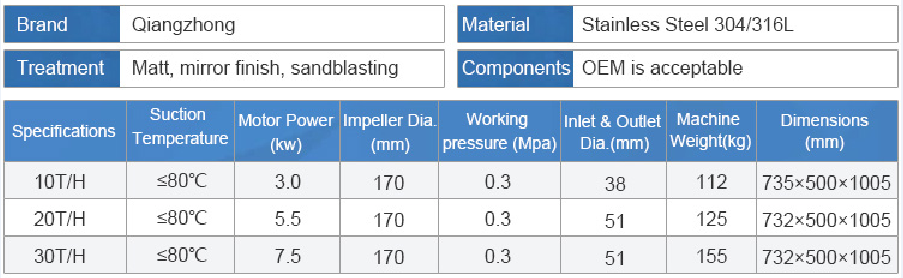

PRODUCT PARAMETERS

PRODUCT STRUCTURE

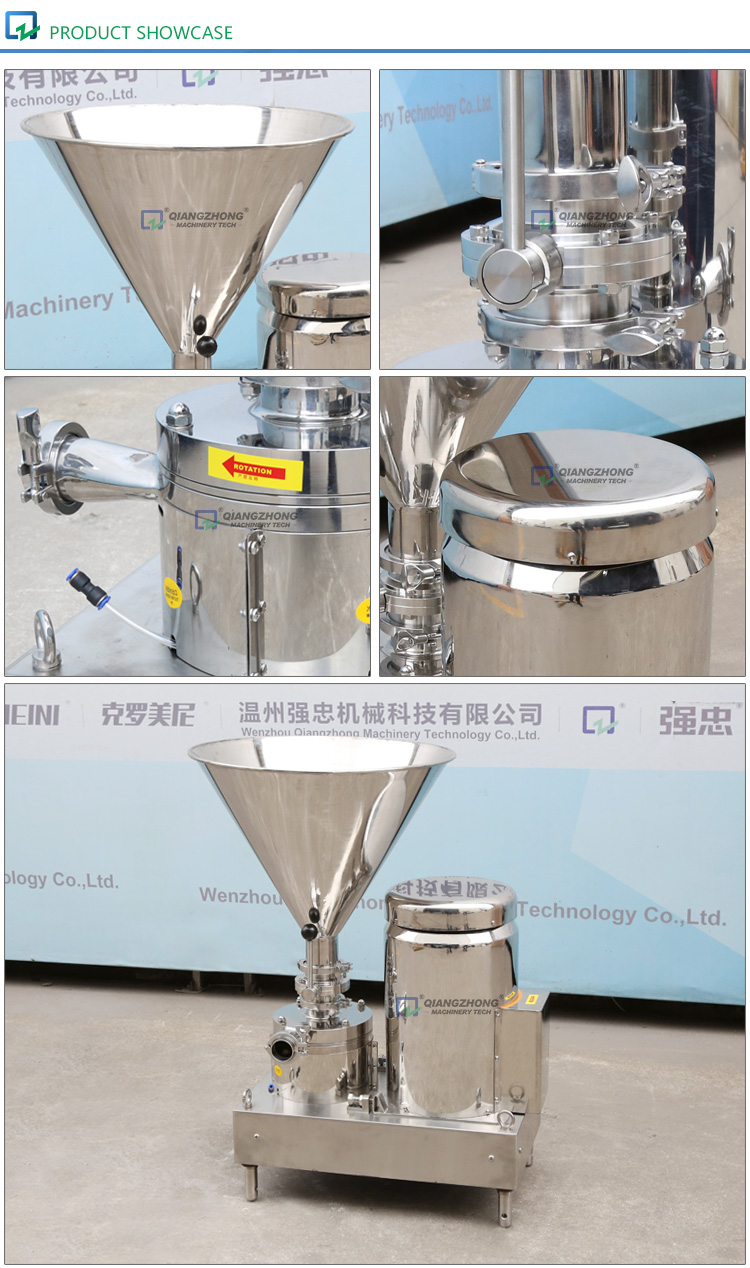

The pump is mainly composed of feeding hopper, butterfly valve, pump casing I, II, impeller, main shaft, mechanical seal, water cooling jacket, pump seat, belt transmission device, motor, etc. All parts of the equipment that are in contact with the materials are made of high-quality and corrosion-resistant stainless steel, which meets food health requirements. When the device is working, the motor drives the main shaft and the impeller through the belt, and the impeller rotates at a high speed in the pump casing II to achieve the purpose of mixing the liquid. The impeller is made of Ocr19N19, which is easy to take apart and wash, and it prevent bacteria from gathering. The mechanical seal is composed of a static ring, a dynamic seal ring, a stainless steel spring and a compression seal ring. There is also an external seal that prevents liquid leakage. The main shaft and the motor are driven by a V-belt, and the pump is equipped with a water cooling jacket and a tensioner The motor and wiring part of this pump can effectively prevent the accumulation of water and damp, and it is in line with electricity safety. The motor and the pump base are connected by bolts, which makes the whole machine can be moved arbitrarily without a fixed installation foundation.

WORKING PRINCIPLE

The mixture pump is also called water powder mixer, liquid material mixer, liquid material mixing pump, etc. It has the advantages of unique appearance, compact size, environmental protection and cleanliness, energy saving, high efficiency, rapid mixing and convenient transportation. The equipment is to fully mix the powdery material and liquid through a high speed rotating impeller to make it a required mixture and send it out. And it can absorb materials with a maximum temperature of 80 degrees. It can quickly mix the liquid material and can be used for the production of fruit juices and other beverages to achieve the desired benefits.

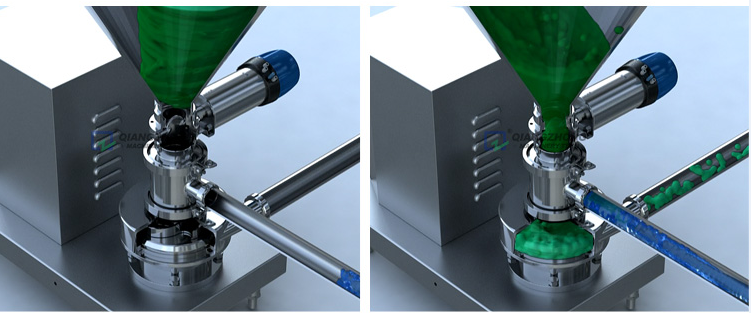

The pump consists of a main body and an impeller, which are mounted perpendicular to each other. It sucks liquids and solids separately through a double-walled pipe, preventing them from clumping before entering the main part. The liquid enters the main body of the pump at high speed and at the same time a vacuum is generated at the center of the rotor and the stator to suck solids. By adjusting the valve below the hopper, the solids can be evenly inhaled. The equipment is advanced design, multi-functional, high production efficiency and durable. It can quickly and uniformly mix a variety of solids without contact with the air, and the material is fully mixed and recycled. It can disperse and emulsify materials in the shortest time, narrowing the particle size distribution range, and finally obtaining a fine, long-term stable product.

MAINTENANCE INSTRUCTIONS