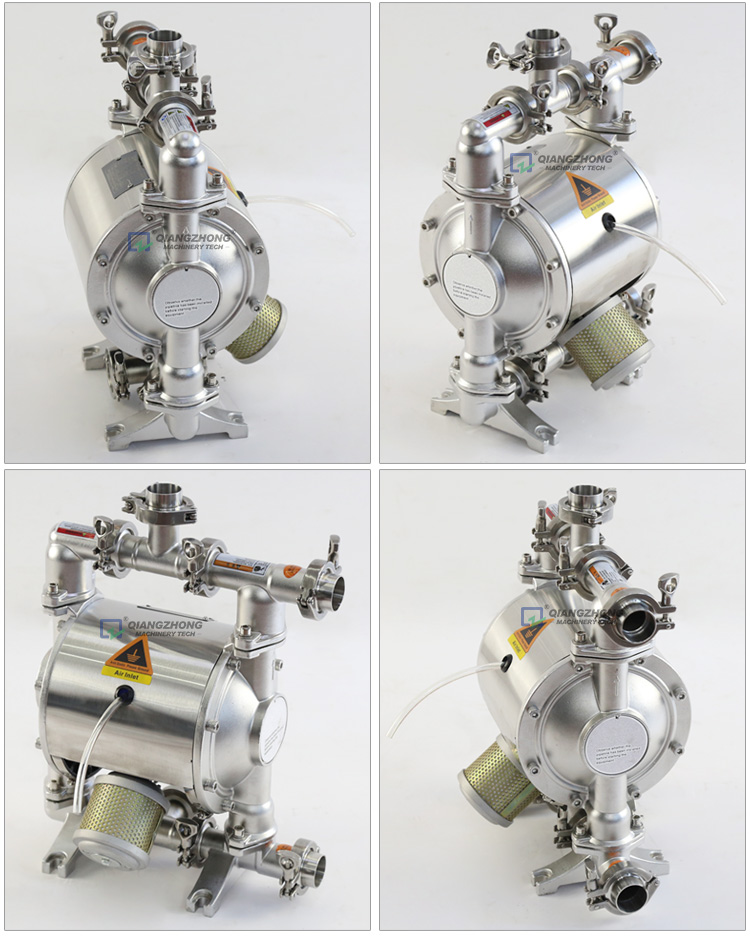

Sanitary Pneumatic Diaphragm Pump

Used in various special occasions to meet the needs of different users.It is used to pump media that cannot be pumped by conventional pumps and achieve satisfactory results.

Product Parameters

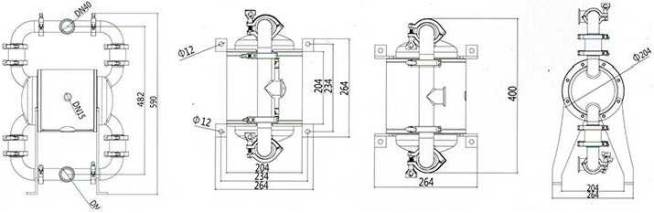

| Model No. |

Flow (T/h) |

Dia. (mm) |

Lift (m) |

Suction (m) |

Pressure Air Consumption Partical Dia. |

weight (kg) |

||

|

(mpa) |

(scfm) |

(mm) | ||||||

| QBSY5-20 | 0.1-1.8 |

20 |

0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-25 | 0.1-1.8 | 25 | 0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-32 | 0.1-6 | 32 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-38 | 0.1-6 | 38 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-51 | 0.1-12 | 51 | 0-50 | 5.48 |

0.75 |

32 |

5.5 |

33 |

| QBSY5-63 | 0.1-12 | 63 | 0-50 | 5.48 |

0.75 |

12.7 |

5.5 |

33 |

| QBSY5-76 | 0.1-22 |

76 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

| QBSY5-89 | 0.1-22 |

89 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

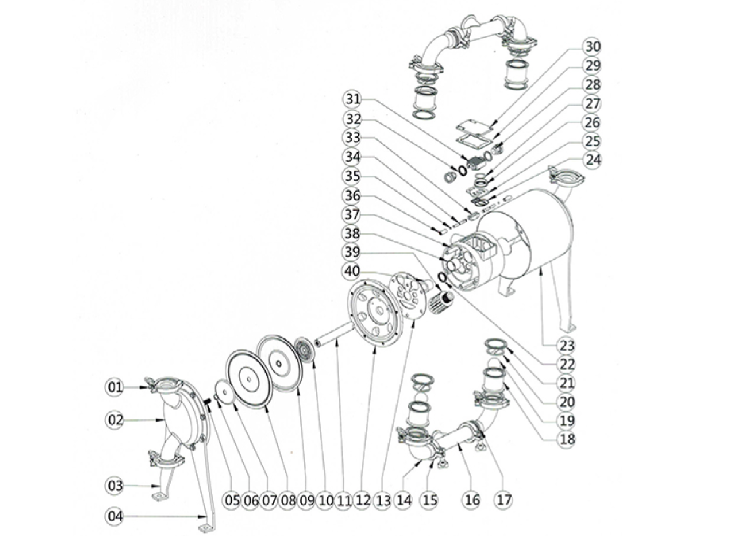

| 1. B Type Clamp | 11. Connecting Rod Shaft | 21. BType Seal | 31. Large Slider Aluminum Parts |

| 2. Column | 12. Rows | 22. V-Ring | 32. V Ring |

| 3. Left Foot | 13. Gas Valve Chamber Gasket | 23. Protective Cover | 33. Small Slider |

| 4. Right Foot | 14. Quick Loading | 24. Guide Block Gasket | 34. Boosting Rod |

| 5. Plywood Screws | 15. A Type Clamp | 25. Guide Block | 35. Boosting Rod O-Ring |

| 6. Splint O-Ring | 16. Inlet And Outlet Pipe | 26. Large Slide Plastic Parts | 36. Actuating Rod Cover |

| 7. Outer Splint | 17. A Type Sealing Ring | 27. Large Slider O-Ring | 37. Valve Chamber |

| 8. PTFE Membrane | 18. Ball Valve | 28. Pistons | 38. Piston Sleeve |

| 9. Poly Film | 19. Ball Valve | 29. Gas Valve Cover Gasket | 39. Silencer |

| 10. Inner Splint | 20. Ball Seat Cover | 30. Valve Cover | 40. Connecting Rod Sleeve |

Working Principle

Pneumatic diaphragm pump is a volumetric pump that brings volume change by reciprocating deformation of the diaphragm. Its working principle is similar to the plunger pump. Diaphragm pumps have the following features:

I -The pump will not be overheated: With compressed air as power, the exhaust is a process of expanding and absorbing heat, so during operation, the temperature of the pump itself is reduced and no harmful gas is discharged.

2-No spark generation: Pneumatic diaphragm pumps do not use electric power as a power source and can prevent electrostatic sparks after they are grounded.

3.lt can pass through the liquid containing particles: Because it uses a volumetric working method and the inlet is a ball valve, not easy to be blocked.

4. The shearing force is extremely low: the material is discharged in the same state as it is sucked in when the pump is at work, so the agitation of the material is minimal and it is suitable for conveying unstable substances.

5. Adjustable flow rate: A throttling valve can be installed at the material outlet to regulate the flow.

6.Self-priming function.

7.It can be idling without danger.

8.lt can work in diving.

9. The range of fluids that can be delivered is extremely wide ranging from low viscosity to high viscosity, from corrosive to viscous.

10. The control system is simple and uncomplicated, without cables, fuses, etc.

II .Small size, light weight, easy to move.

12.Lubrication is not required, so maintenance is simple and it does not cause contamination of the working environment due to dripping.

13.lt can always be efficient, and it will not reduce work efficiency due to wear.

14.100% energy utilization. When the outlet is closed, the pump stops automatically to prevent equipment movement, wear, overload, and heat generation.

15.There is no dynamic seal, maintenance is simple, leakage is avoided, and there is no dead point when working.