Dosing Tank / Batching Tank (mechanical mixing)

PRODUCT DESCRIPTION

The dosing mixing tank is a mixing container for mixing one or more materials according to the process ratio. It is manufactured and inspected according to pharmaceutical sanitary standards in the pharmaceutical industry.

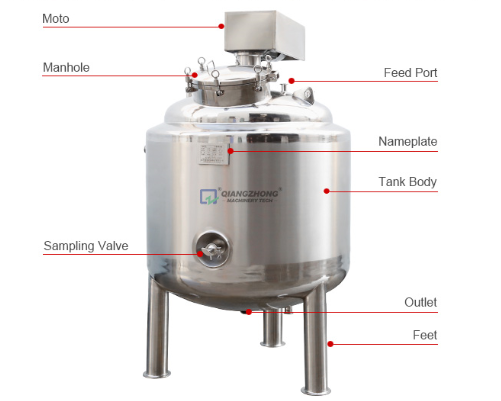

It has reasonable design and advanced technology, which fully meets the national GMP certification requirements. The tank body adopts a vertical double-wall structure, and the polishing accuracy of the inner tank is Ra 0.45. The inner cylinder is heated by winding a spiral belt and filled with polyurethane material for heat preservation. The exterior is insulated with a mirror panel or a frosted board, and the tank body has a consistent gloss. All parts in contact with the liquid chemical are made of 316L, and the rest are made of 304. The bottom head of the inner tank is concave-convex type, adopting partial-wall axial flow stirring. The top of the tank has water inlet, return port, disinfection port, CIP cleaning ball, filling port, and respirator port with 0.22um air respirator and stirring system. The bottom of the tank is provided with a condensate port, a discharge port, a sewage port, a sampling port, a temperature probe, and a liquid level sensor. It is equipped with a control cabinet, the meter displays the temperature and level of the liquid medicine, and provides upper and lower limit alarm functions. According to user requirements, a nitrogen filling device and a pH meter can be added to the tank.

Structural Features

It is the combination of upper and lower elliptical heads and honeycomb jackets. The reducer adopts horizontal worm gears. It has small interlayer space, forced circulation, large heating area, high efficiency, high compressive strength, and saves time than ordinary interlayer and coil sections , beautiful appearance, etc. The disadvantage is that there is a lot of welding, complicated process and high technical content. The reducer is a worm gear horizontal reducer, which can reduce the height by about 250-330mm compared to a vertical differential reducer.

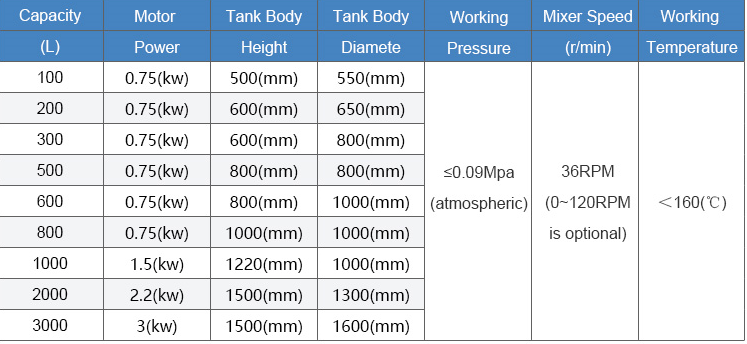

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

* the above table is for reference only, can customize according to customer’s requirements.

* this equipment can customize according to customer’s material, need to comply with process, such as meet high viscosity, homogeneous function strengthen, heat-sensitive materials such as requirements.

WORKING PRINCIPLE

1. Reducer: domestic/overseas brand

2. Sterile air filter: filter out bacteria >0.01 pm

3. Leak-proof device: degree up to 100%

4. Level gauge port: static pressure digital display sensor, ultrasonic, or glass tube positioning

5. Thermometer port: digital display temperature sensor, flow card, clamp type thermometer

6. CIP port: 360 degree rotation under 0.2mpa working pressure

7. Liquid inlet and outlet: quick-loading manhole

8. All GMP verification materials (including material report, purchased parts certificate, verification form, etc.)