Renewable Design for Vacuum Cooker For Hard Candy - Emulsification Tank – Qiangzhong Detail:

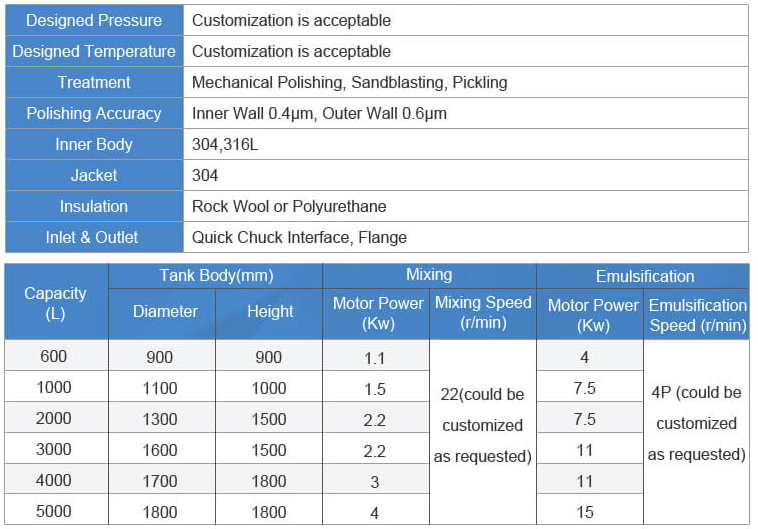

Product Parameters

Product Structure

Emulsification tank can dissolve one or more materials (water-soluble solid phase, liquid phase, or gums, etc.) in another liquid phase and make the water into a relatively stable emulsion. The homogenizer of the emulsifying tank can work together with the center blade mixer and wall scraper to form the best stirring method. The tank adopts a vertical round tank body and can be configured with a honeycomb jacket, a coil jacket or an integral jacket, which can be heated and cooled. The bottom of the tank can be inclined to facilitate venting. The material is stainless steel 304 or 316L.

Optional Configuration

Aseptic air filter, thermometer (digital or dial type), sight glass, sanitary hole, inlet and outlet holes, CIP swivel cleaning ball, sterile sampling valve (stainless steel tank bottom), liquid level gauge and liquid Automatic control system (load-bearing module, contactless ultrasonic, static pressure transmitter), etc., or configured according to customer requirements.

Product Features

● Compact structure, small size, light weight, easy operation, low noise, stable operation, its biggest feature is that it does not grind materials during production, and it combines high-speed shearing, mixing, dispersing and homogenizing.

● Appropriate diameter-to-height ratio design, energy saving, fast material-mixing, high efficiency of emulsification and homogenization.

● The inner wall is electrolytic mirror polished or mechanically polished. The outer wall adopts the structure of 304 full-welded heat preservation and the outer surface adopts mirror or matte treatment. All the inlet and outlet nozzles, sight glasses, manholes and other process openings and inner tank welding adopt flanging process arc transition, smooth and easy to clean without dead ends, ensuring the reliability and stability of production process, in line with GMP and other regulatory requirements.

● Capacity is available from 600L to 20,000L, and also could be customized in other capacities as requested.

Typical Application

Suitable for the production of industrial products such as cosmetics, medicine, food, chemistry, dyeing and printing ink, especially materials with large viscosity and high solid content.

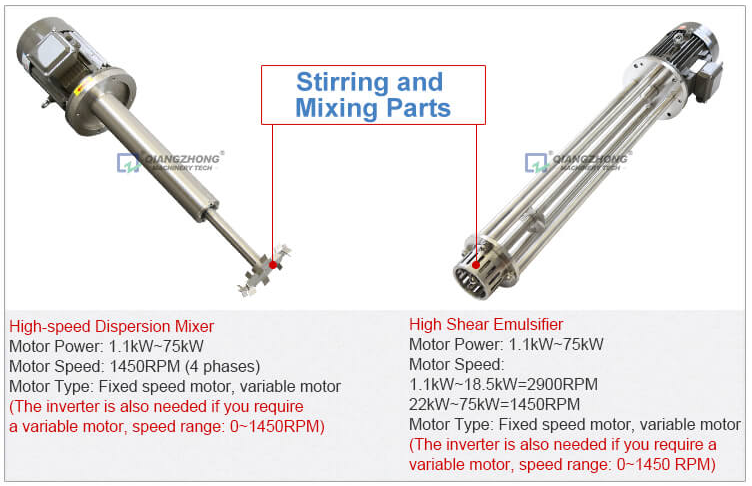

Stirring Paddle Type

Common Structure of the Stirring Paddle

We will select the appropriate stirring paddle type and stirring speed according to the characteristics of the mixing material and the user’s process requirements.

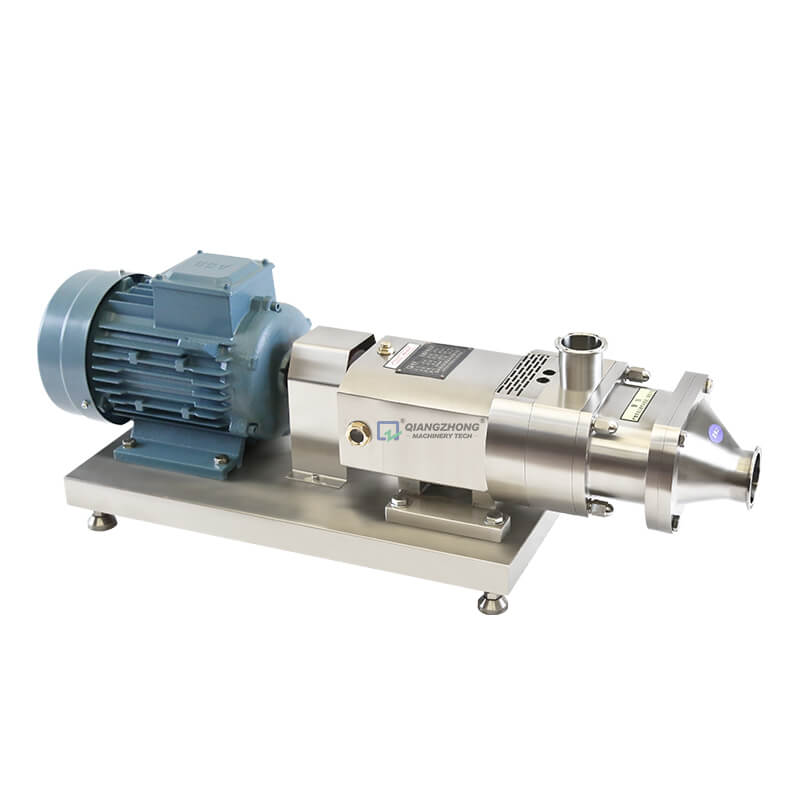

In addition to the above types of stirring paddles, some mixing tanks may also be equipped with a high shear emulsifier or a vane type dispersing mixer Its strong mixing force can quickly disperse and mix the materials.

Product detail pictures:

Related Product Guide:

Cooperation

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Renewable Design for Vacuum Cooker For Hard Candy - Emulsification Tank – Qiangzhong, The product will supply to all over the world, such as: Johannesburg, United Kingdom, Uruguay, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Wholesale Discount Filter Equipment - Air Filt...

-

Special Design for Mixing Container - Twin Scr...

-

Manufacturer of Fermentation Crock - JM-W Hori...

-

Chinese Professional Pectin Production Equipmen...

-

factory Outlets for Fuel Tank Storage - JM-F S...

-

OEM manufacturer Soap Grinding - Biological Fe...