Top Quality Beef Cooker - Circulating emulsification mixing tank – Qiangzhong Detail:

Circulating Emulsification and Mixing Tank

Widely used in industries of brewery, dairy products, beverage, daily chemicals,bio-pharmaceuticals, etc. Mix, disperse, emulsify, homogenize, transport, batch

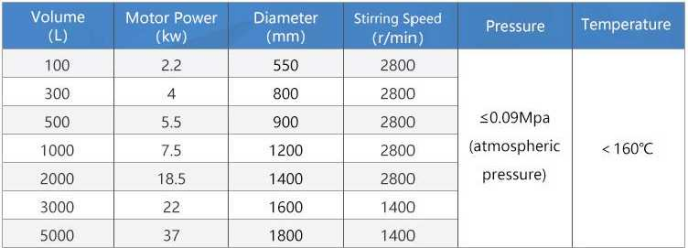

PRODUCT PARAMETERS

Technical file support: random provide equipment drawings (CAD), the installation drawing, the product quality certificate, installation and operating instructions, etc.

This tank is capable of distributing one or more phases to another continuous phase efficiently, quickly and uniformly, in which case the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction and impact in the narrow gap between the stator and the rotor. A combination of tearing and turbulence. Therefore, the incompatible solid phase, the liquid phase, and the gas phase are uniformly and finely dispersed and emulsified under the action of the corresponding mature process and an appropriate amount of additives, and the high-frequency cycle reciprocates to finally obtain a stable high-quality product.

•The mixing tank mainly consists of tank body, cover, agitator, supporting feet, transmission device, shaft seal device, etc.

•Tank body, cover, agitator and shaft seal can be made of carbon steel, stainless steel or other materials according to specific requirements.

•The tank body and the cover can be connected by flange seal or welding. Also they could be with ports for purpose of feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, safety vent. etc.

•The transmission device (a motor or a reducer) is installed on top of the cover, and it can drive the agitator inside the tank is by stirring shaft.

•The shaft seal can be used mechanical seal, packing seal or labyrinth seal as requested.

•The agitator type could be impeller, anchor, frame, spiral type. etc. according to the requirements of different application.

Common Structure of the Stirring Paddle

We will select the appropriate stirring paddle type and stiuing speed according to the characteristics of the mixing material and the user’s process requirements.

In addition to the above types of stirring paddles, some mixing tanks may also be equipped with a high shear emulsifier or a vane type dispersing mixer. Its strong mixing force can quickly disperse and mix the materials.

Product detail pictures:

Related Product Guide:

Cooperation

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Top Quality Beef Cooker - Circulating emulsification mixing tank – Qiangzhong, The product will supply to all over the world, such as: Norwegian, Sao Paulo, Los Angeles, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

-

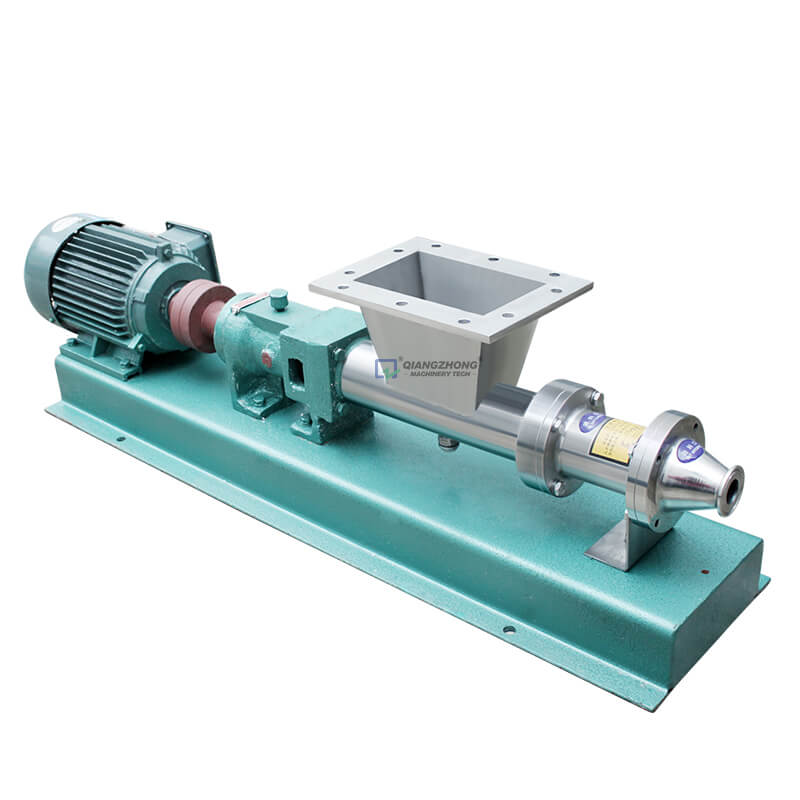

factory Outlets for Stainless Steel Screw Pump ...

-

Reliable Supplier Electric Coffee Maker - Elec...

-

Discount wholesale Emulsifying Machine - New T...

-

China Cheap price Millipore Filter Housing - E...

-

100% Original Factory Beer Brewing 500l - High...

-

OEM/ODM Factory Pilot Fermenter - JM-F Split C...