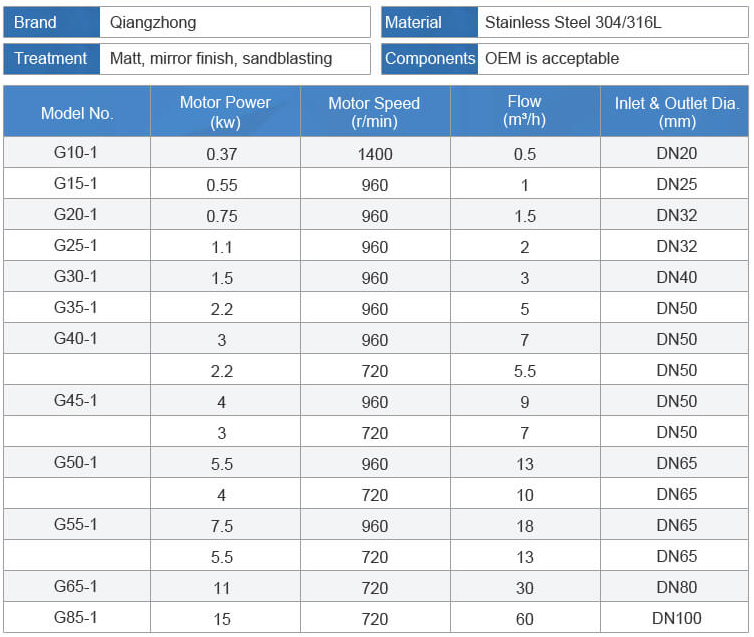

Product Parameters

Product Introduction

The screw pump sucks and discharges liquid by means of screw rotation. The middle screw is the active screw, which is driven by the prime mover. The screws on both sides are the driven screws, and they rotates in reverse with the active screw. Both the active and driven screw threads are double-ended. Due to the intermeshing of the spiral and the close fit of the spiral with the inner wall of the liner, a series of multiple sealed spaces are formed between the suction inlet and the discharge outlet of the pump. With the rotation and engagement of the screw, a continuous seal space is formed at the suction end of the pump, the liquid in the suction chamber is sealed therein, and is continuously pushed along the suction chamber to the discharge end in a spiral axial direction. It continuously and smoothly discharges the liquid enclosed in the separate spaces, as if the nuts were continuously pushed forward while the spiral was rotating. This is the basic working principle of this series of double screw pump.

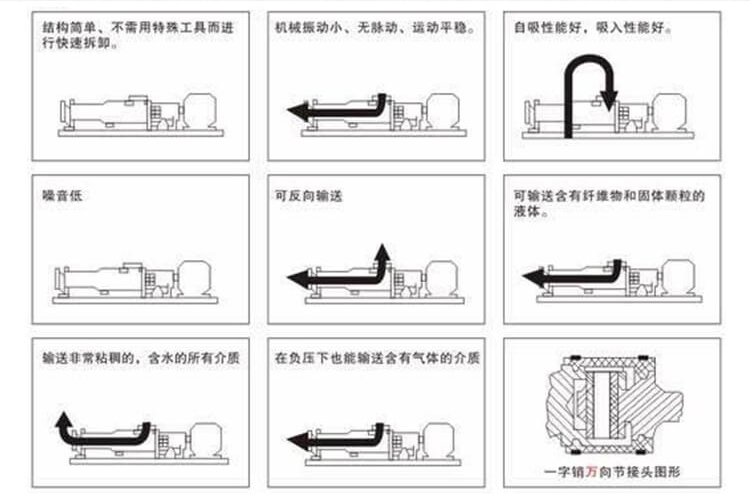

Screw Pump Features:

1. The spiral seal line in contact with the rotor of the stator completely separates the suction chamber from the discharge chamber, so that the pump has the same function as a valve;

2. It can deliver the multi-phase media of liquid, gas and solid.

3. The volume does not change when the fluid in the pump flows, there is no turbulent stirring and pulsation;

4. The volume chamber formed by the elastic stator can effectively reduce the wear of the medium containing solid particles;

5. The input medium viscosity up to 50,000Mpa·s, solids up to 50%;

6. The flow rate is proportional to the speed, and with the governor, it can automatically adjust the flow, and both forward and backward delivery are allowed.

The screw pump has the following advantages:

● Compared with the centrifugal pump, the screw pump does not need to install the valve, and the flow rate is a stable linear flow;

● Compared with the plunger pump, the screw pump has strong self-priming ability and higher suction height;

● Compared with the diaphragm pump, the screw pump can transport all kinds of mixed impurities, such as medium containing gas and solid particles or fibers, and it can also transport various corrosive substances;

● Compared with gear pumps, screw pumps can deliver highly viscous media;

● Unlike piston pumps, diaphragm pumps and gear pumps, screw pumps can be used for filling and metering pharmaceuticals.

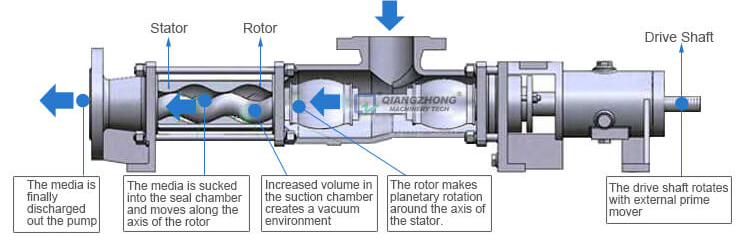

Working Principle

The screw pump is a push-type displacement pump. The main components are a rotor and a stator. The rotor is a large-lead, large-tooth-height, and small-helix internal-diameter screw, and the stator is a matched double-headed spiral and sleeve, which forms a space for the storage medium between the rotor and the stator. When the rotor is operating in the stator, the medium moves axially from the suction end to the discharge movement.

The screw pump has the following advantages:

1.A wide range of pressure and flow. The pressure is about 3.4-340 kgf/cm² and the flow rate is 1,8600 cm³/m;

2. Wide range of types and viscosities of deliverable liquids;

3. It has a high speed because of the low inertia force of the rotating parts in the pump

4. With self-priming ability, good suction performance,;

5. Uniform flow, low vibration, low noise;

6. Less sensitive to the incoming gas and dirt compared with other rotary pumps,

7. A solid structure, easy installation and maintenance.

The disadvantage of the screw pump is that the screw requires high processing and assembly; the performance of the pump is sensitive to changes in the viscosity of the liquid.

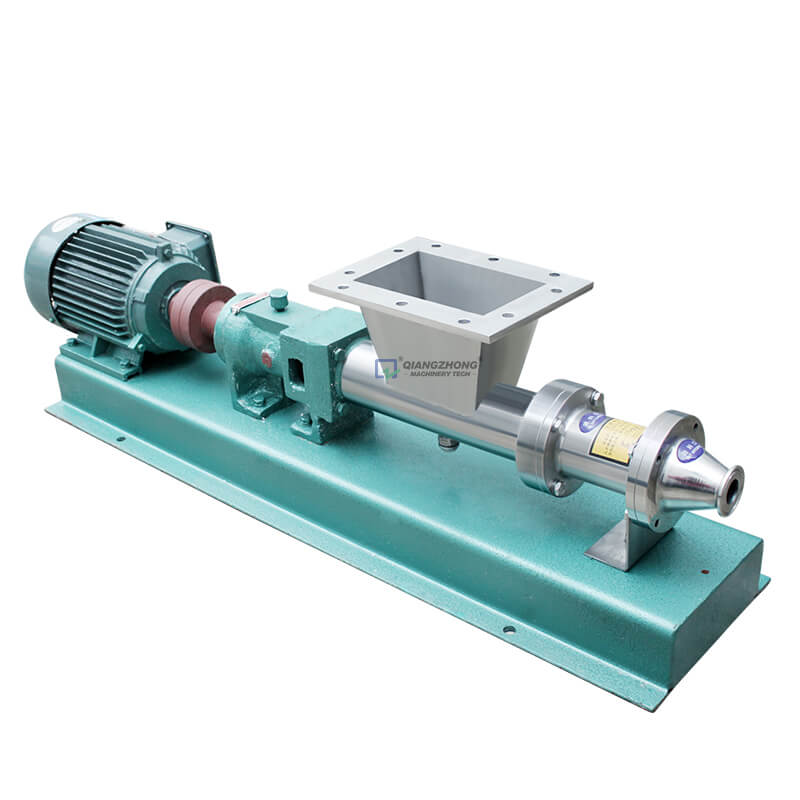

Product Showcase

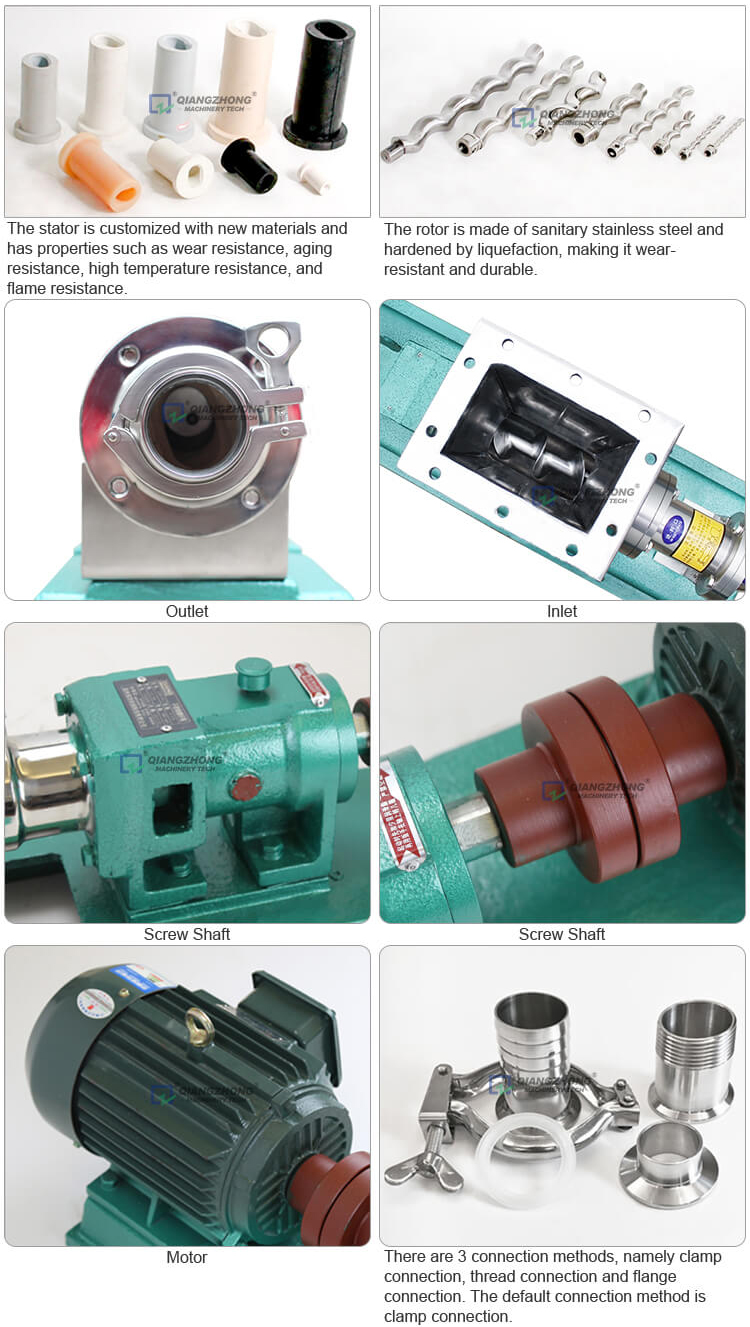

The stator is customized with new materials and has properties such as wear resistance, aging resistance, high temperature resistance, and flame resistance.

The rotor is made of sanitary stainless steel and hardened by liquefaction, making it wear-resistant and durable.

There are 3 connection methods, namely clamp connection, thread connection and flange connection. The default connection method is clamp connection.

Common Faults and Solutions

1.The pump does not work:

Possible causes: The rotor and stator are too tight; the voltage is too low; the viscosity of the medium is too high.

Solution: Rotate the pump a few times with tools and by manpower; adjust the pressure; dilute the media.

2. The pump does not flow out:

Possible causes: wrong direction of rotation; problems with the suction tube; too high viscosity of the medium; the rotor, stator, or transmission components were damaged;

Solution: Adjust the direction of rotation; check for leaks, open inlet and outlet valves; dilute media; inspect and replace damaged parts;

2.Lack of flow:

Possible causes: leaking pipes; valves not fully open or partially blocked; low working speed; wear of rotors and stators.

Solution: Check and repair pipelines; open all gates, remove plugs; adjust speed; replace damaged parts

4.Lack of pressure:

Possible causes: Worn rotor and stator.

Solution: Replace the rotor, stator

5.Motor overheating:

Possible causes: motor failure; excessive outlet pressure, motor overload, and motor bearing damage.

Solution: Check the motor and troubleshoot it; change the opening valve adjustment pressure; replace the damaged part.

6.Flow pressure drops sharply:

Possible causes: Sudden blockage or leakage of the circuit; serious wear of the stator; sudden change in viscosity of the liquid; sudden drop in voltage.

Solution: Remove plugged or sealed tubing; replace stator rubber; change fluid viscosity or motor power; adjust voltage.

7. A large number of leaking liquid at the shaft seal:

Possible causes: soft filler wear

Solution: Press or replace the filler .

Installation Instructions

● Pay attention to the rotation direction of the motor to prevent reverse rotation.

● An easy-to-remove pipeline with a length slightly larger than the stator should be installed before the liquid outlet to facilitate the replacement of the stator.

● Keep the pump inlet in the vertical direction, the outlet in the horizontal direction, so that the seal can work in the pressure state, reducing the pressure of the sealed chamber. Rotation: counterclockwise rotation as seen from the exit. The piping should be set up to support points, because the pump’s inlet and outlet flanges (pipes) cannot withstand the pipe weight.

●The pipeline must be cleaned before installation to prevent foreign objects from damaging the stator and rotor and causing blockage.

●The diameter of the pipeline should be matched with the diameter of the pump as much as possible. Too small inlet diameter will cause insufficient supply of the pump, which will affect the pump discharge and output pressure. In severe cases, it will lead to the vibration of the pipeline and early damage of the stator. Too small outlet pipe diameters will result in loss of outlet pressure.

● For shaft seals with mechanical seals, add fresh water, lubricating oil, or other coolant.

For single-ended sealed shaft seals, if the medium being delivered is a viscous, easily solidified and crystallized medium, the mechanical seal should be cleaned after the pump stops working to ensure the normal operation of the mechanical seal. Each side of the seal box has an inch pipe thread interface, and an outlet throttling fitting is also included. The inlet line of circulating fluid is directly connected to the seal box. On its outlet side, an outlet throttling fitting (which is critical for maintaining a certain pressure in the sealability box) is then connected to the outlet line. When starting the machine, the circulating fluid should be started first, then turn on the pump; when stopping, the pump should be stopped first, and then turn off the circulating fluid.