General Technology

GB/T19228.2-2011

General technical requirements for stainless steel tube

GB/T19228-2011 is based on GB/T12771-2008, so the following technical requirements also apply to other general-purpose stainless steel tube.

Ⅰ. Size and Tolerance

Roundness: outer diameter allowable deviation C is ±0.5% D, DN150-300, 0.75% D below DN150;

Thickness: Allowable deviation: ±10%S;

Length: 3000-9000mm, also could be customized as required, allowable deviation: 0 ~ +20 mm;

Bending Degree: 2mm/M;

Slope: The slope of the steel pipe port should meet the requirements in the following table.

Ⅱ. The Weight Calculation Method

The stainless steel tube is generally delivered according to theoretical weight, and it can also be delivered according to actual weight after negotiation. When delivered according to theoretical weight, the theoretical weight is calculated according to formula (I)

| Stainless Steel Seal And Theoretical Weight Formula | |||||

| No. | New Grade | Old Grade | Density | Converted Formula | |

| 1 | 06Cr19Ni10 | 0Cr18Ni9 | 7.93 | W=0.024 91S(D-S) | |

| 2 | 022Cr19Ni10 | 00Cr19Ni10 | 7.90 | W=0.024 82S(D-S) | |

| 3 | 06Cr17Ni12Mo2 | 0Cr17Ni12Mo2 | 8.00 | W=0.025 13S(D-S) | |

| 4 | 022Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | 8.00 | W=0.025 13S(D-S) | |

| 5 | 019Cr19Mo2NbTi | 00Cr18Mo2 | 7.77 | W=0.024 35S(D-S) | |

| Slanting of Stainless Steel Tube Port | |

| Outer Diameter of the Tube | 切斜≤ Slanting≤ |

| ≤20 | 1.5 |

| >20-50 | 2.0 |

| >50-108 | 3.0 |

w=π‰S(D-S)ρ……………….(1)

Note:

W—the theoretical weight of the steel tube in kilograms per meter (kg/m);

Π = 3.1416;

S—the nominal wall thickness of the steel tube, in millimetres (mm);

D—The nominal outside diameter of the steel tube, in millimeters (mm):

P - Density of stainless steel in kg/dm3, please check the following table for density of each grade.

| Technical Requirements | |||

| The material grade and applicable conditions of the steel tube should meet the following requirements | |||

| No. | New Grade | Old Grade | Applicable Conditions |

| 1 | 06Cr19Ni10 | 0Cr18Ni9 | |

| 2 | 022Cr19Ni10 | 00Cr19Ni10 | Drinking purified water, daily drinking water, air, medical gas, cold water, hot water, etc. |

| Drinking purified water, cold water, hot water, etc. | |||

| 3 | 06Cr17Ni12Mo2 | 0Cr17Ni12Mo2 | |

| 4 | 022Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | Applications requiring higher corrosion resistance than 06Crl9NilO |

| 5 | 019Cr19Mo2NbTi | 00Cr18Mo2 | Applications requiring higher corrosion resistance than 06Cr17Ni12Mo2 |

Applicable environment with higher oxygen ions in the medium

| Grade and Chemical Composition of Stainless Steel Tubes (Smelting Analysis) | ||

| No. | Unified Digital Code | Chemical Composition (Mass Fraction)/% |

| The mechanical properties of the steel pipe should meet the requirements in the following table。 |

Specified Non-Proportional Extension Strength

Tensile Strength Rm/Mpa

Elongation After Fracture A/%

Heat Treatment Status

Non-Heat Treatment Status

Product Showcase

Product Case

Description

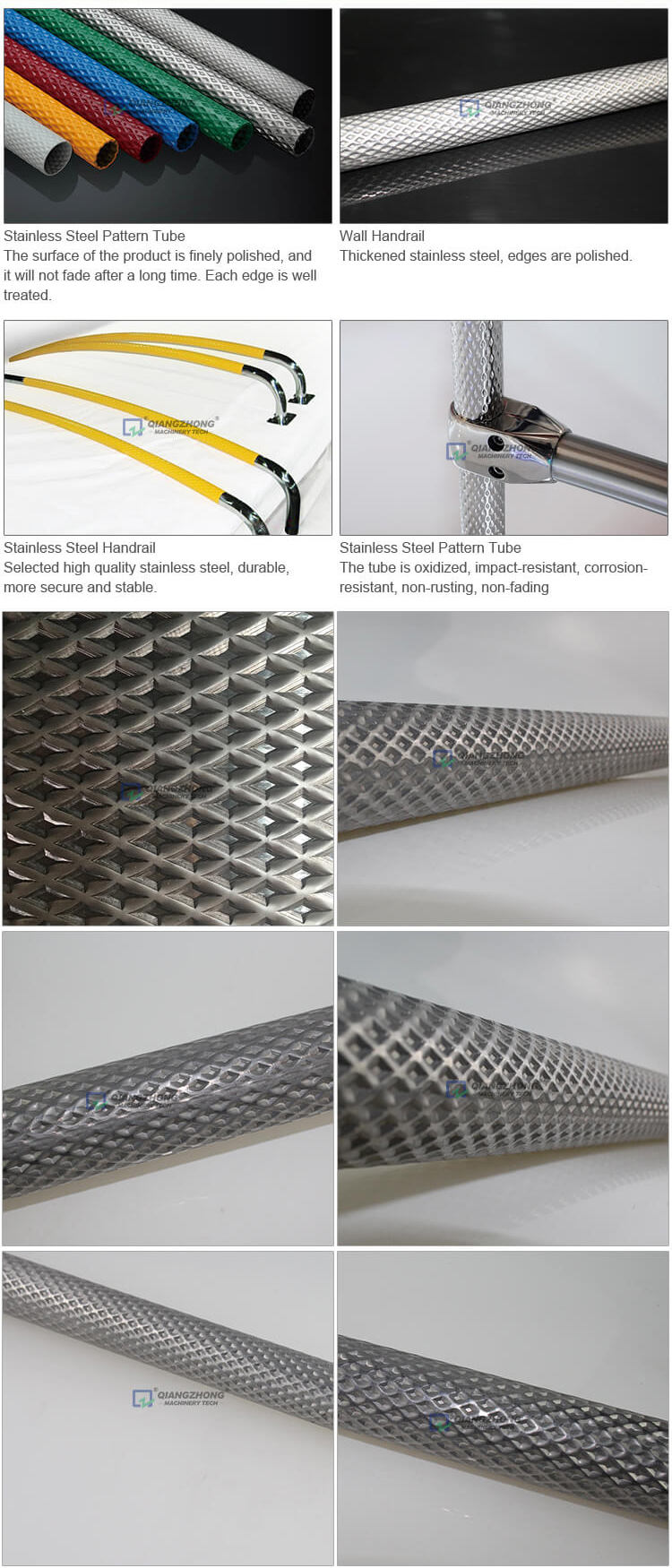

Stainless Steel Pattern Tube

- The tube is mainly welded tube or pattern tube, generally used as handrails or decoration, whose material is generally 304 stainless steel or better. Its production process is that first pressing pattern tube by steel strip, and then overall molding welding, and finally pickling and polishing.

- It is generally diamond pattern or circular pattern, adopting steel strip embossing and steel coil forming welding.

Its diameter is generally 22mm-48mm, main application: home decoration, staircase barricade handrails, pipe handles, car handrails, etc.

| φ25 x 1.5φ32 x 1.5 | Car, Bus |

| φ30 x 2.0 | Japan |

| φ32 x 2φ32 x 2.5 | China |

| φ35 x1.5φ35 x 2.0 φ35 x 2.5 φ35 x 3.0 |

Hong Kong, South Korea |

| φ38 x 2.0φ38 x 2.5 φ38 x 3.0 |

EU |

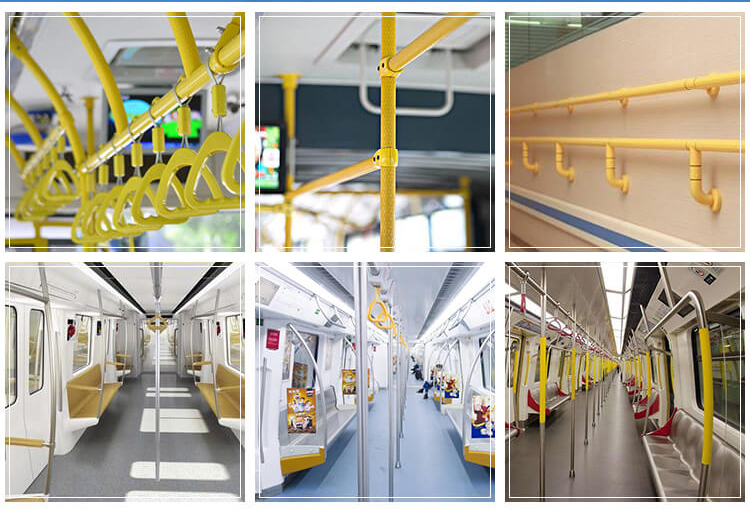

Stainless Steel Handrail Tube, Wall Handrail Tube, Handrail Tube for the Handicapped

This product has a novel structure and leading technology. According to the characteristics of the handrail, the organic combination of the casting and the pipe ensures that the handrail has high strength and smooth surface lines. The handrail splicing process solves the problem that some corners after handrail welding cannot be surface treated. According to the technical requirements, the surface of the handrail can be treated with brush, sand blasting, knurling, spray painting, and spray molding. Subsequently, the surface is treated in special anti-pollution process, making it beautiful appearance, free of oil and easy to clean. The special welding process for making the handrail is all-round monitored from the aspects of operation, equipment, and process parameters to ensure the welding quality.

| φ25 x 1.5φ32 x 1.5 | Car, Bus |

| φ30 x 1.2 | Japan |

| φ32 x 2φ32 x 2.5 | China |

| φ35 x 2.0φ35 x 2.5 φ35 x 3.0 |

Hong Kong, South Korea |

| φ38 x 2.0φ38 x 2.5 φ38 x 3.0 |

EU |