Reasonable price for Soap Melter - Heating and Cooling Tank – Qiangzhong Detail:

Heating and Cooling Tank

PRODUCT STRUCTURE

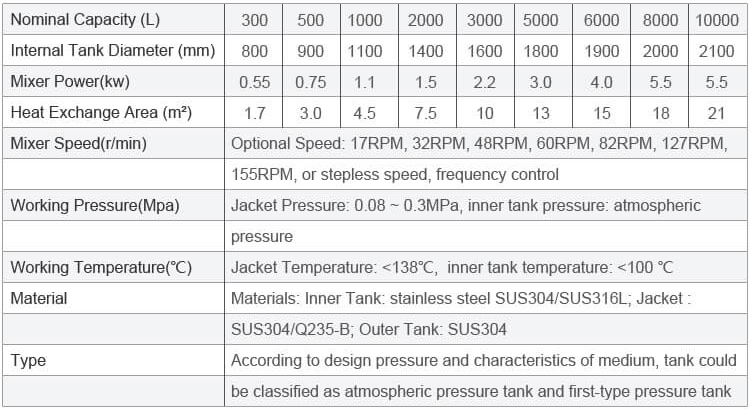

Steam Heating and Cooling Tank(with cover and mixer) SS304 Specifications

Optional Speed: 17RPM, 32RPM, 48RPM, 60RPM, 82RPM, 127RPM, 155RPM, or stepless speed, frequency control

Jacket Pressure: 0.08 ~ 0.3MPa, inner tank pressure: atmospheric pressure

Jacket Temperature: <138℃, inner tank temperature:

Materials: Inner Tank: stainless steel SUS304/SUS316L; Jacket : SUS304/Q235-B; Outer Tank: SUS304

According to design pressure and characteristics of medium, tank could be classified as atmospheric pressure tank and first-type pressure tank

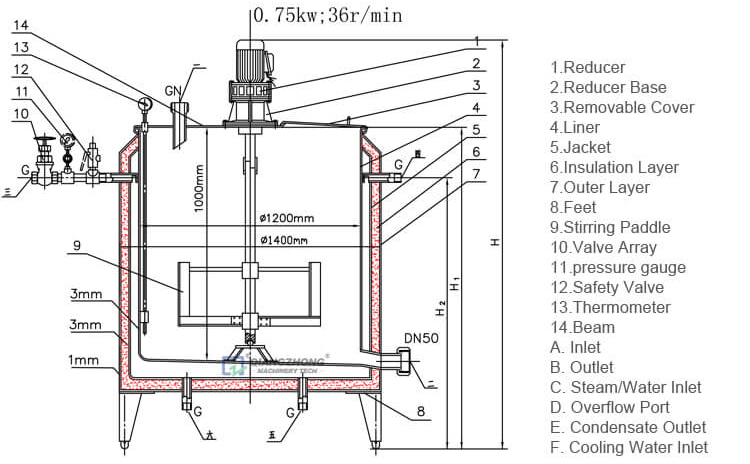

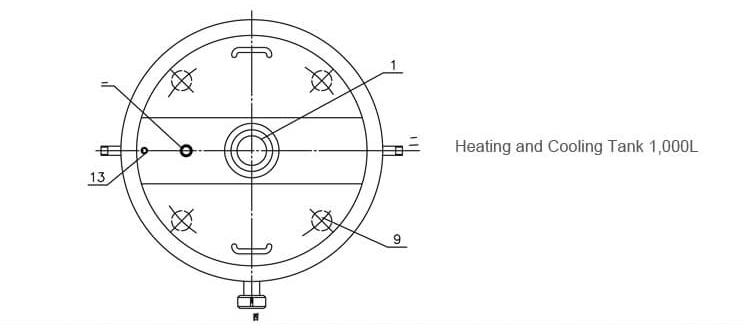

Heating and Cooling Tank 1,000L

| 1.Reducer | A. Inlet |

| 2.Reducer Base | B. Outlet |

| 3.Removable Cover | C. Steam/Water Inlet |

| 4.Liner | D. Overflow Port |

| 5.Jacket | E. Condensate Outlet |

| 6.Insulation Layer | F. Cooling Water Inlet |

| 7.Outer Layer | |

| 8.Feet | |

| 9.Stirring Paddle | |

| 10.Valve Array | |

| 11.pressure gauge | |

| 12.Safety Valve | |

| 13.Thermometer | |

| 14.Beam |

Note:

1. Power of stirring motor in the chart is for reference. Configurations of power of stirring motor, stirring speed and stirring paddle type depend on nature of processing materials.

2. Other requirements not listed in the diagram, such as volume, can be customized according to user requirements.

3 To determine best suitable batching tank, please provide such information including: nature of material, working pressure, working temperature, working conditions, and etc.

4.Attached technical documents: drawings (CAD) of structure and dimension, installation drawings, quality certificate, manual of installation and operation.

PRODUCT SHOWCASE

Product detail pictures:

Related Product Guide:

Cooperation

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Reasonable price for Soap Melter - Heating and Cooling Tank – Qiangzhong, The product will supply to all over the world, such as: Johannesburg, Lyon, Swedish, Due to our good products and services, we have received good reputation and credibility from local and international customers. If you need more information and are interested in any of our products, please feel free to contact us. We look forward to becoming your supplier in the near future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

Super Purchasing for Steam Wax Melter - Single...

-

Competitive Price for Used 3 Bbl Brewing System...

-

Cheap PriceList for 50l Fermenter - Mobile emu...

-

Good User Reputation for Food Mixing Tank - JM...

-

Wholesale Dealers of Membrane Filter Press - D...

-

Professional China Mixer Bucket - Electric lif...