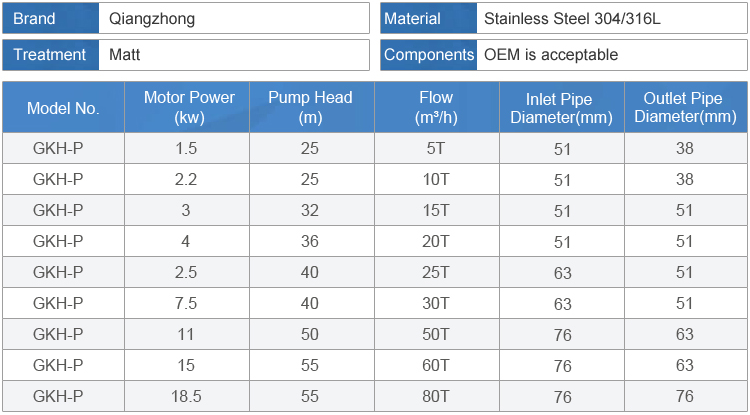

Note: models in capacities of 1T/h to 10T/h in this series could also be with single-phase and 220V (0.37kw-2.2kw) motors, and the rest only work with three-phase 380V motors. Please confirm the voltage and phase type with us before ordering.

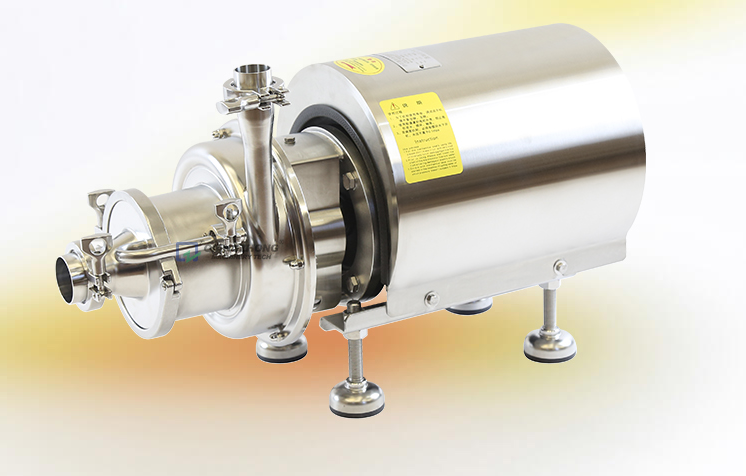

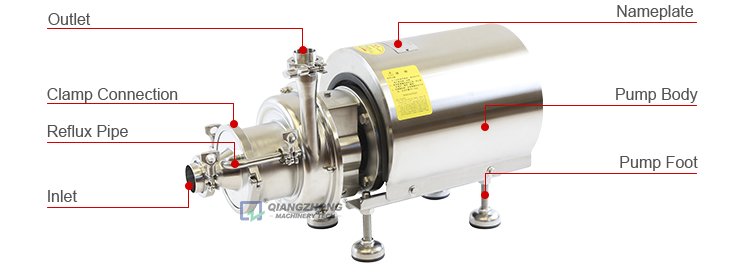

Product Structure

● The is mainly composed of a pump body, a pump base, and a motor part. Each part is connected by a bolt. The supporting feet of the base can be freely adjusted to facilitate installation without a fixed mounting base. The outlet pipe can be installed vertically or horizontally according to different needs.

● It adopts a smooth transition, rigid structure and thick-walled design. The parts including the pump body, pump cover, impeller part and the part in contact with the material are all made of stainless steel (AISI316 or AISI304). Mechanical shaft seals are made of high quality stainless steel and silicon carbide. Greatly improved wear resistance and moisturization, extending the useful life.

● The pump body and the impeller adopt the integral precision casting and surface of all parts are treated. With special fixtures to assist installation, ensuring an accurate dimensional clearance. The shaft seal adopts the open type structure, so even a small amount of leakage at the shaft seal can be observed in time. It also ensures that even if the leakage is not noticed within a short time, it will not overflow in the motor, thus ensuring a good service life of the motor.

Working Principle

The self-priming pump is specifically designed to process sucked materials at a lower liquid level than the pump inlet, and to deliver fluid materials containing some gas. Due to the centrifugal force of the self-priming pump impeller rotating, the gas-liquid mixture is thrown out continuously and flows along the volute of the self-priming pump. Since the gap between the pump tongue of the self-priming pump and the impeller is very small, the mixed liquid acts as a barrier, so a considerable part of the mixture is sent along the inner channel to the drain port. At the discharge port, there is a gas-water separation chamber with a large cross section. After the liquid mixture enters the air-water separation chamber, the flow rate will slow down. Due to the differences in the specific gravity of the gas and the liquid, the lighter gas is separated and discharged from the discharge pipe and the exhaust pipe. The degassed medium flows back to the impeller inlet along the outer channel of the pump body due to its large specific gravity, and it is re-involved in air to form a mixed liquid. After several cycles, the air in the inlet pipe of the self-priming pump can be discharged after a certain period of time to reach a certain degree of vacuum. At this time, under the action of liquid surface atmospheric pressure and the negative pressure in the pump, the liquid is sucked into the liquid inlet tube, and the self-priming pump absorbs water. After the self-priming process is completed, it is automatically converted to the transport process and the media is output continuously. When the water is normally discharged, both the internal and external channels of the self-priming pump automatically change to the water supply channel.

Product Showcase

Q & A

Q1: What is the lift and flow of this pump?

A1: The lift and flow of this pump is based on motor power. You can tell us your required flQ2: What is the motor brand?

A2: The brand of non-explosion-proof motor is Dedong, and the explosion-proof motor brand is HuXin. If customers require other brands of motor, such as ABB, Siemens, etc., we can also customize it.

Q3: What is the connection type of the pump?

A3: There are three connection types, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection.

Q4: What is concentration of the materials that can be conveyed by the pump?

A4: The highest concentration is 0.4. Generally, the liquid can be transported as long as it can flow automatically.

Q5: What is the maximum working temperature of the pump?

A5: The maximum working temperature is 150 degrees Celsius, and both double seals and water cooling should be used when it is above 100 degrees Celsius.

Q6: Is there any explosion-proof motor and variable frequency motor available?

A6: Yes, the explosion-proof motor or variable frequency motor is available according to customers’ requirement, but the standard motor is non-explosion-proof and non-variable frequency motor.

Q7: What is the material of the pump?

A7: The standard material is 304 stainless steel, and if require 316L stainless steel please advise us before placing the order.

Q8: What is the motor voltage?

A8: The standard voltage in China is 3 phase/380v/50hz, and if any other voltage is required, please check with us before order confirmation.

Installation Instructions

Installation Method and Place:

It is very necessary to check the following before installation:

◎The drive is in good condition.

◎Whether the on-site power supply is the same as the rated power on the motor nameplate.

◎Whether it meets the environmental conditions (avoid flammable and explosive environment or acid corrosion environment).

Installation Location:

The installation foundation of the pump should generally be level and sufficient-strengthened ground. Install it as far as possible on the lowest position of the equipment, that is, at the position with the maximum head height.

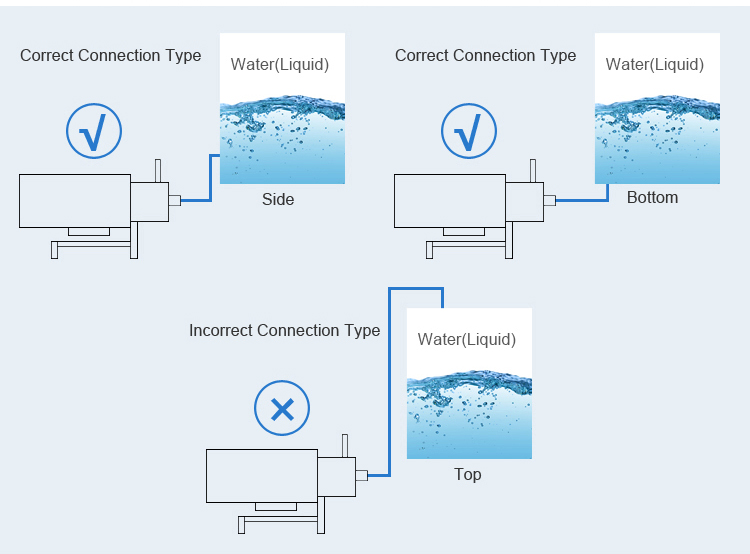

Piping Installation:

The diameter of pump、 pipe and the inlet and outlet of the pump should be the same, and the diameter of the inlet pipe should not be too small. When the diameter of the pipe is smaller than the diameter of the pump, adjust it with an eccentric reducer to shorten the diameter of the pipe so as to avoid formation of a gas leak. The outlet pipe diameter must not be too large either. When the outlet pipe diameter is larger than the pump outlet, try to extend it. Distance from the pump outlet to avoid overloading the pump motor.