Refrigerated Dispersion and Mixing Tank System

We specialize in manufacturing food and medical equipment, and know you better! Widely used in food, beverage, pharmaceutical, daily chemical, petroleum and chemical industries.

PRODUCT PARAMETERS

Refrigeration tank parameter list

|

Capacity(L) |

Compressor(P) |

Mixing Speed (r/min) |

Refrigerant Unit |

Refrigerant |

Size(L*W*H)(mm) |

|

300 |

2.5 |

36 |

SANYO COPLAND |

R-404a/R-22 |

1700x900x1550 |

|

500 |

2.5 |

36 |

1800x1000x1850 |

||

|

1000 |

3 |

36 |

1680x1210x1300 |

||

|

2000 |

5 |

36 |

2050x1500x1500 |

||

|

3000 |

6 |

36 |

2380x1700x1600 |

||

|

4000 |

8 |

36 |

2630x1800x1700 |

||

|

5000 |

10 |

36 |

2980x1900x1800 |

||

|

6000 |

12 |

36 |

3080x2100x1950 |

||

|

7000 |

12 |

36 |

3300x2100x1950 |

Dispersion tank parameter list

|

Capacity(L) |

Motor Power(kw) |

Tank Body(mm) |

Mixer Speed(r/min) |

Working Pressure |

Working Temperature |

|

100 |

2.2 |

550 |

2800 |

<0.09Mpa (atmospheric) |

<160 |

|

300 |

4.0 |

800 |

2800 |

||

|

500 |

5.5 |

900 |

2800 |

||

|

1000 |

7.5 |

1200 |

2800 |

||

|

2000 |

18.5 |

1400 |

2800 |

||

|

3000 |

22 |

1600 |

1400 |

||

|

5000 |

37 |

1800 |

1400 |

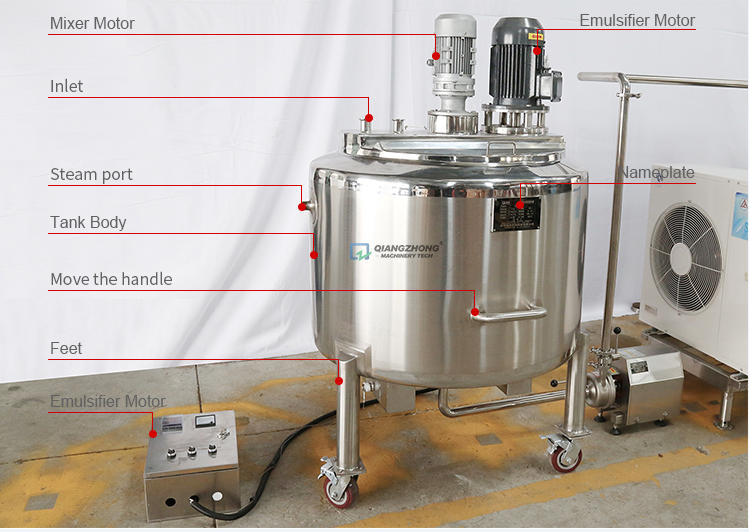

PRODUCT STRUCTURE

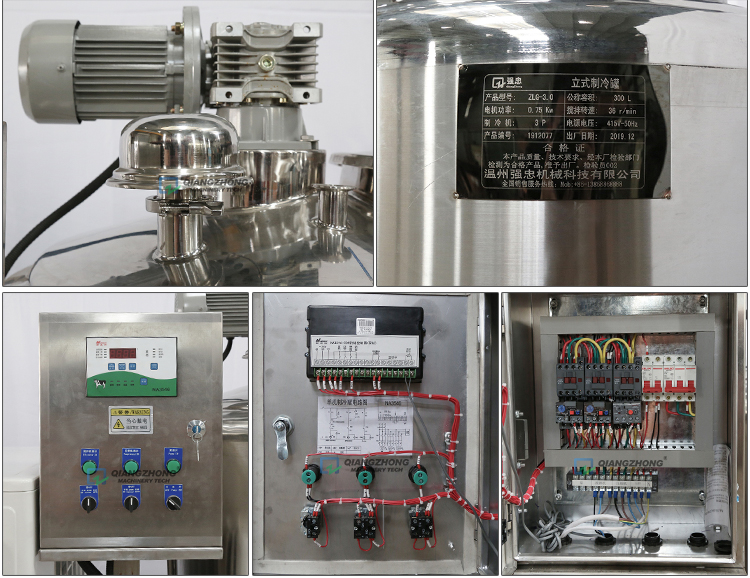

The refrigerated dispersion and mixing tank is made up tank body, agitator, refrigerating unit and control box. The tank body is made of stainless steel 304, and be minutely polished. Insulation is filled by polyurethane foam; light weight, good insulation properties.

Requirements before installation

•Must be careful when you carry it, do not tilt more than 30°to any position.

•Check the wooden case, make sure it is not damaged.

The refrigerating fluid has already been filled into the unit, so it is not allowed to open the valve of the compressor unit during transportation and and storage.

Location of work house

•The work house should be spacious and good air liquidity. There should be an one-meter passageway for operator working and maintain. When it is mechanized milking, you should consider about the connection with other equipment.

•The foundation of the tank should be 30-50 mm higher than the floor.

Installation of the tank

•After the tank got in position, please adjust the feet-bolts, make sure the tank tilt to the discharge hole, but not too much, just can discharge all the milk in the tank. You must make sure the six feet uniform stress, do not allow any foot be drift. You can adjust the left-right slope by Horizontal scale, make sure it is not slope to left or right.

•Switch on the inlet of condenser.

•The equipment switch on electric power must switch on the earth.

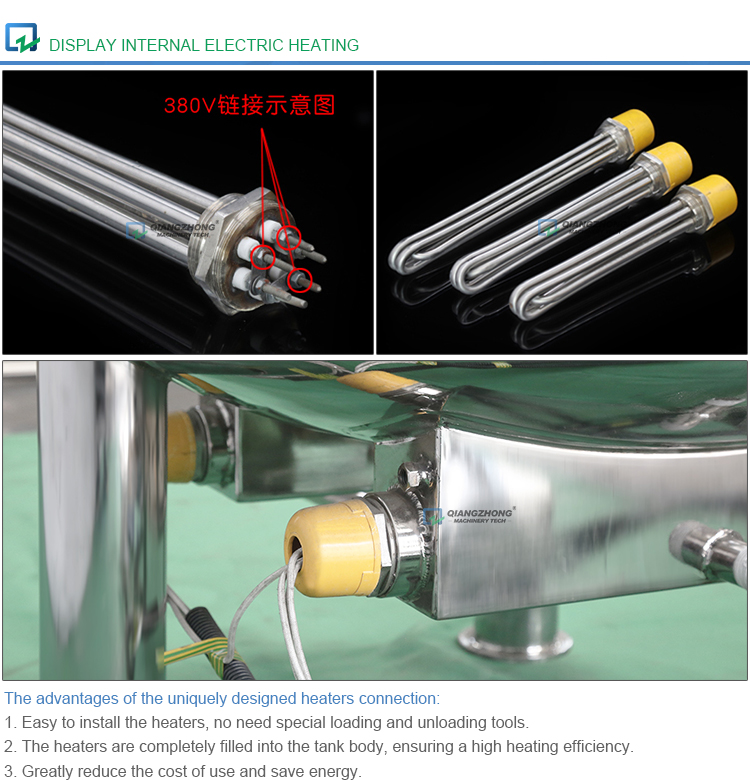

Stirring tank having energy dispersion, corrosion, production capacity, simple structure, and easy cleaning. Suitable for continuous production of high-performance homogenizer or loop processing apparatus needs stirring, dispersing, broken material. Air respirators, sight glasses, pressure gauges, manholes, cleaning balls, casters, thermometers, level gauges and control systems can be configured according to customer requirements.

•Mixing tank mainly consists of tank body, cover, agitator, supporting feet, transmission device and shaft seal device.

•Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel and other materials according to specific requirements.

•Tank body and cover can be connected by flange seal or welding. Also they could be with holes for purpose of feeding, discharging, observation, temperature measurement, manometry, steam fractionation and safety vent.

•Transmission devices (a motor or a reducer) are installed on top of the cover and the agitator inside the tank is driven by stirring shaft.

•Shaft sealing device can be used machine seal, packing seal or labyrinth seal, they are optional according to customer’s need.