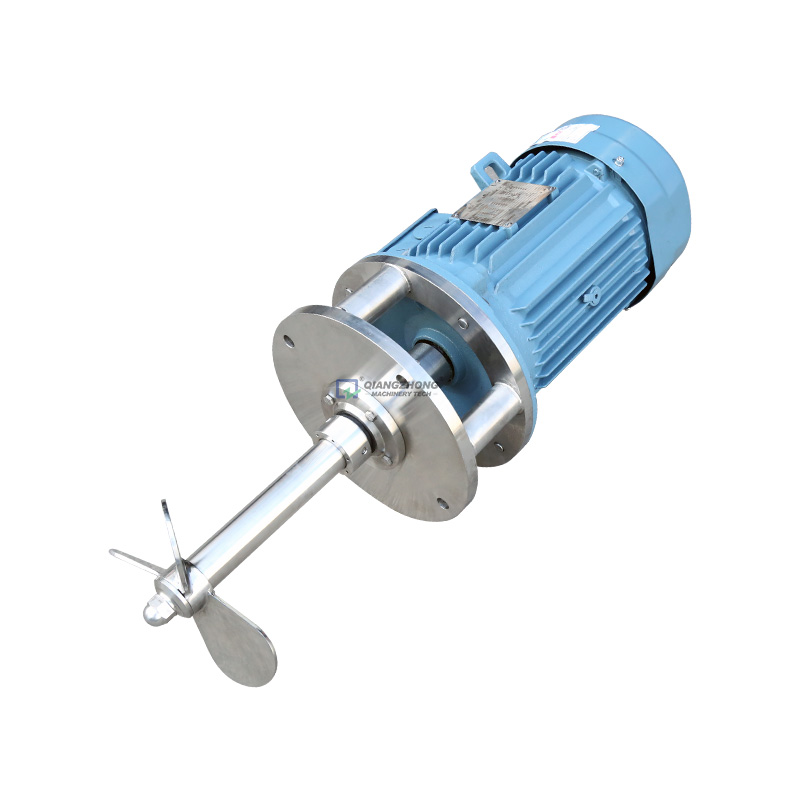

WORK HEAD TYPE

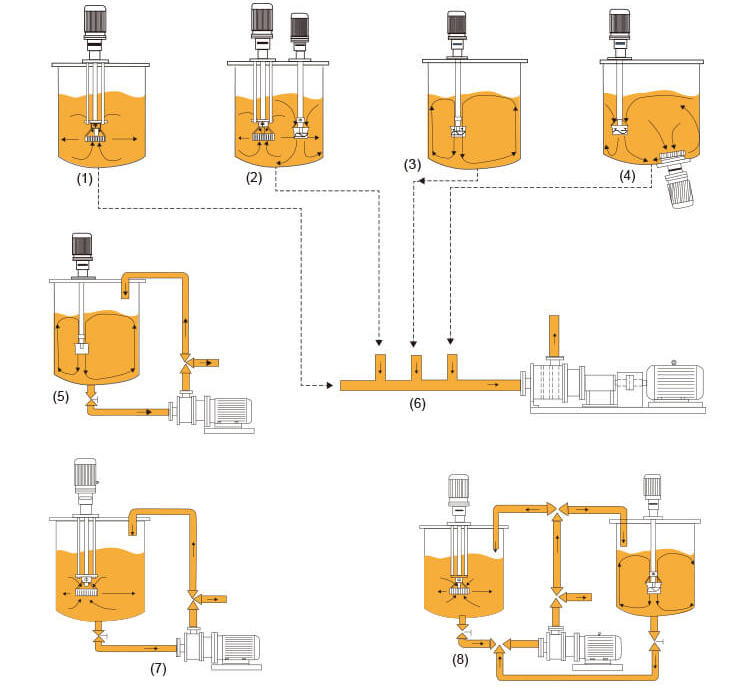

Common Structural Types

According to the characteristics of the materials and the user’s process requirements, we will choose the appropriate structural type and speed.

Combination And Collocation

Product detail pictures:

Related Product Guide:

Cooperation

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Reasonable price for 2000 Litre Conical Fermenter - High Shear Emulsifier Type III – Qiangzhong, The product will supply to all over the world, such as: Malta, Latvia, Brasilia, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.